Active Pharmaceutical Ingredient (API) Stability in Solid Dose Formulation

The Impact of API Instability

Poor API stability in solid dose drug development can lead to serious consequences including:

- A decline in the API dosage or generation of toxic degradation products affecting efficacy and patient safety

- A lack of regulatory acceptance of the drug

- A reduction in shelf-life

- An increase of the complexity and cost of drug storage requirements

Read more about

- Causes of API Instability

- Excipients can Negatively Affect API Stability

- Case Studies

- Conclusion

- Related Products

Causes of API Instability

Several factors may lead to an API becoming unstable and are listed below. The effect differs among APIs and depends on their chemical nature and other characteristics.

- Exposure to heat and/or changes in temperature

- Exposure to moisture

- Oxidation

- High or low pH or changes in pH

- Biological contamination

- Exposure to light

- Interaction with other formulation components

Excipients can Negatively Affect API Stability

Because excipients can both help to prevent API instabilities and induce them, selection of an appropriate excipient is essential. Examples of how excipients can induce API instabilities include direct interaction/reactivity with other excipients, hygroscopicity of the excipient, and impurities in the excipient. Process-related factors such as compression and granulation tableting methods can also induce instability of the API. Finally, environmental factors such as oxidation can lead to API instability.

These issues and how they can be addressed with selection of the appropriate excipient are described below.

Direct Interaction/Reactivity

An excipient can prove to be incompatible with the formulation and/or the API. They may interact and/or react with each other or with the API in an undesirable manner. As an example, lactose is commonly used in solid dose formulations, and yet it can interact with the API, primarily with amine groups via the Maillard reaction. Similarly, magnesium stearate is often used as a lubricant but is incompatible with acidic APIs such as acetylsalicylic acid and most alkaloid APIs. A solution for this is to avoid excipient/API combinations that are obviously incompatible as far as the chemistry is concerned.

Hygroscopicity of the Excipient

The water content of commonly used fillers in solid dose formulations can vary widely. For example, a water content as high as 15% is still within compendial specifications for starch, while only 0.3% is applicable for mannitol. These ranges derive from the fact that different measurement methods are applied, and different parameters are specified such as moisture content or loss on drying.

Formulators may hesitate to use an excipient because of its hygroscopicity, even though it may only be relevant when specific conditions are present, and not in all cases. For example, sorbitol is generally regarded as highly hygroscopic but is only hygroscopic in an environment with a relative humidity of 65% or more. Such environmental conditions can be controlled during the production process and the packaging type and material helps to prevent any effects that may otherwise occur during storage of the final formulation.

Figure 1 compares the water absorption of commonly used fillers in solid formulations such as mannitol, microcrystalline cellulose (MCC), and sorbitol.

Figure 1.Dynamic vapor sorption (DVS) results of spray-dried beta-polymorphic mannitol, MCC and spray dried and crystallized sorbitol.

Impurities

A range of impurities can be found in excipients and formulators should use care when selecting their source. Excipients may for example include water, reducing sugars such as glucose, aldehydes, free radicals, and peroxides, all of which may promote API instability.

It is therefore critical to choose an excipient with a sufficiently low specified level and confirmed low variation from batch to batch.

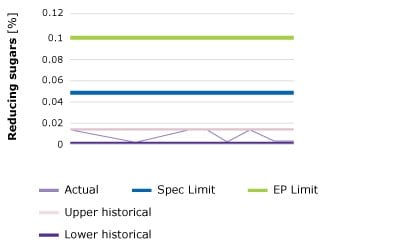

Figure 2 shows the minimal batch-to-batch variation of reducing sugar levels in Parteck® M excipient, a mannitol produced with reducing sugar levels below that of pharmacopeial limits.

Figure 2.Batch-to-batch variation of reducing sugar levels in particle- engineered Parteck® M mannitol, showing a level of reducing sugars well below pharmacopeial and specified levels.

Oxidation

The risk of oxidation of an API can be prevented with the use of different coatings or packaging types and materials as these help protect it from environmental conditions and exposure to substances such as oxygen. While excipients do not typically react directly with the API, their impurities may react. Excipients may contain peroxides which may affect oxidation. For example, povidone and crospovidone are often included in excipient systems for orally disintegrating tablets (ODTs) and are a source of peroxides.

