How To Cast Gels Faster with the mPAGE® Lux Gel Casting System for SDS-PAGE Gels

Discover the mPAGE® Lux Casting System for ready-to-use SDS-PAGE gels in 3 minutes. Fresh SDS-PAGE gels that are ready when you need them. Interested? Request info below.

Gel Casting Made Easy

How do you cast a gel for SDS-PAGE? Gel casting typically involves pouring resolving and stacking gels in a time-consuming, stepwise process. Researchers traditionally have few options to meet their gel casting and electrophoresis needs. Our innovative mPAGE® Lux SDS-PAGE Gel Casting System is designed to provide the flexibility of hand-cast gels and the reliability of precast gels, without the loss of quality, time, or the significantly higher cost that accompany the alternative options. Gels in less than three minutes with our mPAGE® Lux Casting System. You can say farewell to conventional methods and their time consuming, manual steps for gel creation. That’s fresh.

Section Overview

- mPAGE® Lux Gel Casting System Features and Benefits

- What Are the Steps of Gel Casting?

- mPAGE® Lux Casting System and Bis-Tris Reagent Kit

- mPAGE® Lux SDS-PAGE Gel Cast Protocol

- mPAGE® Lux Bis-Tris Gels with MOPS and MES Running Buffers

- Sustainable Gel Casting with mPAGE® Lux Casting System

- Rapid Visualization of In-Gel Protein Detection Without Staining Using the mPAGE® Lux System

- Order the mPAGE® Lux Casting System and Related Reagents

mPAGE® Lux Gel Casting System Features and Benefits

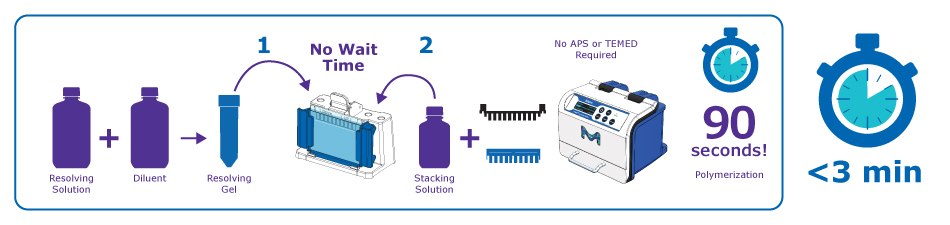

mPAGE® Lux Gel Casting System replaces your protein gel casting process with faster, simpler, and safer methods with more reproducible results. Cure a mini gel in 90 seconds with the mPAGE® Lux Casting System compared to conventional methods that take more than 90 minutes. Our quick casting workflow with UV irradiation expedites curing of mPAGE® Lux Bis-Tris reagents while Bis-Tris gel chemistry allows for shorter run times compared to conventional methods. See how to make protein gels with this casting system in the video below.

The one-step photopolymerization using precise system controls along with less preparation steps means there are fewer chances for error. Our mPAGE® Caster prevents leakage and the use of Bis-Tris gels provides superior band quality compared to hand-cast Tris-Glycine gels. Additionally, the mPAGE® Lux Reagent Kit, mPAGE® TurboMix Reagent Kit, and mPAGE® precast gels all use Bis-Tris chemistry and share the same running buffers and gel stains. Our mPAGE® Lux Casting System does not use APS or TEMED and offers a safer option using fewer toxic chemicals.

To further improve compatibility and your workflow needs, we now offer our mPAGE® Clip-on Mask. With the mPAGE® Clip-on Mask, Bio-Rad Mini-PROTEAN® Short Plates, Spacer Plates and Combs as wells as mPAGE® Mini Short Plates, Spacer Plates and Combs can be used when curing a gel using the curing system, the mPAGE® Lux Curing Station.

Note: The mPAGE® Lux Masked Short Plate is no longer required when the Clip-on Mask is used, though the Masked Short Plate can still be used as well.

