Self-Assembly Materials in Advanced Technologies

Introduction

Self-assembled monolayers (SAMs) are single-molecule-thick organic films that spontaneously form on solid surfaces, crucial for surface engineering. They enable precise control over surface properties through specific molecular structures and strong chemical interactions, making them significant in research and industry.

What Are Self-Assembled Monolayers?

SAMs are organized layers of molecules that form via a "bottom-up" process. They consist of three key components:

- Head Group (Anchor): This functional group forms strong chemisorption bonds with the substrate. For example, thiols bond with gold, achieving an interaction energy of about 45 kcal/mol, while silanes create stable siloxane bonds with silicon oxide (SiO₂).

- Linker Chain (Spacer): Typically, a long alkane chain, this component provides structural order through van der Waals interactions, resulting in a dense, crystalline-like structure.

- Terminal Group (Tail): The outer surface consists of terminal groups (e.g., methyl, hydroxyl, carboxyl), allowing customization of surface properties for hydrophobic or hydrophilic characteristics.

Importance of SAMs

SAMs play a vital role in modifying surfaces across various applications. In nanotechnology, they enable the fabrication of sensitive nanoscale devices and sensors. In biomedicine, SAMs enhance drug delivery systems, improving therapeutic efficacy and reducing side effects. In the electronics industry, they serve as effective crosslinkers, aiding adhesion between different materials, which is essential for device manufacturing and composite materials.

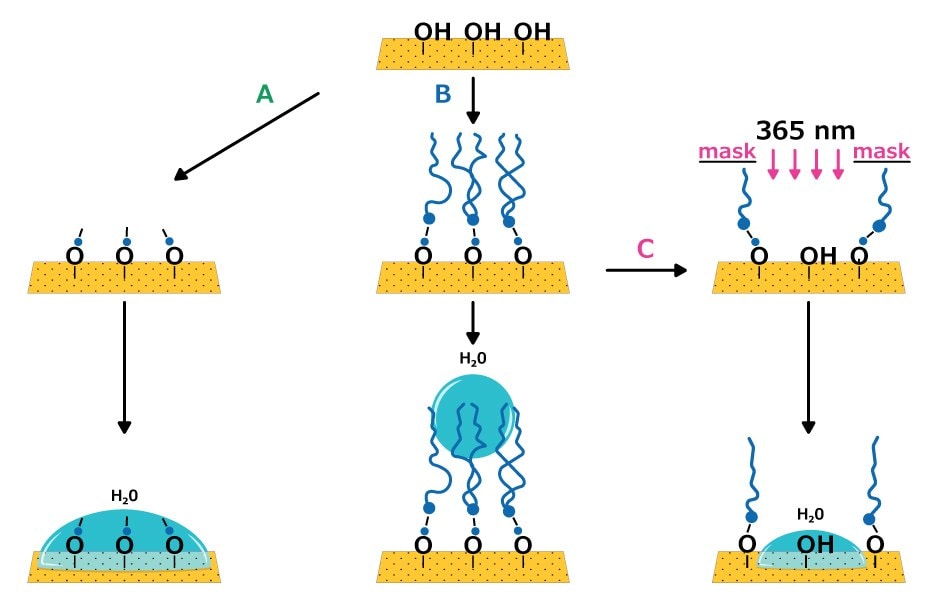

The length of the alkyl chain in a self-assembled monolayer (SAM) is a crucial design parameter influencing the film's structural integrity, packing density, and surface properties. Short alkyl chains typically lead to less ordered and less densely packed films due to weaker van der Waals forces, resulting in more defects. These shorter SAMs are useful when substrate access or specific terminal group chemistry is essential, such as in biosensor applications. In contrast, long alkyl chains enhance packing and molecular order due to stronger van der Waals forces, resulting in low surface roughness. Long-chain SAMs terminated with methyl (-CH₃) groups are stable and hydrophobic, making them suitable for protective coatings. However, to achieve anti-adhesive, "protein-repellent" surfaces, specific hydrophilic terminal groups, like oligo (ethylene glycol) (OEG), are required to create a highly hydrated outer layer that repels biological matter as displayed in Figure 1.

Figure 1.Schematic representation of self-assembled monolayer (SAM) surface modification. Panel A (Short Alkyl Chain Silanes): Create less ordered films suitable for biosensor spacing and molecular electronic junctions, enabling single-molecule device fabrication. Panel B (Long Alkyl Chain Silanes): Form dense, highly ordered, hydrophobic surfaces that enhance charge injection efficiency in OLEDs and provide durable, water-repellent industrial coatings. Panel C (Photopatterned Long Alkyl Chain Silanes): Used in nanolithography to create nanoscale patterns, which enables precise control of cell adhesion for advanced biomedical applications and patterned biosensing platforms.

Surface Chemistry & Functionalization (SAM Selection Guide)

By utilizing silane compounds and thiols, our self-assembly materials, available in the highest purities on the market, provide precise surface modification through wide range of functionalities, supporting effective solutions in various research applications, from biomedical devices to nanoelectronics.

An overview of common SAM-forming compounds, their typical applications, and the surface properties they provide, addressing the nuances of hydrophobicity/hydrophilicity and bio-interaction, is listed in Table 1.

Regarding deposition methods, SAMs precursors can be deposited onto substrates through gas or solvent.4

Key Applications

The following sections explore how SAMs and silane-based adhesion layers enable advanced functionalities across diverse domains—from nanoelectronics to biomedicine—by tailoring surface properties at the molecular level.

