Towards Greener Organic Transistor Sensors

Introduction

In our heavily industrialized world, the manufacture and disposal of electronic devices comes at a vast environmental cost. Therefore, there is a pressing need for greener electronics that thoroughly minimize environmental impact. For electronic goods, this means efficiency, sustainability, and non-toxicity at every stage of an item’s lifecycle, from sourcing raw materials to the final disposal. Organic electronic devices present unique opportunities and challenges in this area. Unlike conventional silicon-based devices, organic electronics have great intrinsic potential to be environmentally friendly. This potential is rarely fully realized in the research laboratory or in devices already on the market.

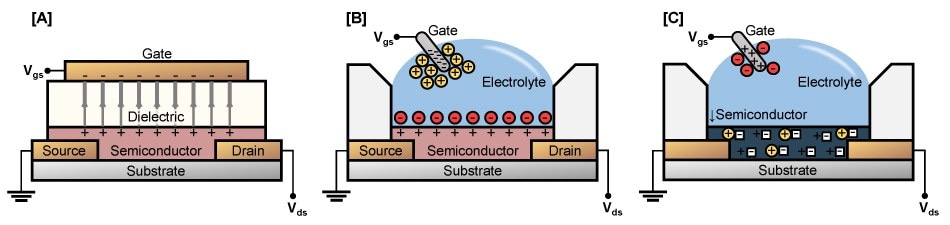

An important application for organic electronics is sensing biological or chemical analytes using organic thin film transistors (OTFTs). Practical uses for OTFT sensors include health diagnostics and monitoring, such as rapid identification of viruses to aid pandemic responses and chemical detection in industry and the environment. OTFTs are three-terminal devices where the current passing through a semiconductor between the source and drain electrodes is regulated by the voltage applied at the gate electrode. An OTFT is composed of a substrate, conductors for the electrodes, an organic semiconductor, and either an insulator or an electrolyte. Figure 1 shows how these components are used in some common OTFT architectures. An OTFT sensor will also typically include a recognition element, such as an ion-selective membrane or enzyme, to selectively interact with a specific analyte. Sustainability and environmental concerns can be raised about each component of the device. This review will briefly consider each layer, highlighting examples of recent or noteworthy work toward improving sustainability, safety, and biodegradability.

Figure 1.Schematics of common OTFT architectures (cross-sectional view). A) An organic field effect transistor (OFET), gated by a solid dielectric. B) An electrolyte gated OFET (EGOFET), where ions accumulate at the semiconductor boundary. Wells are often used to contain the electrolyte. C) An organic electrochemical transistor (OECT), where ions are injected into the semiconductor.

Substrates

The substrate provides strength and support for the OTFT, constituting the bulk of its volume and mass and making it of critical environmental concern. In research literature, silicon wafers and glass are standard choices, but flexible polymer substrates, such as polyethylene terephthalate (PET), are also widely used. Work on greener substrates has focused on naturally sourced materials that readily biodegrade.

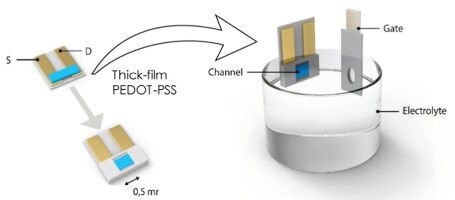

Paper is a feasible option for ecologically sourced, low-cost, and biodegradable alternative substrates. However, the surface properties of raw paper are rarely suited to the deposition of organic films due to the roughness and porosity of the paper. Smooth surfaces are essential for limiting the formation of defect states, thus enabling higher transistor performance.1 Therefore, coatings are usually required on rough paper substrates. In one recent study, an organic electrochemical transistor (OECT) sensitive to hydrogen peroxide (H2O2) was fabricated on microporous commercial photo paper (Figure 2).2 In another study, a specialized paper with non-porous, hydrophilic coatings was used as the substrate for inkjet-printed organic field effect transistors (OFETs).3 A downside of using coatings is that they potentially compromise the overall sustainability and biodegradability of the substrate. Sometimes, a coating can be avoided altogether.4,5 Naturally derived paper coatings have also been tested for OTFT substrates, such as chitosan (Cat. No. 419419, 448877, 448869),1 a biodegradable polymer derived from the shells of crustaceans. The chitosan coating dramatically improved the root mean square roughness values of the substrate, from 11.3 nm on bare paper to 2.01 nm when coated.1 An important environmental consideration for any solution-processed material is the solvents used. Toxic solvents, such as halogenated compounds like chloroform, are best avoided, whereas water and alcohols are considered safer. Chitosan is exemplary in this respect, being readily dissolved in water with 2% (v/v) acetic acid (Cat. No. 338826).1 It is also beneficial that few other solvents dissolve chitosan, meaning additional solution-processed layers can be deposited without risking damage to the chitosan coating.

