Nanostructured Olivine-based Cathode Materials for Lithium-ion Batteries

Introduction

Due to the adverse impact of the continued use of fossil fuels on the earth’s environment and climate, researchers have been asked to develop new approaches for producing power using renewable sources like wind and solar energy.1 Although renewable energy sources are abundant, they are highly intermittent in nature, which makes advancement in renewable energy difficult without further development of electrical energy storage systems. Lithium-ion batteries (LIBs) have favorable energy and power densities that arise from high electromotive force generated by the high electrochemical reactivity of Li+.1 The physicochemical properties of ionic transport, electron transport, and electrochemical kinetics must be precisely balanced in order to efficiently convert the chemical energy to be stored in batteries.2–4 We have developed new approaches to more effectively achieve this balance by shifting from micro-sized particles to nano-sized particles and adding conductive wiring to the surface of the nano-sized particles.3

The overall storage properties of LIB depend upon the materials used for cathodes, anodes, and electrolytes.5 In this regard, various classes of inorganic cathode materials have been investigated.4 We focus on polyanion-based cathode materials for Li storage (i.e., phosphates), emphasizing the role of nanoscale design on electrochemical kinetics and lithium storage performance.

During the electrochemical redox reaction, guest species such as Li+ are reversibly intercalated and deintercalated into the host lattice of the electrode materials. The specific storage capacities of electrodes are estimated based on the reversible insertion/extraction of Li+ ions during electrochemical processes. For example, orthorhombic phospho-olivine LiMPO4 (M = Fe, Mn, Co, or Ni)6 cathode materials enable the reversible intercalation/deintercalation of 1 mole of Li per formula unit with a theoretical capacity of 170 mAh g-1. Unlike other oxide-based cathode materials, the phospho-olivine framework is very stable because of its strong P–O covalent bonding which prevents oxygen release.7 Intrinsic structural stability makes these materials safe candidates for electric vehicle applications. One of the most widely studied cathode materials, lithium iron(II) phosphate (LFP, Prod. No. 759546), exhibits a specific energy of 586 Wh kg-1 (170 mAh g-1 × 3.45 V).6,8–9 Besides LFP, lithium manganese phosphate (LMP), also offers a high specific energy of 701 Wh kg-1 (171 mAh g-1 × 4.1 V) arising from its high Mn2+/Mn3+ redox voltage (~4.1 V vs. Li/Li+).10–15 However, the energy density of LMP is limited by its low electronic conductivity, ionic diffusivity,7,16 interfacial strain between the LiMnPO4/MnPO4 phases,17 and Jahn-Teller distortion.18

Our scalable synthetic approach for the production of nanostructured LiMPO4 (M = Fe and/or Mn) as well as the electrochemical properties of the nanostructured LMP cathode material is presented here. Phosphatebased cathode materials synthesized by the soft template-method assisted high energy ball milling method with carbon black attain reduced particle size and enhanced carbon wiring formation as described in our earlier reports.13–14 A nanostructure with divalent cation substitution can further enhance the lithium storage properties, making it a prospective candidate for practical applications.

Synthesis of Nanostructured Phosphatebased Cathode Materials

We dissolved 0.01 M of the cationic surfactant hexadecyltrimethylammonium bromide (Prod. No. H5882) in a mixture of absolute ethanol and milli-Q/DI water in a V/V ratio of 5:1 to form micelles. Following this, manganese(II) acetate tetrahydrate (Prod. No. 221007) and/or iron(II) acetate (Prod. No. 517933) and lithium dihydrogen phosphate (Prod. No. 442682) were added in stoichiometric ratio and stirred for 24 h. The solvents were evaporated using a Heidolph Hei-VAP rotary evaporator. The final product was calcined in a furnace at 650 °C for 6 h in an Ar-H2 (95:5) gas environment. Pure LiMPO4 (M = Fe and/or Mn) materials were milled together with carbon black using a FRITSCH premium line high energy ball mill at 500 rpm for 4 h.13–14 Further mild heat treatment was carried out at 500 °C for 3 h in an Ar-H2 atmosphere to relieve any stress developed during the ball mill process.

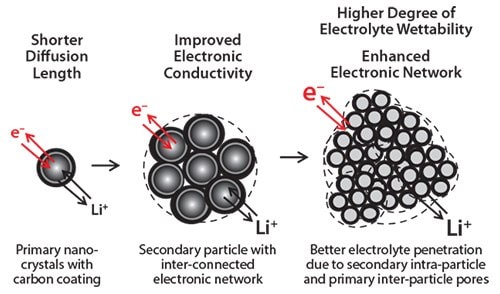

Figure 1.Schematic of nanostructuring strategies to improve the electrochemical properties of inorganic electrode materials

Figure 1 represents nanostructuring strategies used to enhance the lithium storage performance of LiMPO4. (M = Fe and/or Mn). The particles are comprised of interconnected nano-crystals and mesopores with a conductive carbon coating. These particles were prepared using the soft template assisted high energy ball mill method. This material architecture offers the advantages of short transport length, improved electronic conductivity, and improved electronic network due to interconnectivity of primary (particle–particle) and secondary particles. The material also includes pores that provide penetration of the organic electrolyte, facilitating rapid insertion/extraction of lithium ions in the electrode materials.

