Detection, Measurement and Regulation of NOGE (Novolac Glycidyl Ethers) and Other Packaging-Derived Epoxy Compounds In Food Products

Analytical chemistry in food science

One of the most important areas of analytical chemistry is in food preparation, packaging, safety, regulatory compliance and related industries. Sigma-Aldrich has been a consistent and innovative supplier of standards, reagents, sample prep and chromatographic products for food analysis. This article discusses the background behind the recent addition of NOGE standards to our product portfolio.

Epoxy compound residues in food packaging

Many foods and food preservatives are acidic or have high salt concentration, naturally or to inhibit microbial growth. Both conditions are harsh on metal containers. To prevent corrosion, metal cans are usually coated on their interior surfaces. The socalled “organosol” coatings, of which PVC polymer forms the backbone, were developed to provide a flexible internal coating to prevent corrosion of metal cans. However, upon curing PVC produces HCl which can degrade the polymer coating. Epoxy compounds are added to the PVC polymer to act as HCl scavengers. One of the first such compounds used for this purpose is bisphenol-A-diglycidyl ether (BADGE). When analysts turned their attention to the fate of BADGE in the food, they found that the majority of the BADGE migrated from the coating and disappeared, presumably reacting with components of the food, a great cause for concern. Food packaging chemists, looking for alternatives to BADGE, began using the Novolac glycidyl ethers (NOGE). These, too, were found to migrate into the foods, but to different degrees in different foods compared to BADGE.

NOGE chemistry: A complex mixture of isomers and oligomers

Novolac is the technical name for complex mixtures obtained by reaction of phenol with formaldehyde under acidic conditions. When Novolac is reacted with epichlorohydrin, HCl is eliminated forming Novolac glycidyl ethers (NOGE). An important difference between NOGE and BADGE is the number of reaction products that are formed during the reaction between phenol and acetone or formaldehyde. Acetone reacts with phenol only at the para-position forming bisphenol-A, a single compound that is the precursor to BADGE. However, formaldehyde can react with phenol at the para and the two ortho sites creating three bisphenol-F isomers, the precursors to NOGE. Besides the three possible 2-ring bisphenol-F isomers, up to three phenols can be bonded to each phenol enabling oligomerization through the methylene groups. The result is that NOGE is a complex mixture of 2-, 3-, 4-, 5- and 6-ringed (and greater) compounds with various mean molecular weights. The three 2-ring NOGE compounds are called BFDGE (bisphenol-F-diglycidyl ether). An example of the formation of a 2-ring NOGE compound from bisphenol -F and epichlorohydrin appears in

Figure 1.

Figure 1.Example of the reaction of epichlorohydrin with a bisphenol-F isomer to form a 2-ring NOGE compound. NOGE compounds are a complex mixture containing 2-, 3-, 4-, 5- and 6-ring (and higher) structures. (Note: BFDGE cannot be directly produced as a pure compound.)

NOGE regulations

Although BADGE and NOGE (which includes BFDGE) have been used as additives for organosol coatings of metal cans, neither has been approved for this application. The European Food Safety Authority (EFSA) concluded that BADGE and its reaction products do not raise carcinogenicity and genotoxicity concerns, and has allocated a Tolerable Daily Intake for BADGE of 15 mg/kg per day. On the basis of the EFSA conclusions, draft Commission regulations would permit the continued use of BADGE subject to a specific migration limit of 9mg/kg of food or food simulants. However, the verdicts for BFDGE and NOGE were not as good. Because of structural indicators for toxic effects (epoxy groups and potential chlorohydrin formation) and the lack of both toxicological data and reliable analytical methods for their identification and quantification, the regulations banned the use of these substances in all but large food containers beginning January 1, 2005.

HPLC: addressing the analytical challenge of NOGE measurement

Two of the analytical challenges of NOGE analysis are (1) the extreme complexity of NOGE samples, and (2) previous lack of reliable analytical standards. Regarding the sample complexity, for 3-ring NOGES alone there are 135 possible NOGE compounds that are derived from the seven positional phenolic isomers. Considering there are 27 isomers of the 4-ring systems and the many more with the 5- and 6-ring systems, one can see how quickly the mixtures become extremely complex. Examples of some of the possible structures of a 3-ring NOGE compounds appear in Figure 2.

Figure 2.3-Ring NOGE Structures

Chromatography, especially HPLC, plays an important role in describing and measuring NOGE levels. When faced with the need to determine what NOGE compounds are present in a food sample and at what levels by HPLC, an analytical approach is to run calibration curves versus NOGE standards of known composition. NOGE standards are ideal for this application. The three modes of HPLC commonly used in NOGE analysis are SEC, RP- and NP-HPLC. Data on the sample from each technique, because of the different selectivity they provide, can be triangulated to give a clearer picture on the NOGE composition of the sample. SEC (size exclusion chromatography) provides group separation based on number of rings. It is often used as a preparative step to collect fractions relatively homogenous in ring number. These purified fractions are then reacted with water, HCl or acetic acid followed by reversed phase HPLC analysis, or acetylation followed by normal phase HPLC analysis. Both types of reactions open and modify the epoxy ring, and give more descriptive elution patterns. The acetylated compounds can also be analysed by GC or GC-MS. In all cases, it is critical to have reliable analytical NOGE standards to compare elution patterns, and an HPLC method that provides the maximum resolution of the complex mixture.

Standards and Supelco HPLC columns for reliable NOGE analysis

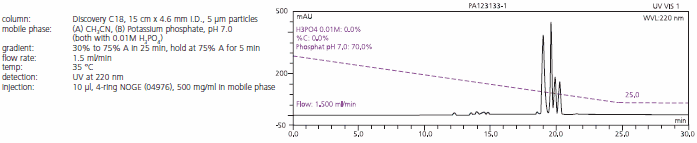

To help food analysts create the calibration curves necessary to characterize their samples, we offer unique BADGE, BFGDE and 3-, 4-, 5- and 6-ring NOGE analytical standards. Also, our Discovery and Ascentis lines of HPLC columns provide the high efficiency and selectivity required to resolve the complex mixtures of NOGE isomers and oligomers. An example of the HPLC analysis of our 4-ring NOGE standard (04976) on a Discovery® C18 HPLC column is shown in Figure 3.

Figure 3.QA chromatogram of 4-ring NOGE standard (04976) on a Discovery C18 column

Turn to Sigma-Aldrich when you need reliable, high quality standards, reagents, sample prep and chromatography products, tailored to meet the most current regulations in food, environmental, pharmaceutical and other areas of analytical chemistry. Our expert technical service is at your disposal to help you choose the right products and get the best results from your analysis.

For further reading:

Wagner, C.; Grob, K.; Biedermann, M.; Migration of Novolac Glycidyl Ether (NOGE) into Foods: Analytical Problems. Mitt. Lebensm. Hyg. 2000, 91, 146–157.

Biedermann, M.; Wagner, C.; Grob, K.; Imhof, D.; Beuggert, H.; Bisphenol-A-Diglycidyl Ether (BADGE) and Novolac Glycidyl Ether (NOGE) as Additives in Can Coatings. Mitt. Lebensm. Hyg. 2000, 91, 274–286.

Materials

如要继续阅读,请登录或创建帐户。

暂无帐户?