Several other materials have also been proposed for environmentally friendly substrates. This includes standalone chitosan films,6 polylactide or poly(lactic acid) (PLA, Cat. No. 38534), a thermoplastic derived from natural plant sugars,7 and shellac, a resin secreted by certain insects.8

Figure 2. An OECT hydrogen peroxide sensor using photo paper as the substrate. Reproduced under Creative Commons license (CC BY 4.0) from reference 2, copyright 2021 American Chemical Society.

Electrodes

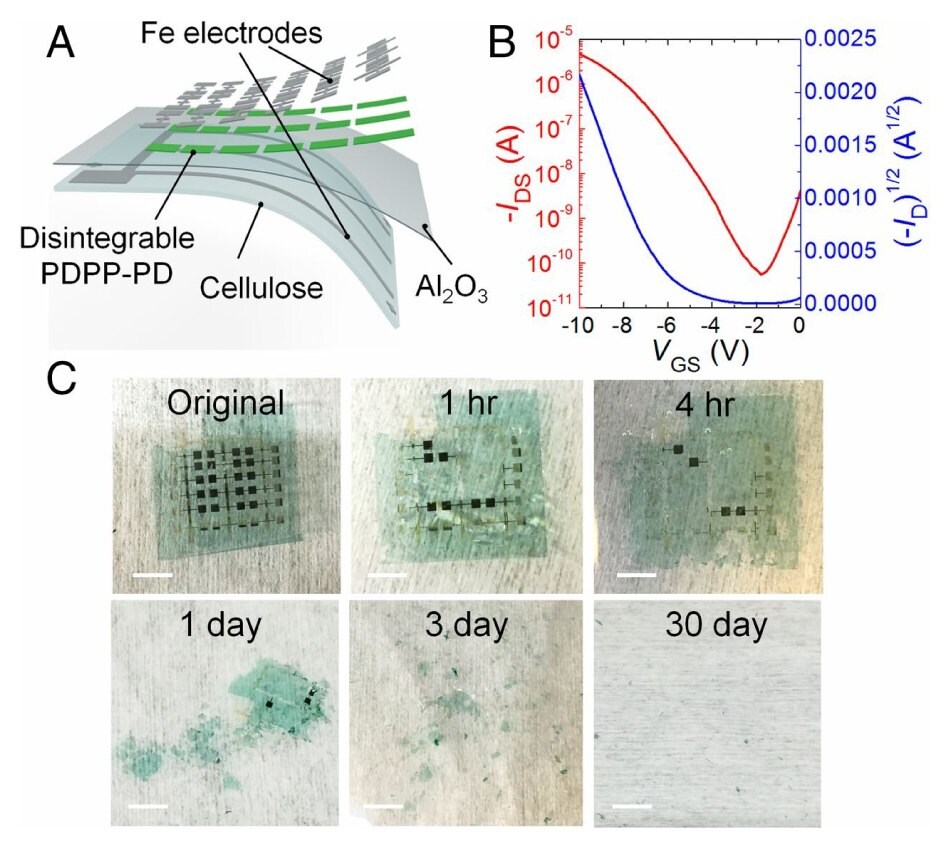

OTFTs often use thin metallic electrodes, which can have some drawbacks for “green” electronics. Metals are non-renewable, non-biodegradable, and challenging to extract from devices for recycling. Vacuum thermal evaporation, a common deposition method, is also very energy intensive due to the elevated temperatures and high vacuum required. Nevertheless, choosing the right metals can be beneficial. For example, fully disintegrable OTFTs have been achieved using thin iron electrodes, which rapidly disintegrate under acidic conditions (Figure 3).9