Electrochemical Properties of Nanostructured LiMnPO4 Cathode Materials

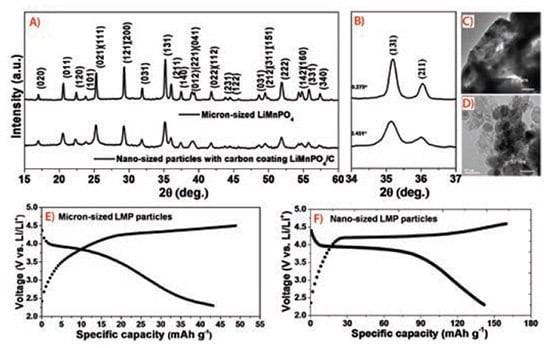

Figure 2A presents the X-ray diffraction (XRD) patterns of micron-sized and nano-sized LMP samples. All the Bragg peaks were indexed to the Pmnb space group (JCPDS Card No. 33-0803) with an olivine structure. The expanded XRD 2θ region (Figure 2B) shows that peak broadening increases as particle size decreases. No significant changes were observed in the lattice parameters. Transmission electron microscopy (TEM) images of micron-sized (M-LMP) and nano-sized LMP/C (N-LMP/C) samples are displayed in Figures 2C and 2D, respectively. The M-LMP particle size is ~400 nm, while N-LMP/C has a particle size of 40–50 nm. Notably, the surface area of N-LMP/C sample is higher (~46 m2 g-1) than the M-LMP sample (~9.9 m2 g-1).

Figure 2.A) XRD patterns (JCPDS Card No. 33-0803) for micron-sized LiMnPO4 and nano-sized LiMnPO4/C samples. B) Expanded 2θ region illustrating the peak broadening. C) TEM image of micron-sized LMP. D) TEM image of nano-sized LMP; charge-discharge profile of E) micron- and F) nano-LMP/C at 0.05 C.

The storage performance was then evaluated using the galvanostatic cycling process. The corresponding voltage-specific capacity profile for micron- and nano-LMP samples are presented in Figures 2E and 2F. The charge-discharge plateaus of the M-LMP sample corresponding to Mn2+/ Mn3+ redox potentials are seen at ~4.31 V and 3.95 V vs. Li/Li+ (Figure 2E) while the redox potentials of the nano-sized LMP/C sample occurs at ~4.27 V and 3.97 V vs. Li/Li+ (Figure 2F). A better extraction/insertion plateau of lithium ions is observed for the N-LMP/C sample with a higher discharge capacity of 140 mAh g-1 compared to the M-LMP sample which exhibits only 43 mAh g-1 at 0.05 C over the voltage window of 4.6–2.3 V at room temperature. This improved electrochemical property of N-LMP/C is ascribed to nanoparticles with a higher surface area and carbon coating.

Electrochemical Properties of Nanostructured LiFexMn1-xPO4/C (x = 0.2, 0.5, and 0.8) Cathode Materials

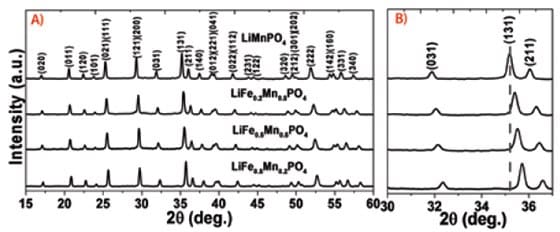

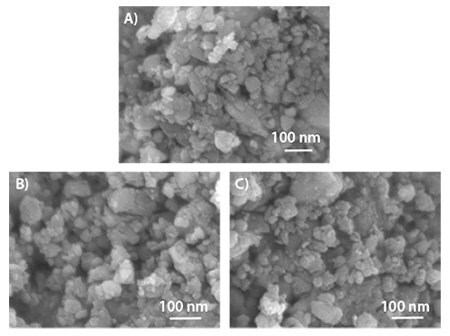

Nanostructuring of the LMP particle along with carbon coating improved the electrochemical performance. However, we observed that complete extraction and insertion of lithium is not possible in N-LMP. Therefore, to further improve the electrochemical performance of N-LMP/C, the Fe2+ cation was substituted for Mn2+. The Fe2+-substituted LiFexMn1-xPO4/C (x = 0.2, 0.5, and 0.8) samples were prepared using the high energy ball mill-assisted soft template method as described earlier. Figure 3A shows the XRD of the LiFexMn1-xPO4/C (x = 0.2, 0.5, and 0.8) samples. All the Bragg peaks belong to the Pmnb space group (JCPDS Card No. 33-0803). The expanded 2θ region as presented in Figure 3B indicates a continuous shift in the peak positions, revealing formation of Mn-Fe mixed compositions. Field Emission Scanning Electron Microscope (FESEM) images of LiFexMn1-xPO4/C (x = 0.2, 0.5, and 0.8) samples show the presence of particles with a pseudo-spherical morphology (Figure 4) with nanocrystals of 40–50 nm. Notably, all the samples exhibit similar surface area and pore sizes.

