Zirconia (ZrO2) Nanocrystals and Their Nanocomposite Applications

Introduction

Technology advances have put high demands on optical material development in recent years to keep pace with improvements in electronic devices, from displays and sensors to optical elements. Nanomaterials have been of great interest in manufacturing and electronics, but many initially promising nanotechnology techniques have not been as easy to scale up and implement as broadly as expected. However, the emergence of nanocrystals has significantly benefited the commercial scalability of nanotechnology applications.

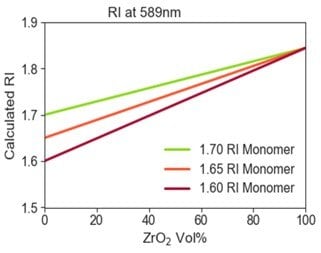

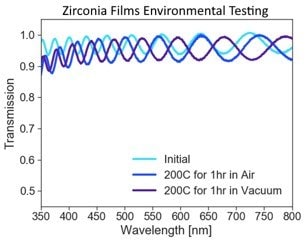

ZrO2 nanocrystals have a 5 nm core that is capped using capping agents for a final average particle size of 10 nm, as shown in Figure 1. Using 10nm scale ZrO2 nanoparticles, a combination of organic-inorganic nanocomposites can be made to produce clear dispersions and films. The combined functional and mechanical properties (Table 1) of these nanoparticles can add value in many engineering disciplines and applications. Organic polymer materials are beneficial for their low molecular weight, flexibility, and manufacturing processability; inorganic materials, such as ZrO2, are desirable for their hardness, strength, transparency, and high refractive index (RI) values, as shown in Figure 2. Organic-inorganic nanocomposites can be made to have high RI values and high transparency while also being processable in commonly used manufacturing processes, as shown in Figure 3.

Figure 1. Core particle size of ZrO2 nanocrystals by TEM (left) and particle size distribution curves (right) for ZrO2 nanoparticles by way of dynamic light scattering (DLS)

Figure 2.Potential refractive index of formulated ZrO2

Figure 3.Transparency and environmental testing of zirconia films.

