Preparing Self-Assembled Monolayers

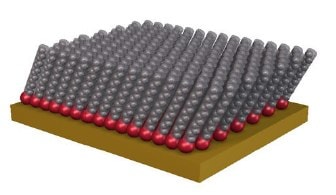

Figure 1.Schematic showing an ordered self-assembled monolayer of densely packed alkane thiols.

Although self-assembly takes place rapidly, good experimental procedures are needed to produce consistent, highly ordered films. This article outlines a recommended protocol for preparing SAMs.

Reagents and Equipment Recommended

- Gold coated substrates

- Thiol compound(s)

- 200 proof ethanol (Product No. 459844)

- Calibrated micropipettes

- Container for mixing thiol solution

- Tweezers for sample handling

- A dedicated ethanol solvent bottle

- Parafilm® sealing tape (Product No. P7793)

- Containers for sample preparation

- Petri dishes for transporting and storing SAMs

- Dry nitrogen gas

- Analytical Balance

- Sonicator

- pH paper

Precautions and Disclaimer

Please consult the Safety Data Sheet for information regarding hazards and safe handling practices.

Environment - A clean environment is key to preparing high-quality SAMs. Even low levels of contaminants can affect monolayer quality. Avoid rooms or hoods in which silanes or poly(dimethylsiloxane) (PDMS) have been used. These compounds easily cross contaminate a variety of surfaces. Iodine adsorbs readily onto gold and should also be avoided. All thiols should be handled in a fume hood.

Containers - Appropriate containers include glass or polypropylene (e.g., scintillation vials, polypropylene test tubes and centrifuge tubes). If glass containers are used, they must be cleaned thoroughly to avoid solution contamination.1 One option for glass cleaning is the use of piranha solution [30:70 v/v solution of 30% hydrogen peroxide (H2O2) and concentrated sulfuric acid (H2SO4)].

Note: Extreme caution must be taken when using piranha solution. It is a very strong oxidant and reacts violently with organic matter.

Containers should be easily sealable. For the highest quality films, oxygen exposure should be minimized during the assembly process. This is achieved by reducing the headspace above the thiol solution and backfilling with an inert gas. Each substrate is placed in its own container to avoid interactions that would be detrimental to film quality.

Containers can be reused, as long as they are rinsed well with solvent after each use and dedicated to the same thiol to avoid cross-contamination.

Solvent - For most thiols, 200 proof ethanol (Product No. 459844) is required for successful assembly.

Note: Elevated levels of copper disrupt the assembly of the thiols and may affect the performance of the resulting SAM.

Sample Slides – Gold-coated slides (Product No. 643246 and 643203) must have an adhesion layer of chromium (Cr) or titanium (Ti) under the gold layer. If this layer is missing, the gold will delaminate and ruin the monolayer during sonication.

Procedure

This procedure was adapted from an article in Material Matters™ Vol. 1 No. 2, written by Dr. Dan Graham from Asemblon and Dr. Sean Dingman from Sigma-Aldrich Corporation. It is appropriate for most thiols. Thiols containing amine or carboxy groups require slight modifications described in the procedure. The properties of PEG thiol monolayers depend on the method of self-assembly. Researchers should review the literature before using these materials.5–7

- Determine necessary amounts and concentration of thiol solution.

- Calculate the total volume of thiol solution needed to make the number of samples desired:

[Total volume of solution (mL)] = [total number of samples] × [Sample solution volume (mL)]. - Calculate the total amount of thiol needed to prepare desired amount of thiol solution.

[Mass of thiol (g)] = [Total Volume (mL)] × [C] × [10–6 mol/mL] × [MW (g/mol)]

Where MW is the Molecular Weight of the thiol, and C is the concentration in mM (typically 1–5 mM).

If the thiol is a liquid, convert the mass to a volume using the density. Use a calibrated micropipette to measure and dispense liquid thiols.

- Calculate the total volume of thiol solution needed to make the number of samples desired:

- Prepare Thiol Solution - Prepare enough solution for all samples to ensure the solution concentration is constant across the sample set. When preparing mixed thiol solutions, prepare a stock solution of each thiol separately, then mix them at the proper proportions for the final stock solution.

- Rinse all assembly containers with 3–5 mL of solvent. Repeat 2–3 times and re-cap each container. Also rinse all beakers, tweezers, etc., to be used in the experiment.

- Measure the appropriate volume of solvent into a clean solution container.

- Dispense the mass (or volume) of thiol into the solvent.

Note: If carboxy or amine terminated thiols are being used, adjust the pH of the thiol solution accordingly. For carboxyterminated thiols, adjust the pH to -2 by adding a few drops of concentrated HCl (Product No. 320331). For amine-terminated thiols, adjust the pH to -12 by adding concentrated NH4Cl (Product No. 213330) or triethylamine (Product No. T0886). - Sonicate solution for 5–10 minutes to dissolve.

- Once dissolved, dispense the planned volume of solution into each sample container.

- Sample Self-Assembly

- Immerse gold substrate in container containing thiol solution. Handle gold substrates with tweezers and minimize exposure to air.

- Backfill each container with dry nitrogen gas, seal the cap and wrap with Parafilm.

- Store the sample for 24–48 hours. Longer assembly times tend to result in better monolayer packing.

- Terminate Self-Assembly

Note: Functional groups on thiols can affect selfassembly termination.

- For simple alkane thiols, hold sample with clean tweezers and rinse with solvent for 10–15 seconds using a clean solvent bottle.

Note: For thiols with hydrogen-bonding, polar or bulky head groups, hold sample with clean tweezers and rinse with solvent for 10–15 seconds from a clean solvent bottle. - Dry sample with a stream of dry nitrogen gas.

- Place each sample in a container with fresh solvent and close the cap.

- Sonicate the samples for 1–3 minutes.

- Remove the samples individually and rinse again for 10–15 seconds under a steady stream of ethanol. At this stage no pH adjustment is necessary. Use pure solvent.

- Dry sample with a stream of dry nitrogen.

- For simple alkane thiols, hold sample with clean tweezers and rinse with solvent for 10–15 seconds using a clean solvent bottle.

- Sample Storage

- Place in clean Petri dish or desiccator.

- Backfill Petri dish with dry nitrogen.

- For long-term storage - Place Petri dishes in a jar backfilled with dry N2 and sealed with Parafilm. If you are going to use the monolayers for further experimentation, plan your experiments so you can rinse the samples right before use. Minimize time between preparation and use, since SAMs can oxidize over time.

Materials

References

如要继续阅读,请登录或创建帐户。

暂无帐户?