Traditional Hand Cast Workflow

Figure 1.Traditional Hand Cast Workflow for SDS-PAGE gels infographic showing extended steps and polymerization time of 90 minutes or more.

mPAGE®Lux Workflow

Figure 2. Traditional Gel Casting vs the mPAGE® Lux Workflow. The mPAGE® Lux Casting system has fewer overall steps, reduced polymerization time, and less toxic waste compared to traditional gel casting technology. Gels created by mPAGE® Lux Casting System are compatible with mPAGE® Mini-gel Tank and the Bio-Rad Mini-PROTEAN® Cells. For outstanding resolution and reduced run times, use our mPAGE® buffers. mPAGE® Lux gels are compatible with Bis-Tris compatible buffers and staining reagents.

What Are the Steps of Gel Casting?

Casting an SDS-PAGE gel often includes weighing, premixing gel solutions, casting, and wait time for polymerization. While often cited as a more economical solution, conventional hand-cast gel methods are time-consuming, requiring many hands-on steps, which may result in inconsistent gel formulations. The quality of hand-cast gels and the data they may help generate rely on formulation consistency in protein gel recipes so that precious reagents and time are ultimately not wasted with gel failures.

Figure 3.Data quality comparison with mPAGE® Lux Bis-Tris gel and hand-cast tris-glycine gel. Band quality of mPAGE® Lux Bis-Tris gel (left) compared to hand-cast tris-glycine gel (right). Both gels are 10% acrylamide and loaded with a titration of A431 human cell lysate. Electrophoresis run time is 42 minutes at 200V (Lux gel) and 119 minutes at 120V (tris-glycine gel). Gels are stained with ReadyBlue™ Coomassie gel stain.

The mPAGE® Lux Casting System offers an innovative solution to your gel casting process. You no longer must choose either saving time or resources. Our novel gel casting system allows researchers to easily cast their gels quickly when they need them, at a fraction of the cost of precast gel technologies. Improve your lab efficiency and upgrade your gel electrophoresis workflow with the mPAGE® Lux Casting System.

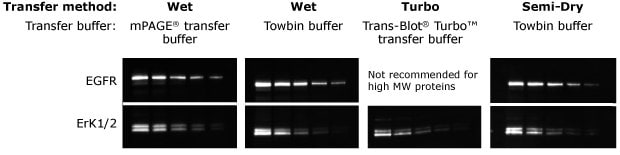

Figure 4. Western blotting for wet, fast, and semi-dry transfer method comparison. Comparisons were performed using 12% mPAGE® Lux Bis-Tris gels that were run with a titration of A431 human cell lysate and with various transfer methods onto Immobilon®-P membranes. Membranes were blotted with anti-EGFR and anti-ErK1/2 antibodies, then detected with Immobilon® ECL Ultra Western HRP substrate. Turbo method = transfer using Bio-Rad Trans-Blot® Turbo™ Transfer System and Trans-Blot® Turbo™ Transfer Packs.

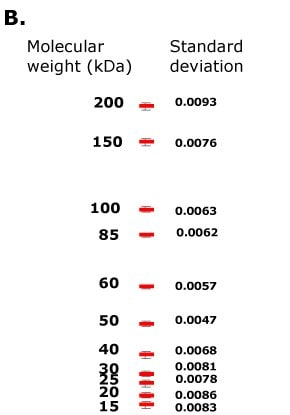

Figure 5. Reproducibility of mPAGE® Lux Bis-Tris gels. A. Four 8% gels were cast and run with titration of A341 human cell lysate subsequently stained with ReadyBlue™ Coomassie gel stain. B. The relative migration distance (Rf) for the unstained molecular weight marker was calculated for each gel. Standard deviation is shown for each protein band.

