Substrate and Conductor Materials Towards More Sustainable Electronics

Introduction

E-waste accumulation poses an escalating issue for society as end-of-life electronics are not circulated, recycled, or managed efficiently. At the same time, the accelerating consumption of raw materials threatens the availability of limited resources. The European Green Deal and Circular economy action plan work to address these challenges through ecological products and increased circulatory work. Additionally, the EU (European Union) Ecodesign Directive is being revised beyond currently emphasized energy efficiency practices to support a full circular economy, including the use of natural resources by maximizing their value and minimizing their waste. Both plans seek to improve the circularity of raw material substrates and active materials via manufacturing methods, circular design, and eco-design principles (such as efficient recovery processes). In this mini review, we will highlight the possibilities of renewable substrates and conductive materials, with particular attention paid to flexible electronics.

Towards Sustainable Substrates

Electronic products are usually fabricated on fossil fuel-based substrates, such as plastic composite FR4 or plastics like polyimide (Cat. No. GF77686521) or polyethylene terephthalate (PET, Cat. Nos. GF09063581, GF25214475, GF32099272, GF48528591, GF89357619). These are characterized according to process compatibility and suitability for varying application requirements, such as elevated temperature, humidity tolerance, and fire retardancy. However, these substrates have a high environmental impact due to reliance on non-renewable raw materials, limited recyclability, and excess material consumption (thicknesses, etc.). More ecological substrate alternatives for electronics can be found among cellulose and wood-based materials, such as paper-based products,1 and bioplastics, such as poly lactic acid (PLA, Cat. Nos. 764620, 764612, 767344).2 Silk fibroin, nanocellulose, and nanochitin are also referenced resources.3,4 Although these materials do not possess as good fire retardancy as traditional electronic substrates, their properties can be improved with special coatings, such as bio-based fire retardants.5 These substrate materials are thin and flexible and, therefore, compatible with sustainable printing-based manufacturing processes that require lower material and energy consumption than etching-based processes.6,7 However, electric functionality demands specific parameters for surface roughness and adhesion, mechanical durability, temperature stability, moisture tolerance, and eco-friendly substrate alternatives can face challenges in meeting these targets. For example, biodegradability is a desirable property of printed electronics used in applications that terminate in a natural environment. Immonen et al.5 have shown that wood and paper-based substrates have relative biodegradability between 33–52% (compared to a microcrystalline cellulose standard). In contrast, biopolymer substrates can have an even higher degradation rate.19 Fossil-based and bio-based electronic substrates are compared in Table 1.

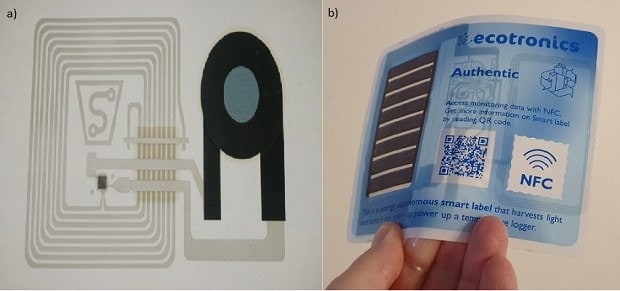

Figure 1.Examples of electronic devices on sustainable substrates: a) anti-counterfeit label consisting of printed electrochromic display and Near Field Communication (NFC) antenna on paper substrate. Reprinted with permission from reference 20, copyright 2018 American Chemical Society. b) energy autonomous temperature logger based on printed Organic Photovoltaic (OPV) and supercapacitor, and NFC communication on bio-plastic PLA substrate. Reprinted with permission from reference 25, copyright 2016 MDPI.