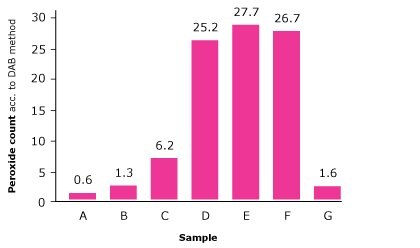

Figure 3 shows that the peroxide levels of ODT excipient systems C-F, which contain povidone and crospovidone, are up to 46 times higher than those of ODT excipient systems without povidone and crospovidone (A, B, and G).

In general, peroxide levels must be low for all excipients; povidone and crospovidone, in particular, should be avoided completely because these polyvinyl pyrrolidone (PVP)-based excipients are known to contain residual peroxide impurities and the levels can vary among suppliers.

Consequently, for oxidation-prone APIs special care should be taken to select excipients with low levels of peroxides such as

Parteck® ODT mannitol-based ODT excipient system. Given the risk, the use of povidone and crospovidone should be avoided.

Figure 3.Peroxides levels in commercially available ready-to-use ODT excipient systems.

- Mannitol, croscarmellose sodium

- Lactose, starch

- Mannitol, crospovidone, povidone, polyvinyl acetate

- Mannitol, xylitol, microcrystalline cellulose (MCC), crospovidone, calcium dihydrogen phosphate dihydrate

- Mannitol, xylitol, MCC, crospovidone, Mg Al silicate

- Mannitol, fructose, MCC, solicon dioxide, crospovidone

- Mannitol, starch

Compression

The compression force used in solid dose formation can affect API stability in three ways:

- The pressure exerted in the tableting process can create localized temperatures of more than 160°C within a tablet and lead to the melting of an excipient. Degradation products may be observed after compression of temperature-sensitive APIs that had been stable in the powder mixture.

- Certain polymorphic forms of an API that are, for example, intended to achieve better bioavailability can be temperature sensitive. A temperature increase during the tableting process can result in a partial change of the API’s polymorphic form and alter the final formulation performance.

- The shear force that is applied in the tableting process may break apart large molecules or the coating of API particles. Coated API particles may have been formulated to mask a bitter taste, modifying release kinetics or improving API stability. Application of shear force results in particle break-up, compromising the intent of the coating.

Figure 4B shows the particle-engineered Parteck® M excipient has a larger surface area than conventional direct compressible mannitol (Figure 4A). Parteck® M mannitol has good compressibility which makes it well suited for direct compression and especially well-suited for high-dose formulation as it can compensate for poor compressibility/flowability of the API. In the case of a low dose formulation, adsorption to the excipient’s large surface reduces the risk of de-mixing during the process and ensures good content uniformity.

Figure 4.SEM images comparing the particle structures of conventional directly compressible mannitol (A) and particle engineered Parteck® M mannitol (B).

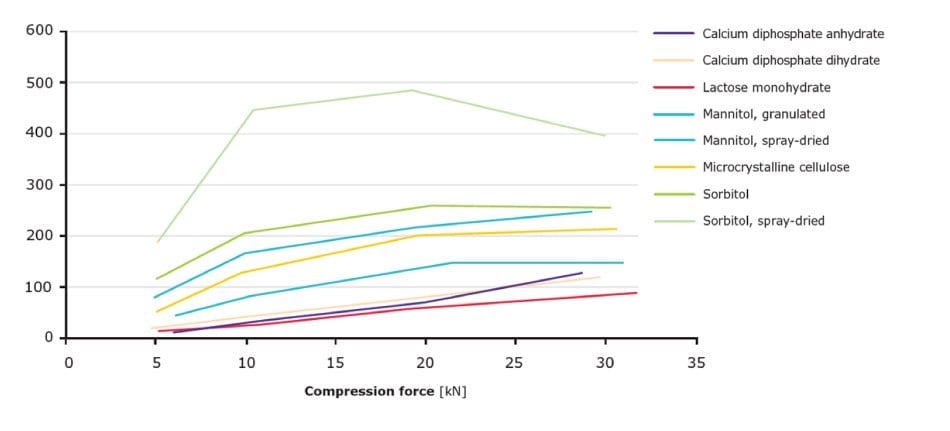

Figure 5 compares the compressibility of different directly compressible fillers. The upper two curves represent sorbitol; the higher curve is the spray-dried form Parteck® SI sorbitol, and the lower curve is the crystallized form. The difference in performance between these two forms is explained by the larger surface area of sorbitol in its spray-dried form. The larger surface area leads to greater compressibility and increased tablet hardness.

