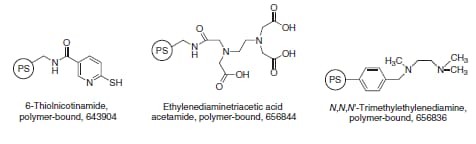

Metal Scavengers

Metal compounds are widely used in organic and medicinal chemistry as either reactants or catalysts. Because most metal ions have physiological activities, reducing residual metal levels has become a key step in syntheses of bioactive compounds.1 Application of resin scavengers is an efficient method to remove metal ions during post-synthesis purification.2 We have developed several different functionalized resin scavengers to remove metals in a variety of organic syntheses.

Typical Procedure of Removal Metals

Add 3–5 eq. of resin scavenger to an organic solution of crude product containing metal ion. The resulting mixture is stirred for 4–16 h at room temperature to allow the scavenger to fully bind to the metal ions. In some cases, the addition of a few drops of water to the solution is necessary to increase the binding rate. The scavenger is then removed by filtration.

Maximum Binding Capacity of Scavengers

The maximum binding capacity of the scavenger was determined by stirring a mixture of a scavenger (1 eq.) and a metal salt (2.5–4 eq.) in an organic solvent (THF, MeOH, EtOH, dichloromethane) or a mixture of two solvents overnight. The resin was filtered and washed with solvent, dried, and then analyzed for metal content by microanalysis.

References

To continue reading please sign in or create an account.

Don't Have An Account?