Conductive Materials Beyond State-of-the-art

Although substrates constitute bulk electronic circuit waste, the components, electrical leads, and soldering materials also contain scarce and/or environmentally harmful materials. While copper is traditionally used as the lead material in FR4-based PCBs, silver represents the state of the art in printed and flexible electronics due to excellent printing ink properties and general environmental stability, retaining these qualities even in particulate form and low-temperature processing. However, silver is well known as an anti-bacterial material and thus harmful to the natural environment, requiring recovery and recycling of the material, which are both cost and energy-intensive processing procedures.10 Furthermore, silver is becoming a scarce resource and increasingly expensive to extract from natural sources. Consequently, various methods to reclaim silver are in development.21

Copper tracks in standard PCBs are made by etching, resulting in significant waste material that renders them unsuitable as ecological substrates. However, printable copper-based materials have been developed and are increasingly attractive as silver alternatives when careful steps are taken to reduce copper oxidation.22,23 The sintering process is one of the key shortcomings of copper-based inks. However, converting resources completely to bulk copper can help the material achieve electrical conductivity analogous to printed silver. Because this process is conducted at low temperatures, it qualifies as an ecological substrate and flexible material. Current inks can be sintered at temperatures as low as 130–140 °C.24

It has been shown that the impact of switching from silver to copper (Cat. No. 901889) in printed antenna board manufacturing reduced the global warming potential by 28%. When implemented on a large scale, switching from silver to copper would bring significant reduction potential to printed electronics.19 Mixing silver with more renewable materials such as graphene can also reduce silver usage.25 Table 2 illustrates that silver is unsustainable as a conductor material as the material supply is already threatened.26 Copper supply is currently maintained, but the availability is limited from conventional sources. However, carbon in this context (not as carbon-based fuel) is abundant, and no supply issues are anticipated.

Carbon-based conductors are ideal from an environmental and ecological perspective, provided they demonstrate sufficient conductivity for the intended application. They can be produced and applied without using unsustainable chemicals, high energy processing, or water consumption. From a material property perspective, graphene (Cat. No. 900561), graphene nanoribbons (Cat. Nos. 922714, 922676), and carbon nanotubes (Cat. Nos. 901019, 698849, 755125) show superior electrical conductivity compared to metals including copper and silver (~106 S/cm). Still, in application, interfaces between high conductivity domains limit conductivity, resulting in a practical conductivity of 1–0.1 % of the metal conductivity.27 Carbon conductivity can be increased with doping, adding processing steps and cost. However, doped graphene fibers can almost reach the level of Al/Cu/Ag wires.

In general, printing ink production can be conducted using either solvent or water-based formulations. The desired application determines the suitability of water-based ink, as it usually is not compatible with hydro-phobic substrates, and the adhesion of water-based printed features is typically lower than that of solvents. Water-based ink generally requires higher drying temperatures and longer drying times, increasing environmental impact. That said, solvent-based inks emit toxic Volatile Organic Compounds (VOCs), and their effect on sustainability will depend entirely on the ability of the production facility to manage emissions.28 When using printed silver nanoparticles, the contribution of conductors is typically the primary factor in environmental consequences, while the influence of other chemicals is much lower.6

Aluminum is a low-cost, abundant alternative to both copper and silver. While not directly environmentally hazardous, it is energy intensive to produce and recycle. Aluminum oxidizes very easily, but when applied in thick layers, its native surface oxide protects the lower levels from further oxidation. Therefore, aluminum is best applied in a thick layer as particle-based systems are impractical due to oxidation. Patterned layers of aluminum can be applied by foil transfer via various methods, the most common being thermal foil transfer.29

Conclusion

Circular design enabling reusability and recyclability of electronics is critically important alongside waste stream management and material recovery. The work towards sustainable substrates is well underway and increasing effort is being directed towards more sustainable conductors. Optimistically, the first novel material recovery based on biodegradable substrates has been reported.30 We anticipate these advances will be joined by renewable active components via bioelectronics in addition to the further exploitation of these materials’ intrinsic properties.

Related Products

References

To continue reading please sign in or create an account.

Don't Have An Account?