Applications

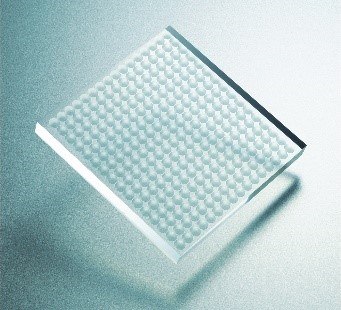

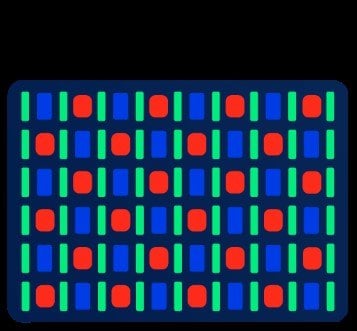

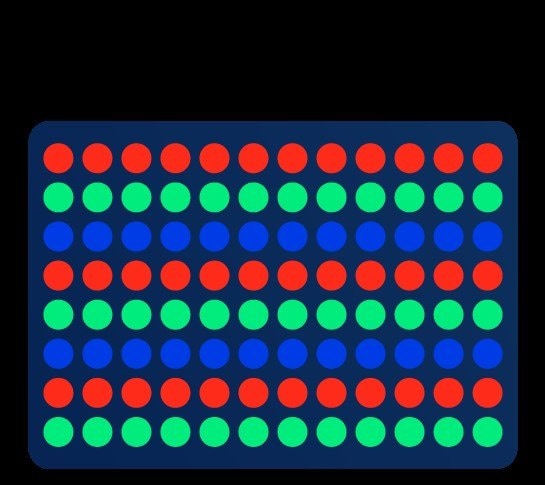

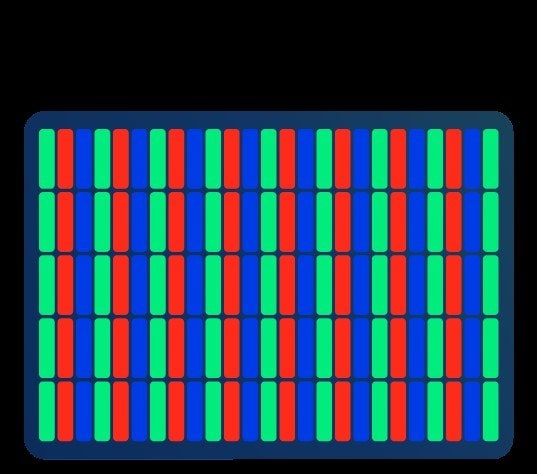

Target applications for the ZrO2 include augmented reality (AR)/virtual reality (VR), optical devices such as diffractive optical elements, wafer-level optics, sensors, and micro-lens arrays, and various display technologies including organic light-emitting diodes (OLEDs), quantum dots, and mini and micro light-emitting diodes (LEDs), as shown in Figure 4.

AR/VR Waveguides

Diffractive Optical Elements

Micro Lens Arrays

Wafer Level Optics

CMOS Sensors

OLED Displays

MicroLED Displays

Quantum Dot Displays

Figure 4. Common applications areas for ZrO2 nanocrystals

Processing

For most applications, the ZrO2 nanocrystals are combined with resins to create an organic-inorganic nanocomposite material as the final product. Two common solvents available for ZrO2 nanodispersions, propylene glycol methyl ether acetate (PGA) and ethyl acetate (ETA), offer high and low boiling point options for formulations. PGA-based dispersions allow users to combine desired soluble monomers, photoinitiators, and other additives to create solvent-containing formulations. Deposition of solvent-containing and solvent-free formulations is possible using spin-coating, inkjet-printing, and slot die-coating. For PGA-based formulations, film deposition is followed by baking steps for PGA removal. ETA-based dispersions are conducive to lower temperature film-baking steps or solvent removal like rotary evaporation (Rotovap) to make solvent-free formulations with no film baking steps. Using a stable product with and without solvent allows the user to adjust the material composition to match optimal factory processing steps.

5 nm (core) ZrO2 Nanoparticle Materials Available

919985 and 915491 are ZrO2 nanocrystals that possess a non-functional, highly dispersible capping agent with a proven history of compatibility in many solvents and monomer systems. 919985 and 915491 are often the first nanocrystal chosen for customers to establish compatibility and clarity.

916005 and 9016269 represent ZrO2 nanocrystals that also possess a non-functional, highly dispersible capping agent with different capping chemistry than 919985 are 915491. 916005 and 9016269 are chosen by customers that are using products with low compatibility with our other nanocrystals.

When crosslinking the nanocrystals into the matrix is important to the application, we recommend the following catalog numbers of nanocrystals for testing:

Product 915750 and 915262 offer a methacrylate-functionalized nanocrystal option that is appropriate for methacrylated and acrylated material formulations. With this functionality, 915750 and 915262 can act as a crosslinker, allowing customers to reduce or potentially eliminate conventional di-, tri-, and higher functionality methacrylate and acrylate monomers in formulations. In films, the RI, mechanical properties, and degree of crosslinking can be changed by adjusting the loading of material in the formulation.

Acrylates show higher reactivities than methacrylates which may result in better incorporation into the matrix. Products 906501 and 915254 offer an acrylate-functionalized option, like 915750 and 915262, useful in methacrylated and acrylated material formulations. Products 906501 and 915254 could also prove beneficial in combination with the appropriate monomers for applications requiring lower UV energy for curing.

Products 916528 and 915505 represent ZrO2 nanocrystals with similar capping chemistry as 915750 and 915262 but with a higher surface coverage of the methacrylate functionality better higher crosslinking density as well as increased chemical resistance of the final film.

Materials

To continue reading please sign in or create an account.

Don't Have An Account?