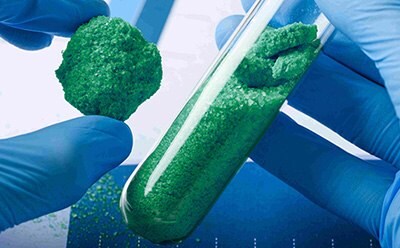

Selection Guide: High-Purity Metal Salts for the Synthesis of Cathode Active Materials (CAM)

Introduction

Cathode Active Materials (CAM) are vital for lithium-ion battery performance, influencing energy density, cycle life, safety, and cost. Choosing high-purity salt precursors is critical to achieving optimal material purity, morphology, and phase formation, which directly determine battery efficiency and longevity. This guide helps users identify the best salt precursors for their preferred synthesis routes and CAM characteristics, supporting advanced battery performance for electric vehicles and renewable energy storage. These synthesis types include:

- Co-precipitation

- Sol-gel

- Hydrothermal

- Spray pyrolysis

- Solid state

- Combustion

- Emulsion drying

- Solvothermal

- Pichini method

- RAPET method

CAMs serve as the host for lithium ions during operation, and their composition, crystallinity, and particle morphology govern electrochemical behavior and durability. Selecting precursor salts with appropriate purity and chemical properties ensures uniform cation distribution, minimizes defects, and enhances lithium-ion mobility, key factors for high capacity and stable cycling.1-3

Precursor Properties Driving Battery Performance

Purity: Trace metal impurities adversely affect crystal lattice integrity, phase purity, and particle morphology, which directly degrade ionic conductivity, capacity, rate capability, and cycling stability in batteries. Careful control of precursor purity is essential to optimize CAM synthesis and ensure high battery performance.4, 15, 16

Recommendation: Use high-purity salts (≥99.9%) to minimize adverse impurities. These salts have been specifically developed through a multi-step purification process to minimize 32 -68 trace metal impurities to ppm levels, ensuring the quality you need for optimal material development.

Practical Tips and FAQs

- Use Merck high-purity salts (≥99.9%) certified with 32-68 trace metal data sheets for assured quality

- Store salts in airtight, moisture-free containers to prevent hydrolysis and contamination, which can alter precursor chemistry and affect phase formation during synthesis

- Choose salts with decomposition temperatures aligned to your calcination schedule to enable gradual, controlled phase formation and minimize unwanted secondary phases

- Maintain consistent pH and precursor concentrations in in coprecipitation to achieve uniform particle size and stoichiometry, minimizing cation mixing and enhancing lithium-ion mobility

Frequently Asked Questions (FAQs)

Q1: Why is high purity important for CAM precursors?

A: High purity minimizes harmful impurities that create defects and secondary phases, which degrade ionic conductivity, capacity, and cycle life. Using certified high-purity salts ensures consistent electrochemical performance.

Q2: Can I use lower-cost technical grade salts?

A: Lower-grade salts often contain metal impurities (Fe, Al, Cu) that lead to poor crystal integrity and rapid capacity fade. Investing in high-purity salts reduces synthesis failures and improves battery reliability.

Q3: How does precursor thermal stability affect the final CAM?

A: Salt precursors with appropriate decomposition temperatures enable controlled crystal growth and phase purity, leading to better cycling stability and capacity retention

Q4: How to prevent cation mixing during synthesis?

A: Precise control of precursor stoichiometry, pH, and the use of high-purity salts reduce cation disorder. Uniform nucleation and controlled growth from quality precursors enhance structural stability.

References

To continue reading please sign in or create an account.

Don't Have An Account?