It is also important to note that sorbitol is much more compressible than lactose, phosphates, and other alternatives. With a melting temperature of 95 °C, sorbitol melts to a certain degree during the tableting process. When the increased temperature dissipates, recrystallization of slightly molten particles creates a much stronger binding when compared with the mechanical binding of particles within MCC, for example. This binding process leads to the good compressibility of sorbitol.

Figure 5.Comparison of tablet hardness manufactured at different compression forces using a variety of directly compressible fillers.

Granulation

The granulation process can also affect API stability and is the reason why direct compression is often preferred to wet granulation for sensitive APIs which require water and heat. These advantages can outweigh the shortcomings of direct compression in relation to content uniformity, compressibility, and flow in some instances.

Content uniformity is important because, in a statistical mixture where the API and excipient particle sizes differ significantly, segregation can occur.

Figure 6 illustrates an alternative solution – an ordered mixture – in which API particles, typically micronized, are adsorbed on the surface of the excipient particle. The excipient particle in Figure 6A has a smaller, smoother surface area with limited regions where the API is located in an adsorbed form. Figure 6B shows a mannitol with a larger, more structured surface area which more easily adsorbs the API.

Figure 6.The excipient particle in Figure 6A has a smaller, smoother surface area with limited regions where the API is located in an adsorbed form.

Figure 6B shows a mannitol with a larger, more structured surface area which more easily adsorbs the API

Example 1: Case Study with a low-dose, moisture-sensitive API

In formulations with a very low dose API, the API must be effectively distributed to ensure good content uniformity of the final solid dosage forms. Direct compression would not typically be selected in this instance, due to concerns about the ability to maintain content uniformity within target parameters.

However, in the present case study, the API is moisture sensitive, and as such, the traditional wet granulation process using water and heat is unsuitable.

A low-dose, water-sensitive API was formulated according to the composition shown in Table 1. The API was premixed with 15% of Parteck® M 200 excipient, then diluted with the rest of the formulation. The homogeneous blend was tableted on a high-speed rotary tablet press (7 mm punch, 9 kN) at speeds of 40,000 tablets/h and 80,000 tablets/h.

Changing the speed of the tableting process did not result in significant deviations in tablet weight and hardness due to the good flow and compressibility of Parteck® M excipient, showing that it is ideal for high-throughput production on fast rotary presses (Table 2).

Example 2: Highly sensitive API atorvastatin

Atorvastatin is an API that is sensitive to heat, moisture, oxidation, light, and acids and is unstable in its amorphous form. Several strategies can be employed to overcome these challenges:

- To address the moisture and heat sensitivity, direct compression should be used instead of wet granulation.

- Low compression force is required to negate heat sensitivity and amorphous instability.

- To prevent oxidation, the use of peroxides contained in excipients like povidone or crospovidone should be avoided.

- Acid sensitivity can be addressed via the addition of an alkalizer such as meglumine or calcium carbonate.

- Light sensitivity is not a significant issue when choosing appropriate excipients because most of the API material is hidden within the tablet or can be addressed by coating the tablet or using appropriate packaging.

Overall, one possible approach for an atorvastatin formulation could involve the use of a mannitol with a low moisture content, together with an alkalizer in a low-force direct compression process.

Conclusion

Excipients should not be considered inert ingredients in solid dosage formulations as they can either improve API stability or induce instabilities. Addressing API instability using a simple strategy can minimize the potential for component interactions. In addition, when choosing a formulation technology, possible API instabilities from exposure to heat and/or moisture must be considered.

Overall, direct compression, used in conjunction with excipients that exhibit low moisture content and a low impurity profile, can be the best approach to solid-dose drug production, especially if formulating APIs prone to instabilities.

Download our whitepaper to learn more about how excipients can affect API instability.

Learn more about formulation development and guidelines for these manufacturing processes and suitable excipients in our Formulation Handbook.

Related Products

如要继续阅读,请登录或创建帐户。

暂无帐户?