Solutions for battery R&D and testing across the battery workflow

Our state-of-the-art solutions for battery development and testing drive innovation through the entire battery workflow. We deliver leading-edge battery materials and high-performance research products for battery R&D, designed to empower ingenuity with the highest standards of quality, reliability, and battery-grade specifications. In addition, we provide analytical testing solutions for key methodologies used in the critical testing of incoming and in-house manufactured materials. Our products ensure consistent performance and are backed by a trusted, global, and ethically sourced supply chain.

What do we offer?

- Comprehensive portfolio of high-quality reagents, biology materials, and labware for product development

- Expert-driven innovations to meet evolving battery market demands

- Ready-to-ship global supply for battery R&D and scale-up

- Reliable analytical solutions for common testing methodologies of raw materials and components

Scale up faster with confidence, backed by our expert technical support. Click here to request a consultation.

Battery Development Workflow

Achieving optimal battery performance begins with formulating a liquid electrolyte with the highest standards. Count on our extensive collection of battery-grade lithium salts, sodium salts, solvents, additives, and preformulated electrolyte solutions to set up your battery technology for success.

Click on the workflow steps below for more information.

Formulate

Choose the electrolytic salt and solvents that fit your application:

Add the right additives to boost your performance:

Fill

To ensure reliable performance, use our high-quality preformulated electrolytes:

- LiPF6-based electrolytes

- LiTFSI-based electrolytes

- Na-ion electrolytes

Solid electrolytes promise big performance advantages for batteries, but ensuring reproducibility is a demanding task. From synthesis of solid electrolyte materials to processing thin films, trust our high-purity precursors, solid electrolytes, solvents, and reagents to afford you control over the structure and interfaces and achieve top, reproducible performance.

Click on the workflow steps below for more information.

Synthesize

Take control of your solid electrolyte synthetic process using our high-purity precursors.

Process

Achieve dense thin films of your solid electrolytes with our processing materials

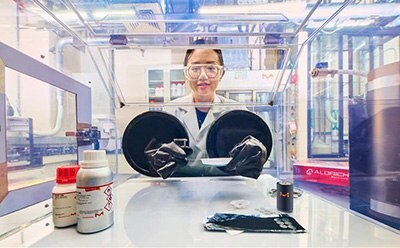

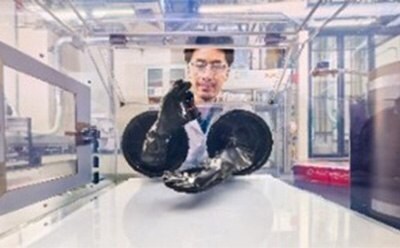

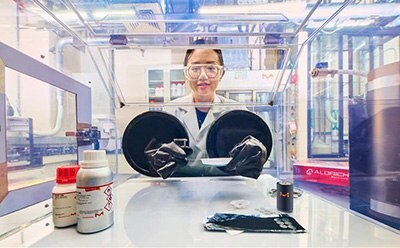

Electrode R&D, the confluence of synthesis, formulation, coating, and analysis, requires dozens of materials and processes to create a high-performance electrode. Trust our expertise and extensive range of electrode materials, including sheets, slurries, active materials, precursors, and more, so you can harness every milliampere-hour (mAh) and millivolt (mV) of performance from your battery.

Click on the workflow steps below for more information.

Synthesize

Discover the performance impact of using our battery-grade precursors.

Formulate the Slurry

Make formulation effortless: trust our high-quality ingredients for predictable slurry performance.

Coat

Achieve flawless coatings with our premium slurries, foils, and pre-made sheets.

Analytical Testing for Battery Materials

Analytical testing of battery materials is very important to determine the quality of incoming raw materials and internally manufactured materials. Various methodologies are used for battery materials testing.

Click on the techniques below for more information.

By identifying the elemental composition of materials, ICP analysis helps ensure the quality and reliability of battery components, ultimately enhancing energy efficiency and safety.

- Standards

Single Element Standards

Multi Element Standards: Periodic table mix 1 for ICP Part #92091 and Periodic table mix 2 for ICP Part #41135 - High-Purity Acids:

Nitric Acid

Sulfuric Acid - Ultrapure Water Systems

Gas Chromatography (GC)

A vital tool in battery testing, GC precisely analyzes electrolyte components like carbonate esters and additives. It helps optimize formulations to enhance battery performance, safety, and longevity by providing accurate, rapid, and reproducible results for quality control and research.

