Scalable Tangential Flow Filtration (TFF) for Downstream Processing of Viral Vectors for Gene Therapy and Vaccine Production

Section Overview

- Use of Tangential Flow Filtration During Viral Vector Manufacturing

- Best Practices when Designing a TFF Step for Viral Vector Manufacturing

- Types of TFF Membranes and Filter Formats used in Viral Vector Purification

- TFF Operating Control Strategies and Scalability for Viral Vector Process Development

- Comparison of Pellicon® Capsules and Hollow Fibers for TFF in Viral Gene Therapy Manufacturing

- Related Resources

- Related Products

Use of Tangential Flow Filtration During Viral Vector Manufacturing

The production of viral vectors is a critical step in gene therapy and vaccine manufacturing. Success depends on using the right technologies to ensure an optimized, efficient, and predictable process. An essential technology used in downstream processing of viral vectors is tangential flow filtration (TFF).

During viral vector manufacturing, the TFF step is used for two important purposes:

- Volume reduction and diafiltration prior to a capture chromatography step

- Final concentration and exchange to formulation buffer prior to the final sterile filtration

Ultimately, TFF ensures the target concentration of the viral vector is reached, and the final product is in the desired drug substance matrix or buffer.

Development and optimization of TFF steps in downstream processing requires consideration of several factors.

Best Practices when Designing a TFF Step for Viral Vector Manufacturing

Designing a TFF step begins with identifying the objective, whether it is to achieve a targeted product concentration to eliminate some downstream processing bottlenecks, or to transfer a formulation into a specific buffer and then concentrate it at the end of the purification process. It is critical to choose a system design and a device format that is scalable; in addition, the systems need to be characterized for at-scale performance with the appropriate turndown ratios to achieve the desired yields and capacities at the full scale.

An important consideration when using closed processing is that the system and the device should be designed for this approach. It is particularly helpful to have process performance and recovery data available for at-scale systems and at-scale devices.

The size and the isoelectric point of the target molecule should also be known as well as how key process variables such as temperature, shear, and mixing affect the stability of the modality. It should also be known how the modality interacts with the materials of construction, whether the membrane is polyethersulfone (PES)-based or regenerated cellulose-based. Typically, regenerated cellulose is preferred for applications requiring low molecule binding; however, the type of membrane and its interaction with the modality needs to be experimentally verified. A final consideration is how stable the modality is in a particular buffer matrix.

Types of TFF Membranes and Filter Formats used in Viral Vector Purification

Different types of membranes and filter formats are available for TFF. Membranes made of PES or regenerated cellulose with a molecular weight cut-off of 30, 100 or 300 kDa are generally recommended for viral vector production. The two most common filter formats are flat sheet cassettes or capsules and hollow fibers.

Hollow fibers, traditionally used for industrial and biomedical separations, have been adopted for many biopharmaceutical applications. They are available with modified PES and mixed cellulose ester lumens. A hollow fiber filter can be selected based on lumen number, diameter, and length. Flat sheet cassettes, available with both modified PES and regenerated cellulose membranes, are specifically designed for biopharmaceutical applications. They are very robust and offer efficient process performance and linear scalability in a compact format.

Figure 1.A first-of-its kind spiral wound Pellicon® Capsule format was engineered to provide high performance and linear scalability in a plug-and-play design and is particularly well-suited for use in viral vector production. Membrane pore sizes include 100 kDA and 300 kDa.

TFF Operating Control Strategies and Scalability for Viral Vector Process Development

Permeate-control TFF systems are typically used for microfiltration (MF) applications in which highly permeable membranes can lead to excessively high fluxes that degrade or destabilize performance. For tighter ultrafiltration (UF) membrane applications, such as 30 kDa for antibody retention, transmembrane pressure (TMP)-control systems are used as an alternative. In contrast, membrane cutoffs typically used in viral vector manufacturing, such as adeno-associated virus (AAV) and lentivirus (LV), are 100 and 300 kDa. The openness of these membranes falls between the tighter UF and more open MF applications.