Figure 3.Fully disintegrable OTFTs using iron source, drain, and gate electrodes. Cellulose is used as the substrate, Al2O3 as the dielectric, and poly(diketopyrrolopyrrole-p-phenylenediamine) (PDPP-PD) as the semiconductor. A) Device structure. B) Transfer characteristics. C) Photographs showing stages of decomposition (scale bars indicate 5 mm). Reproduced with permission from reference 9, copyright 2017 National Academy of Sciences.

Conductive polymers, particularly poly(3,4-ethylenedioxythiophene) doped with poly(styrenesulfonate) (PEDOT:PSS, like Cat. Nos. 900208, 900181, 768650, 483095), have been widely used in OTFTs in place of metallic electrodes, and offer some significant advantages. PEDOT:PSS is well known to be biocompatible and can be printed with minimal waste from water dispersions, avoiding hazards associated with toxic solvents.10 Many commercial PEDOT:PSS formulations include toxic additives to enhance conductivity and stability, though concentrations of these additives are low and toxins negligible in the final films.10 It is also notable that PEDOT:PSS and other conducting polymers are not considered biodegradable. The π-conjugated structure that is fundamental to the conductivity of these polymers makes them inert, thus, resistant to degradation.11 Efforts to improve the biodegradability of conducting polymers often involve blending conductive and intrinsically biodegradable polymers. The principle is that the biodegradable polymers will serve as a matrix for the conductive polymers and when degraded, will allow the conductive polymers to disperse. For example, non-degradable polypyrrole (PPy, Cat. Nos. 577065, 530573) can be combined with PLA or poly(lactic-co-glycolic acid) (PLGA) to form partially degradable blends. Alternatively, researchers have simply used much shorter conductive chains (oligomers), such as oligomers of aniline or thiophene, which are degraded more readily than polymers. A further possibility is to construct co-polymers with alternating biodegradable and conducting segments. The breakdown of the biodegradable segments breaks the polymers into smaller pieces that organisms can more readily process. For example, co-polymers can be formed using biodegradable chitosan and aniline pentamers (i.e., strings of five aniline units).11 Such approaches have had minimal use in OTFT electrodes to date.

Insulators and Electrolytes

Substantial work has been done towards finding environmentally friendly and naturally sourced dielectric materials for OTFTs. We will discuss a few interesting examples.

Polypropylene carbonate (PPC) is a material synthesized from carbon dioxide (CO2) and propylene oxide and is often considered to be a more environmentally friendly polymer. PPC sequesters captured CO2 and is synthesized without using organic solvents or producing organic waste. It is also enzymatically biodegradable. PPC has been demonstrated as an effective dielectric for both p-type and n-type OFETs, as well as serving as a flexible substrate.12 While promising, it should be noted that PPC is not wholistically “green.” The precursor, propylene oxide, is a toxin and carcinogen originating from non-renewable petroleum.13 For these reasons, many researchers have preferred naturally sourced dielectric materials.