- GC Columns, Accessories & Adsorbents (Especially SLB(R)-5ms Columns):

GC Columns, Accessories & Adsorbents

Watercol 1910— Water quantification by GC -Convenient Measurement of Water by GC with Watercol™ Series Columns - Vials

- Syringes

- Gas generators

- Additional GC Accessories, such as ferrules, inlet liners, O-Rings, Gold-Plated Inlet seals, and septa: GC Columns, Accessories & Adsorbents

HPLC

Our large variety of HPLC columns and related consumables allow for enhanced characterization of your battery materials.

Chromatography reveals impurities and degradation products that may impact battery performance. By ensuring the purity and stability of materials, chromatography helps in optimizing battery formulations for improved efficiency and lifespan.

- IC Solvents

- IC Standards: Our IC standards provide an accurate benchmark for accuracy, reliability, and reproducibility in your analytical testing.

- Sample Preparation: We offer a wide range of sample preparation materials to aid in your battery testing workflow

- Ultrapure Water Systems

Coulometric Karl Fischer titration is an effective and fast method for accurately measuring the water content in battery materials. Excessive water content in battery materials can negatively impact battery performance, stability, and lifespan. Therefore, controlling water content is crucial for ensuring optimal functionality and longevity in battery systems.

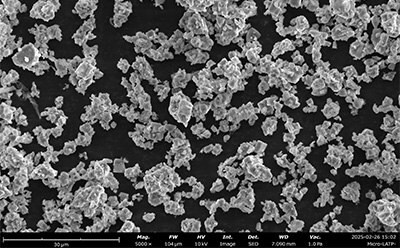

Physical & Chemical Property Testing

Understanding physical properties of battery materials allows for the optimization of material selection and design, ultimately enhancing battery durability and energy output.

Related Resources

- Brochure: Power the Future - Battery Materials

- Article: Solid-State Rechargeable Batteries

Solid-state Li batteries: Review of solid electrolytes, ion conduction, structures, and electrochemical processes.

- Article: Lithium-Ion Battery Performance Factors

Lithium-ion batteries' characteristics make them popular for electricity storage due to portability, rechargeability, and low cost.

- Article: Electrode Materials for Li-ion Batteries

Solid oxide fuel cells and electrolyzers show potential for chemical-to-electrical energy conversion, despite early development stages.

- Article: Safer High-Performance Electrodes, Solid Electrolytes, and Interface Reactions for Lithium-Ion Batteries

Li-ion batteries are currently the focus of numerous research efforts with applications designed to reduce carbon-based emissions and improve energy storage capabilities.

- Article: Rise of Electrolyte Additives in Advancing Lithium ion Battery

Explore advancements in lithium-ion batteries with liquid electrolytes and additives, revolutionizing critical applications.

- Article: Nanomaterials for Energy Storage in Lithium-ion Battery Applications

Nanomaterials for Energy Storage in Lithium-ion Battery Applications

- Article: Atomic Layer Deposition of Nanomaterials for Li-Ion Batteries, Fuel Cells, and Solar Cells

Nanomaterials are considered a route to the innovations required for large-scale implementation of renewable energy technologies in society to make our life sustainable.

- Article: Olivine-Type Cathode Materials for Li-Ion Batteries

Lithium-ion batteries offer high energy density and cyclic performance for portable electronic devices.

- Article: DOE's Materials Research for Advanced Lithium Ion Batteries

HEVs address rising fuel costs and emissions concerns, utilizing battery packs alongside internal combustion engines for enhanced performance.

- Article: Ionic Liquids for Rechargeable Batteries

Ionic liquid electrolytes explored for rechargeable batteries' advancement; future IL development discussed.

- Article: MXenes Empowering Next Gen Batteries and Hydrogen Evolution

Discover how MXenes' superior conductivity, strength, and stability are revolutionizing energy. Explore their potential for next-gen batteries and hydrogen evolution.

To continue reading please sign in or create an account.

Don't Have An Account?