Molecular Interface Engineering in Nanoelectronics

Self-assembled monolayers (SAMs) are vital in nanoelectronics, offering a cost-effective, bottom-up approach for precise molecular-scale surface engineering.

Surface Modification & Defect Passivation

SAMs optimize material properties and device integration by modifying interfaces. They provide robust barriers against environmental degradation, enhancing the longevity of sensitive nanoscale components. SAM coatings passivate surface traps and defects in semiconductors, boosting charge carrier mobility and device stability.8

Interface Engineering- Sensing Interface

SAMs are vital for immobilizing biological sensing probes,9 providing stable surfaces for attaching antibodies, enzymes, and DNA, which enhances the sensitivity and specificity of biosensors for detecting analytes like glucose and pathogens. Common examples include 11-mercaptoundecanoic acid on gold substrates and octadecyltrichlorosilane (OTS) on oxide surfaces. SAMs facilitate effective bioreceptor attachment while minimizing nonspecific adsorption, making them integral to high-performance biosensor design across various applications, including healthcare and environmental monitoring.

Patterning Nano and Micro Systems

SAMs are employed in soft lithography (specifically microcontact printing) and photolithography (using UV light or e-beam irradiation) for patterning, creating selective regions for material deposition or etching, which is crucial for defining nanoscale circuit features.10

Biomedicine & Drug Delivery

In biomedicine, silane adhesion layers, particularly 3-aminopropyltriethoxysilane (APTES) and 3-aminopropyltrimethoxysilane (APTMS), act as essential molecular linkers for surface functionalization. They form stable covalent bonds between inert inorganic materials and bioactive molecules. These silanes serve as versatile adhesion promoters and bioconjugation platforms, enabling precise control over the material-biology interface to enhance implant integration, biosensors and facilitate advanced drug delivery systems.

Biomedical Implants

Silanes modify biologically inert oxide substrates like titanium and silicon oxide by forming stable siloxane bonds (Si-O-Si) with hydroxyl groups (-OH), creating a durable adhesion layer. Organosilanes such as APTES serve as bifunctional agents: one end anchors to the substrate, while the other has a reactive amine (-NH₂) for attaching bioactive molecules.11 This promotes cell adhesion with RGD peptides or collagen, enhancing osteoblast activity and osseointegration. Antimicrobial agents can also be added to prevent infections, while modifications improve biocompatibility and reduce inflammation.

Targeted Drug Delivery

In drug delivery, organosilanes such as APTES functionalize nanoparticles (e.g., graphene oxide1) with amine groups and enhance drug loading capacity through electrostatic interactions with negatively charged drugs. These amine groups can also act as pH-responsive "nanogates." In neutral blood, the gates remain closed to prevent premature leakage, but in the slightly acidic environment of a tumor, they open to release the drug in a controlled manner. Additionally, organosilanes provide stable attachment sites for targeting ligands, such as antibodies, allowing precise delivery to specific cells or tissues while minimizing systemic side effects.

Nanocomposite Manufacturing

Among popular SAMs for nanocomposites, 3-Glycidoxypropyltrimethoxysilane (GPTMS) and APTES are crucial for advanced composites manufacturing.3 These SAMs act as coupling agents between inorganic fillers, like carbon fiber, and the polymer matrix, creating strong interfaces suitable for durable adhesive demanding applications. Its versatility highlights the broad potential of silanes in developing robust materials for structural and protective applications.

Recent Advancements

Recent advancements in advanced electronics research highlight the role of self-assembled monolayers (SAMs) in achieving molecular-level control for fabricating molecular junctions. This precision is vital for applications in quantum computing and spintronics, where both vertical and lateral control of single molecules is essential.

Researchers are enhancing SAMs to develop complex interfaces for diagnostic and environmental sensors, including tailored biosensors for selective2 molecule capture and optimized microfluidics6 for precise liquid flow. Integrating SAMs with nanomaterials like MXenes2 boosts surface area and signal amplification, facilitating robust, label-free biosensors for point-of-care diagnostics and wearable health devices while promoting miniaturization.

Recent innovations using GPTMS with alkyl(trialkoxy)silanes have produced eco-friendly superhydrophobic surfaces on cotton fabrics12, achieving water contact angles over 150°. These surfaces prevent non-specific binding in sensor applications and enhance functional textiles by repelling water and stains. APTES and APTMS demonstrate optimal bonding, improving hydrophilicity through hydrogen bonding and siloxane crosslinking.

In response to environmental regulations against toxic biocides, researchers are developing non-toxic anti-fouling coatings13 that mimic natural surfaces like shark skin and lotus leaves. Hydrophilic SAMs, such as OEG-terminated layers, create dense water barriers that inhibit protein and marine organism adhesion, promoting self-cleaning and fouling deterrence.

Conclusion

In conclusion, self-assembly materials, especially those leveraging the diverse chemistry of silane compounds and thiols, are at the forefront of advancing technologies across multiple scientific and engineering fields. Their ability to precisely modify surface properties and facilitate complex functionalization opens numerous possibilities for innovative applications, from targeted medical treatments to robust industrial coatings. The continued development and application of these materials reinforce their profound significance in both cutting-edge research and practical technological implementations.

Reference

To continue reading please sign in or create an account.

Don't Have An Account?