Figure 6.mPAGE® Lux Bis-Tris reagent shelf-life analysis. mPAGE® Lux Bis-Tris gels cast using reagents (A) 0 months, (B) 6 months, or (C) 12 months old, or (D) 24 months old. No difference is observed in running pattern or run time.

mPAGE® Lux Casting System and Bis-Tris Reagent Kits

Add mPAGE® Lux Casting System to your lab and have ready-to-use Western blot gels and electrophoresis gels in under 3 minutes. Take a breath and get used to a fast gel casting process with less waste and without the worry of failure. That’s fresh. Take advantage of our mPAGE® Lux Casting System Kits of the mPAGE® Lux Curing Station, mPAGE® Lux Mixing Tube, mPAGE® Gel Caster, mPAGE® Comb with 10 wells and 15 wells, mPAGE® Mini Spacer Plate, mPAGE® Lux Masked Short Plates with 10 wells and 15 wells. Casting kit descriptions and configurations follow:

Figure 7.mPAGE® Lux Curing Station.

The mPAGE® Lux Bis-Tris Reagent Kit is a dedicated reagent kit for the mPAGE® Lux Casting System. The mPAGE® Lux Bis-Tris Reagent Kit consists of 3 components, Resolving Solution, Diluent, and Stacking Solution. The kit supports a variety of acrylamide gels between 8.0-13.5%. mPAGE® Lux Reagent Kit description and configuration follows:

mPAGE® Lux SDS-PAGE Gel Cast Protocol

All solutions must be protected from sunlight to prevent polymerization. Before casting gels, bring all solutions to room temperature.

Resolving Gel

- Prepare Resolving Gel solution by mixing Resolving Solution and Diluent. See the table below for mixing volumes. Resolving gel solution may be prepared in a large batch to make several gels sequentially.

- Using a clean pipette, add Resolving Solution to a black mixing tube or other opaque container.

- Using a clean pipette, add Diluent to the same mixing tube.

- Mix by gently turning container end over end. Do not vortex.

Resolving Gel Solution Volumes

Use the below volumes to make a single 1.0 mm gel. For 0.75 mm and 1.5 mm solution volumes, see the full user guide available on the product page.

Stacking Gel

The Stacking Solution is ready to use directly from the bottle. Use 1.5 mL Stacking Solution for a 1.0 mm gel. Important: Do not dilute Stacking Solution.

Gel Casting

- Clean glass plates with mild detergent and rinse with DI water. Wipe with 70% Ethanol before use.

- Assemble mPAGE® Gel Caster using mPAGE® Spacer Plate and mPAGE® Lux Masked Short Plate to form glass cassette. The masked short plate should be oriented with the text on the left side of the cassette. Ensure that both glass plates are aligned at the bottom of the caster frame before closing caster clamps. Note: The mPAGE® Lux Masked Short Plate must be used with the mPAGE® Curing Station.

- Power on mPAGE® Lux Curing Station by pressing the power button. The Curing Station will initiate a self-test. After self-test is complete, the ready screen will appear.

- Open door and place gel caster into Curing Station, aligning caster behind the bumpers.

- Using a clean 5 mL pipette, add prepared Resolving Gel Solution to the indicated fill line on the mPAGE® Gel Caster frame.

- Using a clean 5 mL pipette, slowly add Stacking Solution up to the top of the short plate.

- Slowly insert the mPAGE® comb at an angle to prevent air bubble formation under teeth. Important: Mixing different well formats may result in improper well formation. Use:

- 10-well combs with 10-well mPAGE® Lux Masked Short Plates

- 15-well combs with 15-well mPAGE® Lux Masked Short Plates

- Wipe solution spill-over from front of short plate to prevent incomplete curing where spill-over exists.

- Install the Clip-on Mask over the short plate and casting frame.

- The front of the mask should sit snugly against the short plate, covering the comb teeth completely.

- Close Curing Station door and select gel thickness.

- Press Start to begin gel curing. Tip: If casting multiple gels, begin the Gel Casting process with second Gel Caster now, while the first gel is curing.

- After curing is complete, open door and remove Gel Caster. Remove cassette from Gel Caster by lowering the tension clip to release the caster frame. Then open the sides of the frame and slide cassette out from top.