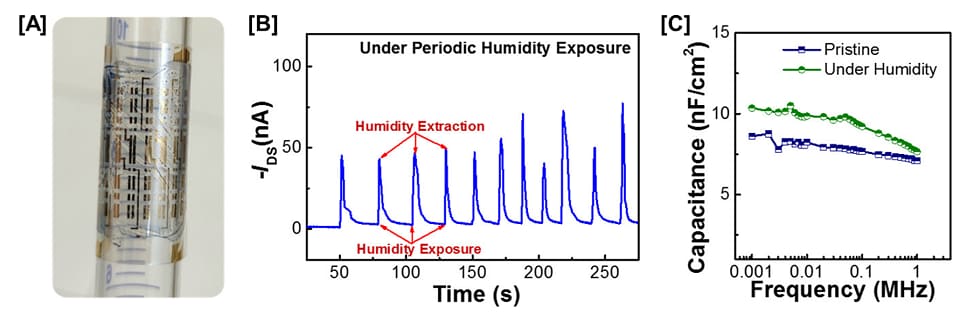

One promising natural dielectric is almond gum, a polysaccharide produced by almond trees. Almond gum is nontoxic, biodegradable, and water soluble. In a 2020 study, the authors used fresh almond gum with minimal processing. The material was dissolved in distilled water and coated via spray pyrolysis. OFETs using almond gum dielectric layers exhibited good, low-voltage (<3 V) characteristics.14 Another natural and biodegradable dielectric is gelatine (Cat. No. 1.04078), a protein extracted from the bones, skin, and other tissues of animals used in the livestock industry. In one study, gelatine films were spin-coated from an aqueous solution and used in flexible OFETs. The OFETs were responsive to changes in humidity, where device performance improved with greater moisture content, owing to an increase in capacitance due to the mobilization of ions in the gelatine layers (Figure 4).15

Figure 4.A) OFET array with gelatine dielectric, wrapped around a glass tube to show its flexibility. B) The drain-source current of the gelatine OFET under periodic exposure to humid air. C) Exposure to humidity increases the capacitance of the gelatine layer. Reproduced with permission from V. Raghuwanshi et al. ACS Appl. Electron. Mater. 2020, 2, 3373-3379. Copyright 2020 American Chemical Society.

A recent development is the use of crosslinked dextran (Cat. No. 31430), a natural polymer that fungi can decompose. The authors of this study note that many previously reported biodegradable dielectrics, including cellulose (Cat. No. 433837) and chitosan (Cat. Nos. 900342 and 900341), are polar and hydrophilic, meaning they are affected by ambient moisture and induce charge trapping. While such properties are potentially useful in devices such as humidity sensors, as seen above, this behavior is usually unwanted. The cross-linking of dextran reduces its polar hydroxyl groups, enabling stable, high-performance OFETs. The full device, where the dextran dielectric doubles as a substrate, was observed to disappear within 67 hours of contact with fungi grown on decomposing peaches. The non-biodegradable components (including gold electrodes) were broken up and dispersed.16

Not all OTFTs rely on conventional dielectric layers. OECTs (organic electrochemical transistors) and electrolyte gated OFETs (EGOFETs), which are widely used as sensors, replace the dielectric with electrolytes that allow low-voltage operation. Electrolytes can be as simple as salt water. In some sensing applications, the fluid under analysis serves as the electrolyte. In these cases, the environmental impact of the electrolyte is negligible. One limitation of liquid electrolytes is that they require additional structures to contain or encapsulate them, which can be bulky and add to fabrication complexity. To achieve very thin, self-contained EGOFETs and OECTs (organic electrochemical transistors) with no risk of leaking or spilling, solid-state electrolytes are sometimes preferable. However, many reported solid electrolytes are not biodegradable or biocompatible. In one recent report, a solid, biodegradable electrolyte composed of Levan polysaccharide and a choline-based ionic liquid was used in a hybrid EGOFET/OECT device.17 The choline-based ionic liquid was formed by reacting choline with malic acid, resulting in a liquid with choline cations and malate anions. After mixing with an aqueous solution of the Levan polysaccharide, the material was cast as a freestanding film and used as both substrate and dielectric. Metal electrodes (chromium and gold) were thermally evaporated and the biocompatible semiconductor poly[3-(5-carboxypentyl)thiophene-2,5-diyl] (P3CPT) was spin-coated onto polydimethylsiloxane (PDMS, Cat. Nos. 482145, 480282, 433012, 481696) and subsequently transferred to the electrolyte. Biocompatibility was demonstrated by subcutaneously implanting the device into rats. The device was decomposed within seven days in vivo. The transistors successfully measured electrocardiogram signals on human skin and rat hearts.17

Semiconductors

The active layer of an OTFT, the organic semiconductor, has been comparatively overlooked in efforts to find greener materials for OTFTs. Many of the most common organic semiconductors in use are biocompatible but show limited biodegradability and rely on toxic solvents for solution processing. Nevertheless, some good progress has been made.

