Oligonucleotide Quality Control & Quality Assurance

QUALITY CONTROL

Our ability to guarantee performance is directly related to our comprehensive understanding of oligonucleotide chemistry and synthesis platforms, our analytical systems and our experience in methods development.

Our Quality Commitment

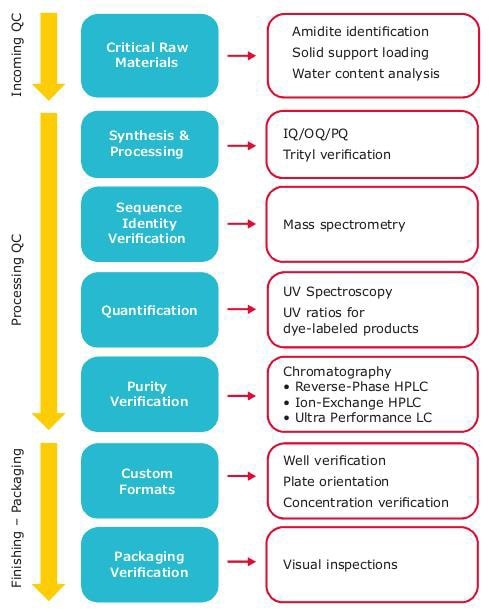

Quality is an integral part of our manufacturing process, as highlighted in Figure 1. We analyze all oligonucleotides by mass spectrometry. Complementary techniques, such as chromatography and electrophoresis, can also be used to verify specifications. Our sizable investment in state-of-the-art analytical equipment provides industry-leading tools to develop and monitor our processes. Our careful selection of software tools for peak integration, waveform deconvolution and signal processing ensures the data produced will be meaningful, useful and practical.

Having the right tools is only half the solution—our team of analytical chemists, molecular biologists and nucleic acid scientists is what truly sets us apart. Our teams collaborate to create analytical methods to support our customers’ product development and commercial requirements.

Figure 1.Quality control is used throughout the manufacturing process.

Starting Materials & Chemistry

Critical raw materials are sourced from within and include: phosphoramidites, solid-phase synthesis supports, reagents and solvents. Upon receipt of critical raw materials, incoming quality control is performed and may include water content analysis (Karl Fischer titration), phosphoramidite identification, solid support verification and acceptance based upon a Certificate of Analysis. Additionally, a rigorous supplier qualification program is part of our quality management system, which allows us to manage supplier relations and performance.

Chemistry protocols have been optimized to ensure >99.0% coupling efficiency for each nucleotide addition during synthesis. Protocols are finely tuned to synthesize both short (<35 mer) and long (>110 mer) oligonucleotides. Oligonucleotide synthesis is performed using established phosphoramidite chemistry. We routinely investigate new chemistries, including protecting groups, activators and synthesis supports to continually improve oligonucleotide quality and product portfolio expansion.

Instrumentation & Synthesis

Our in-house engineering team includes mechanical, electrical and software professionals who design and qualify our proprietary synthesis and processing equipment. Instruments are qualified through an established design review process, as well as Installation Qualification, Operational Qualification and Process Qualification (IQ/OQ/PQ) programs. An extensive preventive and prognostic maintenance program for instruments provides optimal performance, ensuring consistency and reliability. Our LIMS continuously monitors the progress of each oligonucleotide in real-time and nonconforming products are flagged for quarantine.

Sequence Identity Verification by Mass Spectrometry

Mass Spectrometry (MS) is the technology of choice for analyzing oligonucleotides. Coupled with synthesis process qualification, it ensures that the correct sequence has been synthesized. In addition, it enables sensitive detection of low levels of these by-products:

- Truncation sequences (formed by incomplete coupling, i.e. N-1, 2, etc.), sometimes called ‘shortmers’

- Deletion sequences (formed by capping failures mid-synthesis), also known as shortmers

- Depurination (unwanted hydrolytic cleavage of adenine and guanine from their respective [ribo] nucleosides)

- Incomplete removal of protecting groups, e.g. benzoyl on adenine

- Acrylonitrile adducts (formed during deprotection)

Every oligonucleotide is thoroughly characterized by MS to ensure that these by-products are below an acceptable ceiling as they can negatively affect performance, even if the correct sequence was synthesized.

Two types of MS are utilized to accomplish our commitment to 100% quality control: MALDI-TOF MS (matrix-assisted laser desorption/ionization-time of flight) and ESI-MS (electrospray ionization). Each type has advantages and disadvantages. Our different manufacturing sites use either one or both types of instruments depending on the nature of the sequences that are predominantly synthesized.

Purity Verification by Analytical HPLC

MALDI-TOF MS and ESI-MS can provide qualitative assessments of purity, while quantitative assessments are provided by RP-HPLC (reverse-phase high-performance liquid chromatography), IE-HPLC (ion-exchange high-performance liquid chromatography) and UPLC (ultra performance liquid chromatography). The method to be used depends on the nature of the oligonucleotide as well as the final specifications.

Quantification by UV Spectroscopy

An absorbance reading at 260 nm is taken of every oligonucleotide. For accuracy, multiple measurements are taken using an automated spectrophotometer equipped with path-length correction. The extinction coefficient--calculated using the industry standard ‘nearest-neighbor’ method--and Beer-Lambert Law allow for the absorbance reading to be converted to a quantity.

Analysis of siRNA Duplexes

All siRNA simplexes are analyzed by MS. In addition, our different manufacturing sites may use PAGE (polyacrylamide gel electrophoresis) to analyze duplexes depending on the nature of the sequences.

Custom Formats

As automation continues to become a focus for many laboratories, delivery of oligonucleotides in custom formats, such as 96- and 384-well plates, presents more challenges to ensure consistent quality. Product format, such as specific plates, concentration and the mixing of forward and reverse primers, necessitates detailed specifications. Additional quality control measures are in place to verify accuracy for custom formats.

Final Inspection

All products are subjected to a final visual inspection prior to packaging. Inspections provide a final assurance that finished products are in the correct formats, correctly labeled and ready for immediate use.

Quality Assurance

At the foundation of our manufacturing processes is a robust Quality Management System (QMS), which drives compliance to our following Quality Registrations:

- ISO 9001:2015 for manufacturing research-grade oligonucleotides

- ISO 13485:2016 for manufacturing diagnostic-grade oligonucleotides

- ISO 14001:2015 for effective environmental management

This quality culture is integrated into all aspects of our business. Key components of our QMS include:

- Certificates of analysis

- Document control

- Change notification

- Vendor management

- Business agreements

- Corrective and preventive actions

Each component drives quality assurance, and for verification, we routinely host rigorous registrar, internal, and customer audits.

Conclusion

Several analytical techniques are available for performing quality control on oligonucleotides, including 100% mass spectrometry.

To continue reading please sign in or create an account.

Don't Have An Account?