- Use gel immediately or wrap the cassette in wet paper towel and store lying flat in a zip top bag or other airtight container at 2-8 °C for up to 2 weeks. Do not leave cassettes unwrapped as the gel will dry out.

mPAGE® Lux Bis-Tris Gels with MOPS and MES Running Buffers

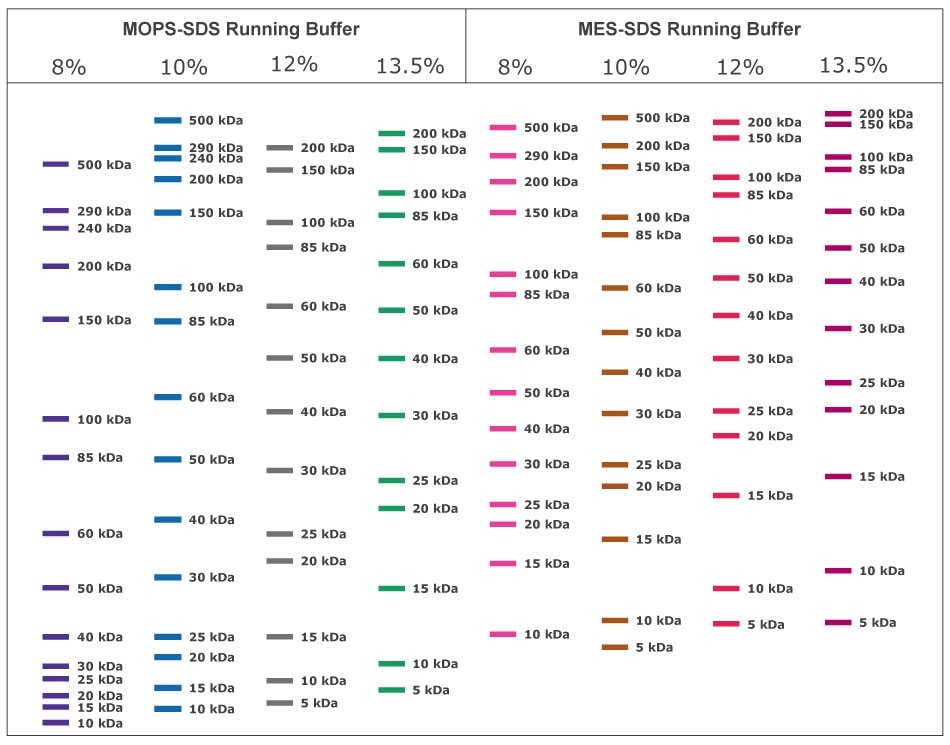

mPAGE® Lux Bis-Tris Gels are designed to work exclusively with MOPS or MES running buffer. Depending on which running buffer is used, very distinct separation patterns can be achieved. MOPS buffer can be used to fine-tune the separation of large and medium-sized proteins, whereas MES buffer provides optimal separation of smaller proteins. Refer to the migration charts (Figure 8) to determine which gel running buffer system is best suited for the intended separation range.

Figure 8.Migration Charts of mPAGE® Lux Bis-Tris Gels with MOPS SDS Running Buffer and MES SDS Running Buffer (kDa).

How To Remove Gel After Electrophoresis

Remove the gel from glass cassette using a gel scraper. Cut along gel edges (right) to avoid gel tearing. mPAGE® Lux Bis-Tris gels should ONLY be used with MOPS-SDS or MES-SDS running buffer. Bis-Tris gels are NOT compatible with Tris-Glycine running buffer.

Sustainable Gel Casting with mPAGE® Lux Gel Casting System

To quantify the sustainable impacts made by our mPAGE® Lux Casting System, calculations were performed against the use of a representative fast cast kit for hand-casting polyacrylamide gels for protein electrophoresis. Both systems require the use of reusable casting kits and hand-casting reagent kits. The mPAGE® Lux Casting System additionally requires the use of the mPAGE® Lux Gel Curing Station while the baseline system requires the use of APS & TEMED, which are sold separately from the hand-casting reagent kit.

All components required for casting electrophoresis gels over the minimum service lifetime of the mPAGE® Lux Curing Station, which is 5 years are considered in this evaluation. This includes the production, packaging, distribution, use and end-of-life impacts of the handcasting kit, the necessary reagents and all consumable labware required. Calculations were performed assuming 250, 500 or 1000 gels produced per year and the minimum difference over the baseline system was claimed.