A study was performed to evaluate both TMP and permeate control strategies during the post-clarification / pre-capture TFF step in a viral vector manufacturing workflow. The Pellicon® Capsule was used in the experiments along with scale-down Pellicon® XL 50 cassettes with 100 and 300 kDa Ultracel® membrane.

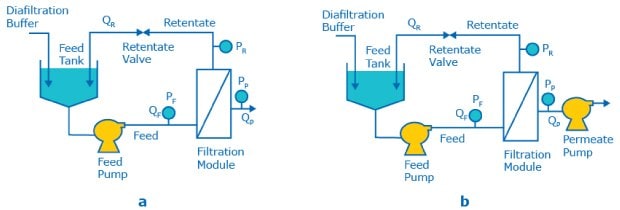

For the TMP-control operation, a feed pump was used and there was free flow of permeate (Figure 1). A two-pump TFF system was used for the permeate-control operation, which included a feed pump and a permeate pump to restrict and control flow of the permeate.

Figure 2.Schematic of TFF systems used in this study: TMP control (a) and permeate control with permeate pump (b).

Initial experiments were performed to characterize permeate flux of the TFF filters for both control strategies. Following this, ultrafiltration/diafiltration (UF/DF) process simulations were run to evaluate average flux, processing time, TMP, virus yield, and impurity reduction (Table 1). The process simulation goal was to concentrate four-fold (4x) in batch mode, diafilter with five diavolumes (5 DV) of HEPES buffer at constant volume, and then concentrate two-and-a-half-fold (2.5x) in batch mode for an overall volumetric concentration factor (VCF) of 10x.

The complete set of methods and experimental results can be found in the application note entitled: Evaluation of TFF Operating Control Strategies and Scalability for Viral Vector Process Development

Comparison of TFF Control Strategies

TMP-control systems are relatively simple, the user only needs to set feed flow and the retentate valve to give a target TMP. When the operating point is set near the plateau, the flux will be close to the maximum at every point during the UF/DF process, naturally decreasing with concentration. This approach can give the shortest process time due to higher average flux. However, if the process becomes unstable or performance is too low while using TMP control, restriction of permeate flow may be needed.

Permeate-control systems can restrict permeate flow to operate well below the minimum flux of TMP-control systems and reduce polarization at the membrane, which can improve performance such as impurity reduction. However, permeate-control systems require additional control elements beyond those used in TMP-control systems (permeate pump or control valve) and could result in an exponential rise in TMP at the critical flux, potentially preventing run completion due to feed pressure or TMP limitations.

In this study, based on 300 kDa membrane comparisons with Pellicon® Capsule and Pellicon® XL 50 cassette, TMP-control operation demonstrated a flux (or time) advantage as high as two-fold, which can reduce the required membrane area in half. Permeate-control operation demonstrated a higher impurity removal advantage. Results for virus yield were mixed. The yield was similar for AAV2 when using both control strategies, but yield was generally higher for the permeate-control model studies with bacteriophage.

Scaling within Pellicon® Capsule and Cassette Families

Scaling of capsules and cassettes was demonstrated by comparing flux, TMP profile, yield, and impurity reduction using a virus model feed and AAV2. The family of Pellicon® TFF filters enables linear scaling over a wide range of feed batch sizes. Table 2 shows an example of how TFF batches up to 2,000 liters can be handled with single-use Pellicon® Capsules. If scaling to larger, multi-use batches is required, switching to Pellicon® 2 cassettes with the same membrane and screen combination can be done seamlessly.

Comparison of Pellicon® Capsules and Hollow Fibers for TFF in Viral Gene Therapy Manufacturing

The following study evaluated filter performance during the TFF1 step while using a virus model feed. Pellicon® Capsules and its scale-down filter, Pellicon® XL 50 cassettes, were evaluated in this study and compared with two hollow fiber modules, HF-A (0.5 mm/60 cm) and HF-B (0.5 mm/20 cm), in terms of performance.

