Column Packing and Preparation for Affinity Chromatography of Antibodies

Prepacked columns from Cytiva will ensure reproducible results and the highest performance.

Use small prepacked columns for chromatography media scouting and method optimization and to increase efficiency in method development.

Efficient column packing is essential for AC separation, especially when using gradient elution. A poorly packed column gives rise to poor and uneven flow, band broadening, and loss of resolution. If column packing is required, the following guidelines will apply at all scales of operation:

- With a high binding capacity medium, use short, wide columns (typically 5 to 15 cm bed height) for rapid purification, even at low flow velocity.

- The amount of AC medium required will depend on the binding capacity of the medium and the amount of sample. Binding capacities for each medium are given in this handbook and supplied with the product instructions. Estimate the amount of medium required to bind the sample of interest and use five times this amount to pack the column. The amount of medium required can be reduced if resolution is satisfactory.

- Once separation parameters have been determined, scale up a purification by increasing the diameter of the column to increase column volume. Avoid increasing the length of the column, if possible, as this will alter separation conditions.

AC media can be packed in either Tricorn, XK, or HiScale® columns available from Cytiva (Figure A5.1).

Figure A5.1.Column packing in progress.

- Equilibrate all materials to the temperature at which the separation will be performed.

- Eliminate air by flushing column end pieces with the recommended buffer. Ensure no air is trapped under the column net. Close column outlet leaving 1 to 2 cm of buffer in the column.

- Gently resuspend the medium.

Note that AC media from Cytiva are supplied ready to use. Decanting of fines that could clog the column is unnecessary.

Avoid using magnetic stirrers since they can damage the chromatography matrix.

- Estimate the amount of slurry (resuspended medium) required on the basis of the recommendations supplied in the instruction manual.

- Pour the required volume of slurry into the column. Pouring down a glass rod held against the wall of the column will minimize the introduction of air bubbles.

- Immediately fill the column with buffer.

- Mount the column top piece/adapter and connect to a pump.

- Open the column outlet and set the pump to the desired flow rate (for example, 15 mL/min in an XK 16/20 column).

When slurry volume is greater than the total volume of the column, connect a second glass column to act as a reservoir (see Ordering information for details). This ensures that the slurry has a constant diameter during packing, minimizing turbulence and improving column packing conditions.

If the recommended flow rate cannot be obtained, use the maximum flow rate the pump can deliver.

- Maintain the packing flow rate for at least 3 CV after a constant bed height is obtained. Mark the bed height on the column.

Do not exceed 70% of the packing flow rate during any purification.

- Stop the pump and close the column outlet. If a second column has been used: Remove the top piece and carefully fill the rest of the column with buffer to form an upward meniscus at the top. Insert the adapter into the column at an angle, ensuring that no air is trapped under the net.

- Slide the adapter slowly down the column (the outlet of the adapter should be open) until the mark is reached. Lock the adapter in position.

- Connect the column to the pump and begin equilibration. Reposition the adapter if necessary.

The medium must be thoroughly washed to remove the storage solution, usually 20% ethanol. Residual ethanol can interfere with subsequent procedures.

Many chromatography media equilibrated with sterile phosphate-buffered saline containing an antimicrobial agent may be stored at 4 °C for up to 1 mo, but always follow the specific storage instructions supplied with the product.

Column Packing and Efficiency

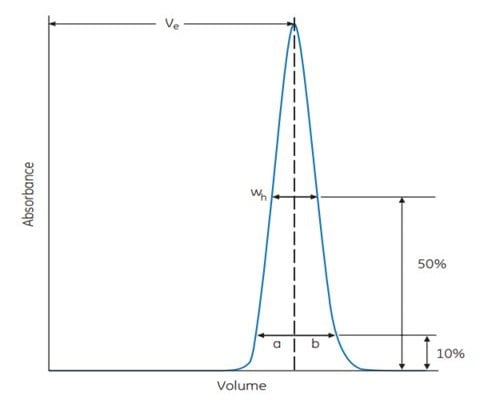

Column efficiency is expressed as the number of theoretical plates per meter chromatography bed (N) or as H (height equivalent to a theoretical plate, HETP), which is the bed length (L) divided by the plate number. Column efficiency is related to the band broadening that can occur on a column and can be calculated from the expression:

VR = volume eluted from the start of sample application to the peak maximum

wh = peak width measured as the width of the recorded peak at half of the peak height

H is calculated from the expression:

L = height of packed bed.

Measurements of VR and wh can be made in distance (mm) or volume (mL) but both parameters must be expressed in the same unit.