Indigo is a natural dye that has long been used as food colorings and textile dyes, exhibiting low toxicity and good biodegradability.18 Indigo derivatives can be synthesized for optimized semiconductor characteristics; many variations have been tested in OTFTs. In one paper, OFETs were fabricated using a variety of indigo derivatives, including 6,6’-dichloroindigo and 5,5’,6,6’-tetrafluoroindigo. Depending on the added functional groups, these displayed a range of n-type and ambipolar charge transport characteristics. However, the indigo films were deposited via vacuum thermal evaporation due to their poor solubility. Another limitation of these organic semiconductors was their poor stability in air.18

A decomposable conjugated polymer was synthesized from the naturally derived and degradable monomer diketopyrrolopyrrole (DPP) in another study. The monomers were linked with imine bonds, which break down in mild acid.9 Biocompatibility of the new polymer was demonstrated with in vitro cell culture tests. Transistors made using this material exhibited “nearly ideal” transistor characteristics, with good hole mobilities, on/off ratios, and air stability. Flexible devices were made using this polymer, combining cellulose substrates with dissolvable iron electrodes, as mentioned earlier, to create fully degradable devices (Figure 2).9

Recognition Elements

The components reviewed thus far apply to OTFTs in general. In OTFT sensors, a recognition element is also typically required to facilitate selective interaction with an intended ion or molecule. As with all other transistor components, environmental impacts relating to the recognition element must be considered.

In many cases, the recognition element is a naturally occurring molecule, such as an enzyme or antigen, that is immobilized onto an active surface of the transistor, such as the gate electrode. For example, an OECT sensor for COVID-19 antibodies has been demonstrated.19 A person infected with SARS-CoV-2 will produce antibodies that bind to a specific antigen associated with the virus, such as the spike protein. The presence of antibodies indicates past or present infection. To detect antibodies using an OECT, spike proteins from the virus were chemically bound to a self assembled monolayer of mercaptoacetic acid on the gold gate electrode of the transistor. The positive charge of the antibodies causes a shift in the effective gate voltage of the device.19 In this case, the antigen itself is a natural protein that will degrade under normal conditions, posing no environmental threat. However, further investigation would be needed to assess the monolayer and electrode.

To achieve ion selectivity in OTFTs, it is common to use an ion-selective membrane, which is also widely used in potentiometric ion-selective electrodes. The membrane is typically made using plasticized polyvinyl chloride (PVC, Cat. Nos. 81388, 81392) embedded with ionophores, which selectively bind with a specific ion, changing the membrane potential. More environmentally friendly alternatives to PVC have been explored, including PLA.20 PLA is a sustainable, plant-derived thermoplastic used as 3D printing feedstock that is considered biodegradable under certain conditions. To make a PLA membrane, plasticized PLA was combined with an ionophore and extruded into a 3D printing filament. The membranes could then be printed into the desired shape using a conventional, consumer-grade 3D printer. The 3D printed membranes were demonstrated in an electrochemical cell to detect Hg2+ concentration in water.20 While this approach to producing environmentally friendly ion-selective membranes would be straightforwardly transferrable to OTFT sensors, this has not yet been reported.

Conclusions

In this brief review, we have seen examples of how a careful choice of materials can significantly reduce the environmental impact of each principal component of OTFT sensors. A considerable amount of essential and innovative work has already been done, but progress has yet to be uniform in every area. It is also clear that many of these developments have been demonstrated in isolation. Few reports show complete devices that are wholistically ecological, non-toxic, and safely degradable for each component. Further work is therefore needed to integrate the many existing insights together into fully eco-friendly OTFT sensors. In attempting this, an ongoing challenge will be to achieve the device performances needed to compete with current state-of-the-art devices. We hope this will drive further innovation. Finally, we have observed several places where a proposed material, while promising great environmental benefits in one aspect, may have notable weaknesses in other areas. Such work should still be encouraged. Even partially “green” electronics may have tangible benefits as we work toward a sustainable future. Nevertheless, caution and skepticism are warranted with claims of environmental friendliness.

References

To continue reading please sign in or create an account.

Don't Have An Account?