The complete set of methods and experimental results can be found in the application note entitled: Pellicon® Capsules versus Hollow Fibers for Ultrafiltration/Diafiltration (UF/DF) in Viral Gene Therapy Manufacturing

Sizing Scenarios and Process Impact Analysis

The results of a 300 kDa permeate-control process simulation were applied to build two theoretical sizing scenarios using Pellicon® Capsule and the hollow fibers:

- Scenario 1 assumes the same loading is used for all filters. This scenario compares run times and maximum possible VCF for a 100 L batch at 35 L/m2 loading.

- Scenario 2 restricts the time required to complete the TFF process. This scenario compares filtration area required and maximum possible VCF for processing a 1000 L batch in 4 hours, which requires variable loading.

Results from Scenario 1 are shown in Table 3. When using the same loading (35 L/m2), the Pellicon® Capsule runs 2.9x faster than hollow fiber HF-A at the same normalized crossflow rate. The capsule is still 1.7x faster even when hollow fiber HF-B uses triple the capsule crossflow rate. Although HF-B was able to save some time compared to HF-A, the higher crossflow rate reduces the hollow fiber system’s maximum possible VCF by a factor of ~4x.

Scenario 2 results are shown in Table 4. To obtain the same process time (4 hours), the Pellicon® Capsule only required 35% of the filtration area and 37% of the feed flow of the hollow fiber module when the filters operate at the same crossflow rate—i.e., compared to the HF-A case. If the crossflow rate of the hollow fiber is tripled to increase its flux (HF-B case), the capsule required only 58% of the hollow fiber filtration area and 21% of its feed flow. It should also be noted that the higher feed flow of the hollow fiber system reduces the maximum possible VCF ~4x.

Overall, the results of the study showed that hollow fiber modules give lower flux at a given shear and as a result, a much higher membrane area or processing time is required compared to Pellicon® Capsules. While crossflow rates of hollow fibers were increased to achieve a higher production rate, flux remained lower than Pellicon® Capsules and the resulting system may be limited in achieving high concentration targets.

In contrast, Pellicon® Capsules achieved higher and more stable flux than hollow fibers, resulting in a more efficient TFF process while delivering a comparable virus yield. The resulting system is also smaller, which enables higher concentration targets.

Experience the benefits of Pellicon® Capsules for yourself—click here to request your free sample.

Related Resources

- Application Note: Scalable Purification of Plasmid DNA: Strategies and Considerations for Vaccine and Gene Therapy Manufacturing

This application note describes an end-to-end platform consisting of single-use technologies and validation and testing services for pDNA manufacturing.

- Technical Brief: Evaluation of TFF Operating Control Strategies and Scalability for Viral Vector Process Development

In this technical brief, we discuss use of our new single-use technology for tangential flow filtration (TFF) of viral vectors during the evaluation of two TFF operating control strategies.

- Application Note: Pellicon® Capsules versus Hollow Fibers for Ultrafiltration/Diafiltration (UF/DF) in Viral Gene Therapy Manufacturing

This application note discusses methodology and experimental results in the performance evaluation of Pellicon® Capsules versus hollow fibers for UF/DF of viral vectors and describes the impact of either filter type on a TFF process.

- Tech Note: Tangential Flow Filtration (UF/DF) of Plasmid DNA

Pellicon® 2 cassette with Biomax® 100 kDa C-screen/ V-screen can be used for concentration and diafiltration with high loading and yield.

- Product Overview: Ultrafiltration/Diafiltration (UF/DF) of Adeno-Associated Viruses (AAV) with Pellicon® Capsules and Pellicon® XL 50 Cassettes

Part of the linearly scalable Pellicon® family of TFF filters, single-use Pellicon® Capsules and scale-down Pellicon® XL 50 cassettes provide reliability and reproducibility at any stage of your AAV process, from development to manufacturing.

- Podcast Transcript: Interview - Shear ignorance? Think again: breaking the perception of shear within viral vector manufacturing

In this episode, Ratish Krishnan and Akshat Gupta discuss best practices – and common misconceptions – when establishing process conditions and utilizing different TFF device formats.

To continue reading please sign in or create an account.

Don't Have An Account?