Antibody Drug Conjugate Manufacturing

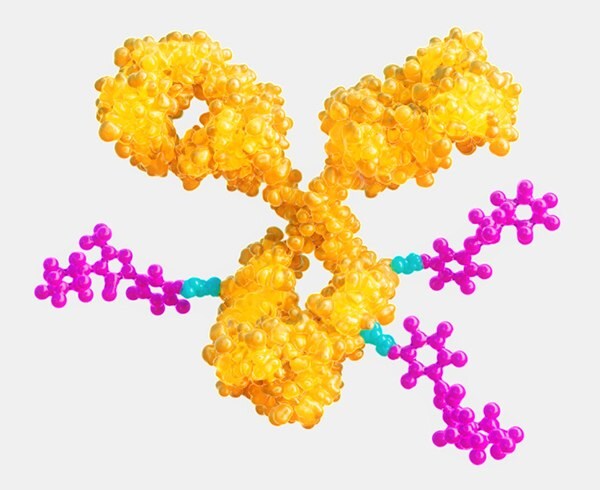

Antibody-drug conjugation (ADC) technology uses monoclonal antibodies (mAbs) to deliver potent, highly active pharmaceutical ingredients (HPAPIs) to targeted cells. In conjugated form, HPAPIs exhibit selective cytotoxicity which can spare non-target cells from toxic effects. Realizing the vast potential of ADC technology, however, is challenging and complex. Advanced manufacturing suites and dedicated equipment are necessary to characterize the molecule and demonstrate its purity, homogeneity, and stability. Efficiently linking a unique, tumor targeted mAb to a potent, cell-killing cytotoxic small molecule drug is only the beginning—meeting ADC manufacturing needs requires a comprehensive portfolio of products and wide-ranging expertise in small and large molecule development, manufacturing, and testing. |

Related Product Resources

Analytical Development and Product Characterization

Article: What makes a good ADC?

White Paper: Know your ADC’s Critical Quality Attributes

Webinar: The Benefits of Using Orthogonal Analytics in ADC Drug Development

Webinar: The Butterfly Effect: How to See the Impact of Small Changes to Your ADC

Webinar: Integrated Approach to Support ADC Programs From Concept to Clinical Material

Poster: Correlation of Discreet Drug-linker Variations on ADCs to Binding Activity

Antibody, Linker-Payload and Conjugation Services

Brochure: Discover Comprehensive ADC Services and Solutions

Webinar: Accelerated ADC Development with Integrated Supply Chain Solutions

Flyer: ADC Express™ Pre-clinical Conjugation Services for the Best Candidate Selection

White Paper: Commercializing Antibody-drug Conjugates: a CMO’s Journey

Linker-Payload Technology

White Paper: Benefits of Monodisperse and Activated PEGs in ADC Development

Flyer: Flyer: DM1 - Mertansine GMP Quality Payload For Your Drug Conjugate Programs

Flyer: Synthesise Dolastatin Payloads Faster and with Less Risk

Webinar: Payloads to Accelerate the Clinical Path

Processing Portfolio

Brochure: Biopharmaceutical and ADC Processing Portfolio

Biopharmaceutical and ADC Process Application Guide

Data Sheet: Eshmuno® CMX mix-mode chromatography resin

Webinar: Exploring enhanced selectivity of innovative ion exchange resin in ADC polishing

Single-use Template

Webinar: Tackling the Challenges of Single-use Manufacturing for ADCs

Case Study: Complete Single-use ADC technology, from development to scale-up

Application Note: Compatibility of a Mobius® Single-use Solution for ADC processing

Poster: Mobius® Single-use ADC Technology Supporting ADC Processing

Application Note: Pellicon® Capsules for Ultrafiltration/Diafiltration of ADCs

Webinar: Single-use TFF Capsules for mAb and ADC Processing

Keys to a Strong ADC PartnershipA seamless supply chain from gene sequence to stability testing of final drug product can reduce time to market by minimizing development and manufacturing complexity.

|

Workflow

Finding the Missing Link for Your Payload Supply

A highly active payload and drug-linker are matched with the mAb for eventual conjugation into an antibody drug.

Monodisperse and activated PEGs, or Chetosensar™ technology may solve solubility challenges during drug discovery and development. Advanced payload intermediates for the most common classes of payloads can help to reduce development timelines.

Connecting the Dots with Conjugation Services

The developed components of cell line, antibody, payload, and linker come together during conjugation and/or bioconjugation.

ADC Bulk Drug Substance (BDS) Testing Services

BDS as well as final drug product receive extensive analytical testing, including stability and release testing.

Conjugation with Cytotoxic Molecule

Linkage between the antibody and a highly active payload is a critical component of an ADC, requiring a broad range of products and chemicals.

Chromatography (Optional)

An optional chromatographic step can be used to remove high molecular weight species such as antibody aggregates and free drug residuals, while supporting optimization of drug-antibody-ratio (DAR) and control of polydispersity.

The Eshmuno® CMX resin has been designed for highly selective mixed mode chromatography.

Ultrafiltration/Diafiltration

Removing residual solvent and free drug after conjugation is necessary prior to preparation of the final formulation with the desired concentration and buffer.

The Pellicon® Capsule is the first of its kind–a true single-use TFF device that comes ready to process ADCs in minutes.

Sterile Filtration

Sterilizing-grade filtration is under increasingly intense scrutiny by regulatory bodies, requiring a high degree of sterility assurance.

Millipore Express® high area capsules and cartridges with SHC hydrophilic filters under Categories.

ADC BDS Final Fill and Formulation

The BDS is prepared for a final and unique formulation. The lyophilized dosage form is preferred and usually contains a buffer, stabilizer (e.g, trehalose or sucrose), and surfactant.

To continue reading please sign in or create an account.

Don't Have An Account?