High Performing Platforms for Lentivirus and AAV Manufacturing

VirusExpress® 293T Lentiviral Production Platform Performance

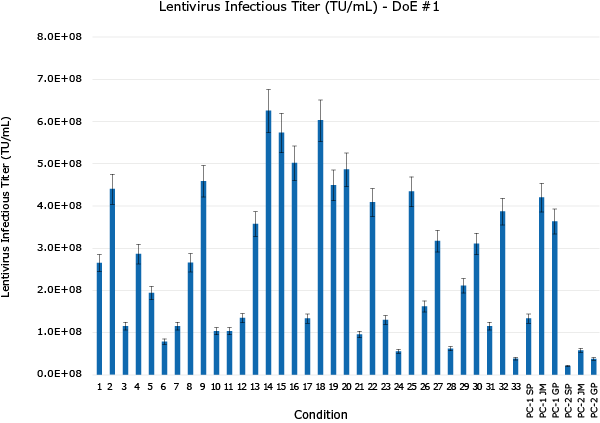

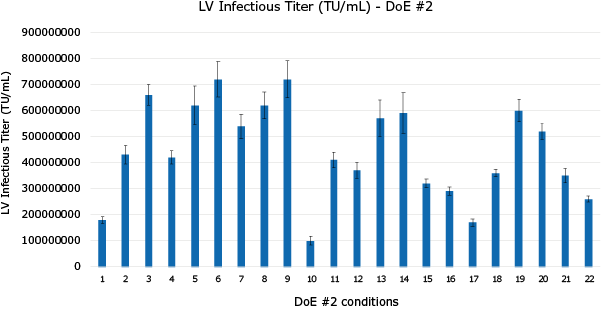

Optimization of Lentivirus Production using Design of Experiment (DoE) Tool. DoE #1 was designed to optimize total DNA/mL, PEI:DNA ratio, complex formation volume (%), transfection cell density and complex formation time (Figure 1) while plasmid ratios were studied in DoE #2 (Figure 2).

Figure 1.

Figure 2.

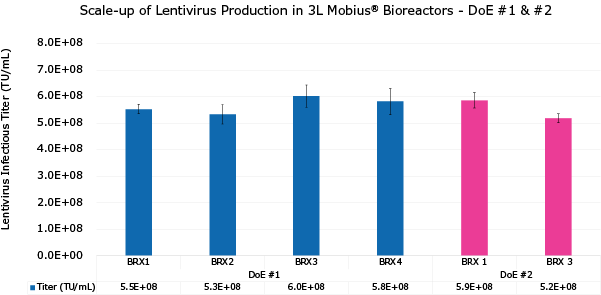

Figure 3. Scale-up in a Mobius® 3L Single-Use Bioreactor: Optimal level of each parameter for transient transfection step was scaled-up and greater than 5E+08 TU/mL infectivity titer was obtained in bench-top bioreactors.

Figure 3.

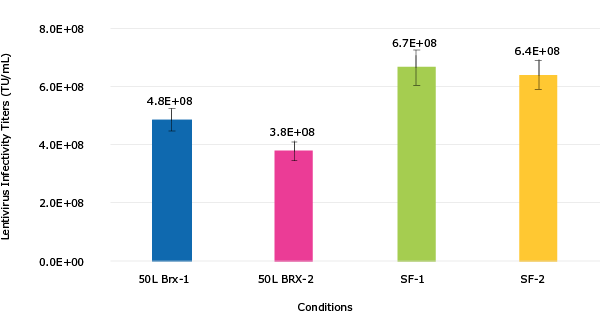

Lentivirus Production in Mobius® 50L Single-Use Bioreactor

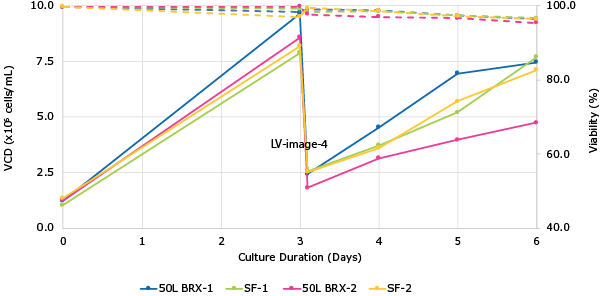

Figure 4. VirusExpress® 293T Lentiviral Production Cells were expanded in Mobius® 50 L Single-Use Bioreactor at N-1 stage for 3 days, and then fresh medium was added volume up to 40L working volume. Cells were grown for 1 day prior to transfection with PEI based transfection reagent and 3rd generation lentivirus packaging plasmids and transfer plasmid with GFP reporter gene. A total of 2 runs were completed. Solid lines are cell growth data while dashed lines are cell viability (Figure 4). The bar graph consists of lentivirus infectivity titers obtained with HT1080 cells (Figure 5).

