Flavor & Fragrance Analysis

Flavor and fragrance formulations are essential additions to various foods and beverages, cosmetics, pharmaceuticals, personal care, and home care products. These formulations can be either single compounds or a mixture of small chemical compounds, carefully selected to enhance the overall taste and scent of a product. Natural flavors and fragrances are obtained from plant material or animal products. On the other hand, artificial flavors and fragrances are synthesized in a laboratory, utilizing molecules that can be chemically identical to those derived from natural sources.

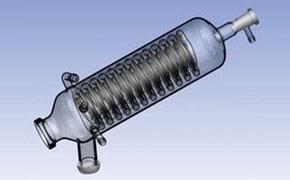

Flavor and fragrance ingredients are chemical compounds, either obtained naturally through distillation, fermentation, or extraction techniques or through chemical synthesis and biotechnology using genetically engineered microbes. Once obtained, these ingredients are typically blended together in specific formulations to create a desired flavor or fragrance profile for a variety of consumer goods and products.

Your Solvent Source: Find the right fit with Supelco®, Sigma-Aldrich®, & SAFC® brands, covering analytical, lab, & biopharmaceutical uses. Order online.

Achieve precise separations with our extensive HPLC column collection. Enhance retention, resolution, and selectivity.

Aldrich® chemistry glassware offers a full range of standard beakers, flasks, tubing, reaction vessels, chromatography columns and custom glassblowing services.

Explore our extensive collection of chemical reference standards for chromatography, spectroscopy, and analysis needs.

Irrespective of their source of origin, the flavor and fragrance compounds are regulated by various governmental bodies, such as the Food and Drug Administration (FDA) and the International Fragrance Association (IFRA). The goal of these regulations is to ensure that the fragrance and flavor chemicals are safe for use in consumer products and do not pose a threat to public health.

Fragrance and flavor analysis identifies and characterizes the chemical components responsible for the taste and odor of various substances. The fragrance and flavor profile analysis uses techniques such as gas chromatography, mass spectrometry, and sensory evaluation. Specially trained scientists, known as flavorists or perfumers, use this information to create new products with specific flavor and fragrance characteristics. It is an important area of research in the food and beverage, cosmetics, and personal care industries in product development. Flavor and fragrance analysis is also used in quality control and product testing. By analyzing the flavor and aroma profiles of finished products, companies can ensure that their products are consistent and meet the expectations of consumers.

Sustainability in the Flavor and Fragrance Industry

Apart from the quality of fragrance and flavor ingredients, there has been a growing interest among consumers in knowing the origin of the ingredients used in their products and the sustainability of the methods employed by companies to produce these ingredients. In the flavor and fragrance industry, sustainability encompasses a comprehensive approach that considers the environmental, social, and economic effects of production and consumption. It involves a multifaceted approach that considers the entire lifecycle of products, from responsible sourcing and production to reducing environmental impact, ensuring product safety, and sustainable packaging.

Visit our document search for data sheets, certificates and technical documentation.

Related Articles

- Navigate global natural flavor regulations and complexities of sourcing and manufacturing with regional insights. Understand classifications and limitations.

- A white paper explaining the complexities of Kosher Ingredients, Benefits for the Food Industry, Considerations for Kosher Certification.

- Vanilla Regulations – The Law and the Labeling of the World’s Most Popular Flavor

- Food allergens are well known and codified by most global food regulatory agencies. Regulators and consumers require that food allergens be clearly displayed on packages.

- A review of food and fragrance contamination by allergens and the next steps for industry response.

- See All (18)

Find More Articles and Protocols

How Can We Help

In case of any questions, please submit a customer support request

or talk to our customer service team:

Email custserv@sial.com

or call +1 (800) 244-1173

Additional Support

- Chromatogram Search

Use the Chromatogram Search to identify unknown compounds in your sample.

- Calculators & Apps

Web Toolbox - science research tools and resources for analytical chemistry, life science, chemical synthesis and materials science.

- Customer Support Request

Customer support including help with orders, products, accounts, and website technical issues.

- FAQ

Explore our Frequently Asked Questions for answers to commonly asked questions about our products and services.

To continue reading please sign in or create an account.

Don't Have An Account?