Figure 3.A) XRD patterns of the LiFexMn1-xPO4/C (x = 0.2, 0.5, and 0.8) samples and XRD pattern of LiMnPO4 sample for comparison. B) Expanded 2θ region showing the continuous shift in the peak positions to the higher angles with the substitution of the Fe2+ for Mn2+.

Figure 4.FESEM images of A) LiFe0.2Mn0.8PO4/C, B) LiFe0.5Mn0.5PO4/C, and C) LiFe0.8Mn0.2PO4/C.

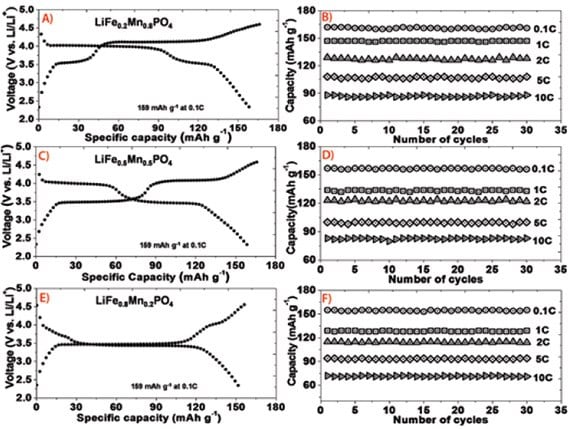

Figures 5A, 5C, and 5E illustrate the galvanostatic profiles of LiMn1-xFexPO4 (x = 0.2, 0.5, and 0.8) in which two distinct charge-discharge plateaus corresponding to Mn2+/Mn3+ and Fe2+/Fe3+ redox couples can be seen. All of the Mn-Fe mixed compositions exhibit a similar discharge capacity of 159 mAh g-1 at 0.1 C (close to the theoretical capacity of 170 mAh g-1) compared to nanostructured LiMnPO4 which delivers a capacity of 140 mAh g-1 at 0.05 C. Unlike LiMnPO4, the resultant capacity is an oxidation/reduction contribution of both Fe2+/Fe3+ (~3.45 V) and Mn2+/ Mn3+ (~4.1 V). Although the capacity is similar for all of the compositions, LiFe0.2Mn0.8PO4/C exhibits high energy density since 80% of the lithium storage capacity occurs at the higher potential Mn regime. The voltage polarization of mixed transition compositions is much lower than the parent LiMnPO4.13 The huge reduction in polarization at the Mn redox region and improved storage performance can be ascribed to nanostructuring, carbon coating, Fe-O-Mn superexchange interaction, lower activation energy, and the electronic configuration of Mn2+ (3d5) and Fe2+ (3d6) of Mn-Fe mixed olivines.

Figure 5.Galvanostatic charge/discharge profiles of LiFexMn1-xPO4/C (x = 0.2, 0.5, and 0.8) at 0.1 C and corresponding cycling stability up to 30 cycles at various C-rates: A,B) LiFe0.2Mn0.8PO4/C; C,D) LiFe0.5Mn0.5PO4/C; and E,F) LiFe0.8Mn0.2PO4/C, in a voltage window of 4.6–2.3 V at room temperature.

The stabilized discharge capacity of LiFexMn1-xPO4/C (x = 0.2, 0.5, and 0.8) at various C-rates (0.1, 1, 2, 5, and 10 C) are shown in Figures 5B, 5D, and 5F. The LiFe0.2Mn0.8PO4/C electrode delivers discharge capacities of 159, 141, 125, 106, and 88 mAh g-1 at 0.1, 1, 2, 5, and 10 C, respectively (Figure 5B). Similarly, the LiFe0.5Mn0.5PO4/C electrode exhibits discharge capacities of 159, 134, 122, 100, and 82 mAh g-1 at 0.1, 1, 2, 5, and 10 C, respectively (Figure 5D). LiFe0.8Mn0.2PO4/C electrode shows discharge capacities of 159, 126, 115, 93, and 70 mAh g-1 at 0.1, 1, 2, 5, and 10 C, respectively (Figure 5F). Nanostructured Mn-Fe mixed olivine samples showed good cyclic stability compared to nanostructured LMP/C of up to 30 cycles.13

Summary

Favorable physicochemical balancing can be achieved by nano-sizing and introducing conductive carbon wiring on the surface of nanomaterials. Nano-sized LMP/C exhibits superior storage performance of 140 mAh g-1 compared to a micron-sized LMP sample capable of only 43 mAh g-1 at 0.05 C. Use of the nanostructuring strategy with Fe2+ cation substitution at the Mn site enhances the electrochemical properties of the electrodes, resulting in improved energy storage capacity compared to nano-LMP/C. This makes them attractive as electrode materials for LIBs. Accordingly, nanostructured LiFexMn1-xPO4/C (x = 0.2, 0.5, and 0.8) compounds deliver a discharge capacity of ~159 mAhg-1 at 0.1 C.

Acknowledgments

Authors thank DSO, Singapore for their funding support (WBS:R-265-000-393-592).

Materials

References

To continue reading please sign in or create an account.

Don't Have An Account?