Figure 4.

Figure 5.

VirusExpress® 293 AAV Production Platform Performance

Viral Vector Productivity in Bioreactor

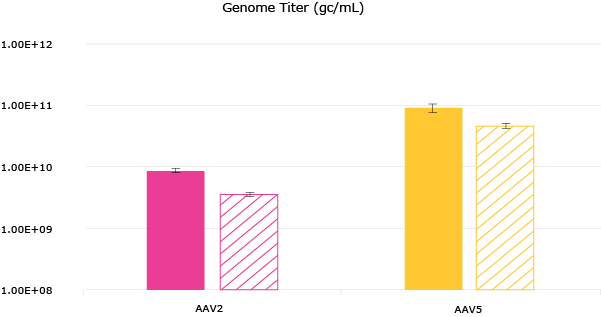

Figure 6. VirusExpress® 293 AAV Production Cells – AAV2 and AAV5 crude harvest genome titers (gc/mL) titers of GFP model virus in Mobius® 3L Single-use Bioreactors (solid color bars) and in shake flasks (striped color bars) using PEI based transfection. For AAV2 - n=6 for bioreactor and n=9 for SF; for AAV5, n=3 for bioreactor and n=6 for SF.

Figure 6.

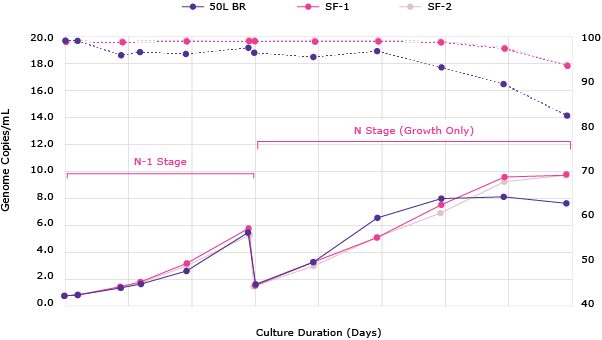

Cell Growth in Bioreactor

Figure 7. VirusExpress® 293 AAV Production Cells were cultured for batch growth in Mobius® 50 L Single-Use Bioreactor. Cells were seeded at 6 x 105cells/mL and diluted with fresh media on Day 3. Peak viable cell density (VCD) of 8 x 106cells/mL was obtained in Mobius® 50L bioreactor with viability >90%.

Figure 7.

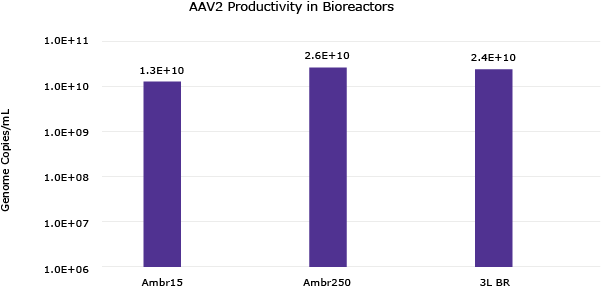

Productivity by Serotype

Figure 8 and 9. Productivity of VirusExpress® 293 AAV Production Cells shown as crude harvest genome titers (gc/mL) of GFP model virus in shaker flasks or various bioreactor platforms for multiple serotypes: AAV2, AAV5 and AAV6.

Figure 8.

Figure 9.