Material and Product Sustainability Attributes

While being an innovative workflow solution for hand-casting polyacrylamide gels, the mPAGE® Lux Casting System still requires some use of plastic consumables and hazardous reagents. While no suitable replacement for acrylamide exists in this application, all remaining chemical hazards were eliminated from this system and the amount of plastic consumables required is significantly reduced over the baseline system.

The additional mass of the Gel Curing Station required by the mPAGE® Lux Casting System is offset by the reduction in products required in the gel casting workflow, as shown on the graph. Throughout the lifetime of the instrument, total system mass is reduced by at least 20 % compared to fast cast systems.

Lifetime system mass (kg) for casting 500 gels/year:

Figure 9.Comparison of the lifetime system mass (kg) for casting 500 gels/year for the mPAGE® Lux Casting system and reference product system. Dark blue = Reference product system. Light blue = mPAGE® Lux Casting System.

Additionally, this product adheres to the principles of SMASH Packaging, our strategy that drives packaging sustainability improvements through less packaging, more sustainable materials, and easier recycling.

- Packaging for products and additional items required for a functional unit are reduced by 30% over the baseline system.

- 100% of system fiber-based packaging have sustainable forestry certification.

- All protective foam inserts made from 100% recycled polyethylene.

- Packaging does not contain any materials which would inhibit recycling as defined by our SMASH guidelines.

mPAGE® Lux Casting System Distribution and Product Use

The reduction of required consumables and the elimination of certain reagents results in a significant decrease in impacts associated with shipping. The mass reduction in regularly shipped components and associated packaging is at least 24% over the minimum service lifetime of the instrument.

While the added instrument does require energy during operation, the mPAGE® Lux Casting Station was designed with energy efficiency in mind. By utilizing LED Lighting and a simple yet intuitive user interface, the overall energy consumption remains remarkably low. The cumulative energy consumption required to cure 1000 gels is only 1.65 kWh, equivalent to approximately 33 hours of laptop use. The amount of single-use plastic waste generated throughout the gel casting workflow is reduced by at least 25%. Additionally, mPAGE® Lux reagents will self-polymerize under exposure to ambient lighting, eliminating unpolymerized acrylamide residue in waste streams.

By casting fresh, ready-to-use gels as needed, the risk of pre-preparing gels which will go unused is eliminated. The mPAGE® Lux System removes the need to stock reagent kits or pre-cast gels in different percentages, which reduces the amount of waste generated due to component expiration. The mPAGE® Lux Curing Station is electronic equipment, and as such must be disposed of in compliance with all applicable regulations. For more information on disposal of electronic waste, visit our WEEE Compliance page.

This product has demonstrated significant improvements over the baseline system throughout the entire product life cycle and has been designated as a Greener Alternative Product. For more information, visit our page on our Design for Sustainability framework and our Greener Alternative Products.

Rapid Visualization of In-Gel Protein Detection Without Staining Using the mPAGE® Lux System

SDS-PAGE is a common technique used to separate proteins and other biomolecules by size. Proteins within the gel can be detected using well-established colorimetric or fluorescent stains, like Coomassie Brilliant Blue (CBB), Silver Stain, and SYPRO™ Ruby. These staining methods vary in sensitivity and often require several time-consuming incubation steps.

First described as a fluorescent quencher, trichloroethanol (TCE) is a compound that shifts tryptophan fluorescence from its native emission (~350 nm) towards visible light (~512 nm) by producing a new fluorophore upon activation with UV light.1-3 This property of TCE and other trichloro compounds was exploited by Kazmin et. al. to develop a fast and sensitive one-step gel staining solution.4 Later, TCE was incorporated directly into SDS-PAGE gels during gel preparation which allowed detection of proteins without cumbersome staining steps.5,6 Here we describe preparing mPAGE® Lux gels with TCE to allow for in-gel protein detection without staining.