Column performance should be checked at regular intervals by injecting acetone to determine column efficiency (N) and peak symmetry (asymmetry factor, As). Since the observed value for N depends on experimental factors such as flow rate and sample loading, comparisons must be made under identical conditions. In AC, efficiency is measured under isocratic conditions by injecting acetone (which does not interact with the medium) and measuring the eluted peak as shown in Figure A5.2.

Figure A5.2.Measurements taken to calculate column efficiency.

As a general rule, a good H value is about two to three times the average particle diameter of the medium being packed. For a 90 µm particle, this means an H value of 0.018 to 0.027 cm.

The asymmetry factor (As) is expressed as:

where

a = First half peak width at 10% of peak height

b = Second half peak width at 10% of peak height

As should be as close as possible to 1.0. A reasonable As value for a short column as used in AC is 0.80 to 1.80.

An extensive leading edge is usually a sign that the medium is packed too tightly and extensive tailing is usually a sign that the medium is packed too loosely.

Run at least 2 CV of buffer through a newly packed column to ensure that the medium is equilibrated with start buffer. Use pH monitoring to check the pH of the eluent.

Custom column packing

A service for packing of laboratory columns or filling of 96-well plates is supplied when columns or plates with suitable chromatography media are not available from the standard portfolio. The Custom Products group works in close collaboration with you to deliver packed columns for specialized purification requirements.

Column Selection

Tricorn, XK, and HiScale® columns are fully compatible with the high flow rates allowed by with modern media, and a broad range of column dimensions are available (Table A5.1).

In most cases the binding capacity of the medium and the amount of sample to be purified will determine the column size required. Also, Empty Disposable PD-10 Columns are available for single-use applications using gravity flow.

Cleaning of Protein G and Protein A Sepharose media

After purification, the medium should be regenerated as follows:

- After elution, wash with 2 to 3 column volumes of elution buffer.

- Immediately re-equilibrate by washing with 2 to 3 column volumes of binding buffer.

Cleaning-in-place

When an increase in backpressure is seen, the medium should be cleaned. In some applications, substances like denatured proteins or lipids do not elute in the regeneration procedure.

To remove precipitated or denatured proteins:

- Wash the medium with 2 column volumes of 6 M guanidine hydrochloride.

- Immediately wash with at least 5 column volumes of binding buffer.

To remove strongly bound hydrophobic proteins, lipoproteins and lipids:

- Wash with a nonionic detergent, for example, 0.1% Triton X-100 at 37 °C for 1 min.

- Immediately wash with a least 5 column volumes of sterile binding buffer.

a) Alternatively, wash the column with 70% ethanol and let it stand for 12 h.

After treatment, wash with at least 5 column volumes of binding buffer.

Reversed flow can improve the efficiency of the cleaning-in-place procedure. After cleaning, store in 20% ethanol.

Washing with 70% ethanol will increase backpressure. Use a lower flow rate when cleaning with 70% ethanol.

Cleaning of MabSelect media

All MabSelect media can be cleaned using the following procedures:

To remove precipitated or denatured substances:

- Wash the medium with 2 column volumes of 50 mM sodium hydroxide in 500 mM sodium sulfate, or 50 mM sodium hydroxide in 1 M sodium chloride, or 100 mM sodium phosphate, or 6 M guanidine hydrochloride in 10 mM sodium hydroxide. Contact time: at least 10 min.

- Immediately wash with at least 5 column volumes of sterile filtered binding buffer at pH 7.0 to 8.0.

MabSelect SuRe and MabSelect SuRe LX are alkali-tolerant, allowing the use of more concentrated solutions of sodium hydroxide:

- Wash with 3 column volumes of binding buffer.

- Wash with at least 2 column volumes of 100 mM to 500 mM sodium hydroxide. Contact time: 10 to 15 min.

- Immediately wash with at least 5 column volumes of sterile and filtered binding buffer at pH 7.0 to 8.0.

To remove strongly bound hydrophobic proteins, lipoproteins, and lipids:

- Wash with 2 column volumes of a nonionic detergent (e.g., 0.1% solution).

- Immediately wash with at least 5 column volumes of sterile filtered binding buffer at pH 7.0 to 8.0.

a) Alternatively, wash with 3 to 4 column volumes of 70% ethanol or 30% 2-propanol. Wash immediately with at least 5 column volumes of sterile filtered binding buffer at pH 7.0 to 8.0. Apply increasing gradients to avoid air bubble formation when using high concentrations of organic solvents.

Washing with 70% ethanol and 30% 2-propanol will increase backpressure. Use a lower flow rate when cleaning with 70% ethanol or 30% 2-propanol.

Materials

To continue reading please sign in or create an account.

Don't Have An Account?