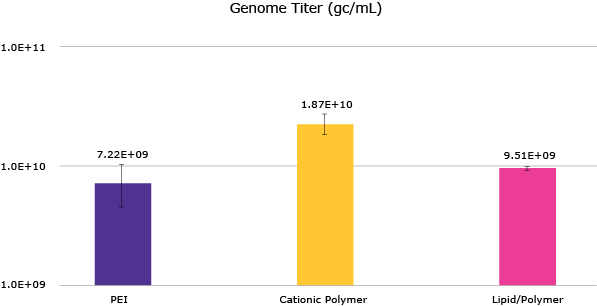

Productivity Using Alternative Transfection Reagents

Figure 10. Crude harvest genome titers (gc/mL) of GFP AAV2 model virus produced by VirusExpress® 293 AAV Production Cells in shake flasks using PEI-based transfection versus alternative transfection reagents.

Figure 10.

The Sf-RVN® Platform Performance for Growth and AAV Production

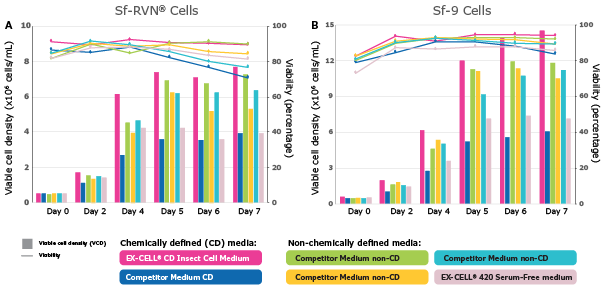

Growth Performance Evaluation

Figure 11. EX-CELL® CD Insect Cell Medium is the best medium tested to support Sf-RVN® and Sf-9 cells growth. Cells were adapted for at least five passages in six different cell culture media. Two of them are chemically defined (including the EX-CELL® CD Insect Cell Medium) and the four others are not chemically defined and contain hydrolysates. After adaptation, cells were seeded 0.5x106 cells/mL on day zero. Viable cell density (VCD) and viability were followed for 7 days.

Figure 11.

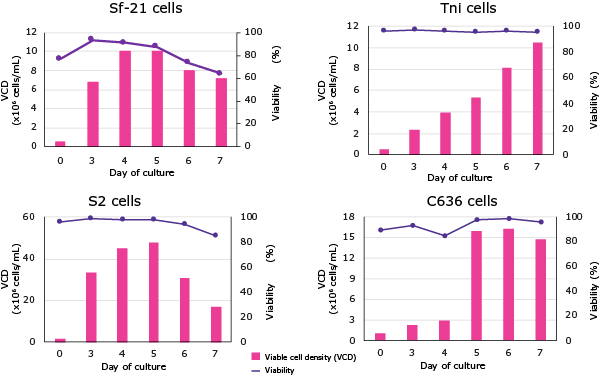

Figure 12. EX-CELL® CD Insect Cell Medium supports the growth of multiple insect cells. Sf-21, Tni, S2 and C636 cells were adapted for at least three passages in the EX-CELL® CD Insect Cell Medium. After adaptation, cells were seeded at 0.5x106 cells/mL on day zero. Viable cell density (VCD) and viability were followed for 7 days.

Figure 12.

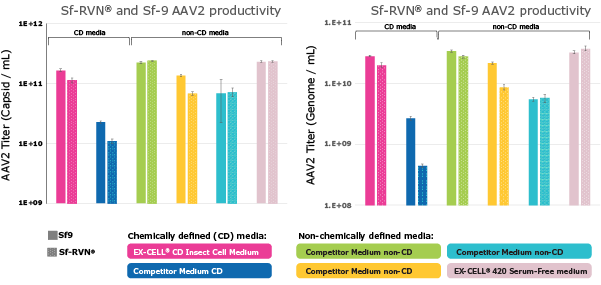

Evaluation of Performance for AAV Production

Figure 13. EX-CELL® CD Insect Cell Medium is the best chemically defined medium tested for AAV2 production in Sf-RVN® and Sf-9 cells. Cells were adapted for at least five passages in six different cell culture media. Two of them are chemically defined (including the EX-CELL® CD Insect Cell Medium) and the four others are not chemically defined and contain hydrolysates. Cells were seeded at 2x106 cells/mL, infected with both ITR-GFP and AAV2-RepCap baculoviruses at an MOI of 0.01 and an equal ratio. Samples were harvested at 120 hours post infection (hpi) and the AAV2 productivity was assessed by ELISA (Capsid / mL) and ddPCR (Genome / mL).

Figure 13.

Related Products

To continue reading please sign in or create an account.

Don't Have An Account?