Staining vs Stain-Less Method Comparison

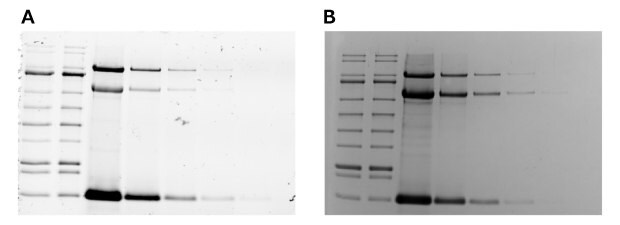

Comparison between TCE visualization and Coomassie gel stain methods was performed. The sensitivity of detection was similar between the two methods (Figure 10). However, the TCE-based detection does not require the staining step, saving at least two to several hours of prep time, depending on your current staining method.

Figure 10.Protein Visualization with TCE Compared to READYBLUE® Coomassie Gel Stain. Three purified proteins (Lysozyme (14.4 kDa), BSA (66 kDa), Phosphorylase b (97 kDa)) are loaded with 4 µg, 1 µg, 0.25 µg, 0.0625 µg, 0.0156 µg, 0.004 µg, 0.0009 µg, and 0 µg respectively in a 12% mPAGE® Lux gel prepared with 1% TCE. The gel was run for 42 minutes at 200 V in MOPS-SDS running buffer. (A) Protein visualization after 45 seconds of TCE activation. (B) Corresponding READYBLUE® Coomassie stained gel image. Similar protein detection sensitivity is observed between TCE-induced and Coomassie stained gel.

Method Compatibility

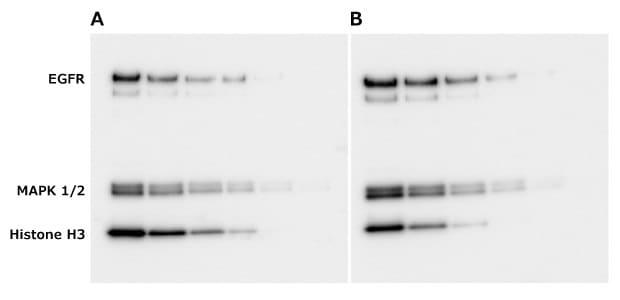

Compatibility of this method with downstream analysis, in this case Western blotting, was also performed. Figure 11 shows a comparison of a Western blot prepared with and without TCE. Similar immunodetection sensitivity was observed when the Western blot gels were activated for 45 seconds and imaged prior to transfer, as shown here.

However, due to the nature of mPAGE® Lux gel polymerization, longer activation and exposure times can alter protein transfer efficiency. Protein transfer may need to be optimized. If Western blotting will be performed after TCE visualization, it is recommended to use the shortest activation time possible because the activation can affect the transfer efficiency of the mPAGE® Lux gels.

Figure 11.Western Blot After TCE Visualization. A 2x dilution series of EGF-stimulated A431 cell lysate (10 ng – 0.3 ng) was loaded into an 8% mPAGE® Lux gel prepared (B) with or (A) without 1% TCE. The gel was run for 38 minutes at 200 V in MOPS-SDS running buffer, then the gel containing TCE was activated for 45 seconds and imaged. Both gels were then transferred to an Immobilon® P PVDF membrane. The membranes were probed for EFGR, MAPK 1/2, and Histone-H3 using standard immunodetection methods.

Stain-Less Technology with TCE Activation

Because this TCE activation method does not require an extra staining step, it saves time and can be done immediately after electrophoresis. The results here also show that the sensitivity of protein detection is similar to other conventional methods that use staining.

Overall, using mPAGE® Lux gels and other mPAGE® electrophoresis products, you can quickly and reproducibly make and run gels. In addition, mPAGE® Lux gels are compatible with the stain-less technology described here using TCE, so it further reduces steps in your current protocols. This provides researchers with a valuable tool to still rely on the ease and flexibility of mPAGE® Lux casting technology, while now also getting the added benefit of rapid protein visualization.

mPAGE® Lux Casting System

mPAGE® Lux Accessories and Reagents

References

To continue reading please sign in or create an account.

Don't Have An Account?