Glycol Ethers Properties & Examples, Organic Solvents

Introduction

Glycol ethers, with both an ether and alcohol functional group in the same molecule, are one of the most versatile classes of organic solvents. The product line consists of more than 10 distinct chemicals.

The Dow Chemical Company is the world’s leading producer of ethylene-oxide-based glycol ethers, both in product-line breadth and total volume produced. Most importantly, Dow is the world’s leading producer of many of the principal raw materials used to manufacture glycol ethers: ethanol, n-propanol, n-butanol and ethylene oxide.

DOW Glycol Ether products, as well as the materials to manufacture them, are produced to exacting standards.

Chemistry

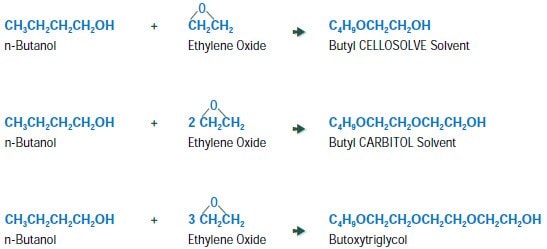

DOW Glycol Ether products are produced through continuous processes of selectively reacting an alcohol and ethylene oxide. The butyl glycol ether family illustrated below is typical of the product family created with each of the chosen alcohols.

Butyl glycol ether family

Glycol ethers, as a class of chemicals having longer hydrocarbon-like alkoxide groups, display solubility more characteristic of hydrocarbons. Thus, glycol ethers produced from higher molecular weight alcohols, such as Hexyl CELLOSOLVE™ solvent, have limited water solubility. The ether groups introduce additional sites for hydrogen bonding with improved hydrophilic solubility performance.

Applications

Solvency Properties

Glycol ethers are characterized by their excellent solvency, chemical stability and compatibility with water and a number of organic solvents. The dual functionality present in the CELLOSOLVE and CARBITOL™ solvents and the alkoxytriglycol glycol ethers accounts for their unique solvency properties. As a class of products, CELLOSOLVE and CARBITOL solvents are:

- Mild-odored solvents for many resins, oils, waxes, fats and dyestuffs

- Coupling agents for many water/organic systems

- Miscible with a wide range of polar and non-polar organic solvents

- Miscible with water in most cases

End-Uses

This strong solvency leads to the selection of certain CELLOSOLVE and CARBITOL solvents and the alkoxytriglycol glycol ethers for a broad array of end-uses:

- Dye solvents in the textile, leather and printing industries

- Solvents for grease and grime in industrial cleaning and specialty formulations

- Solvents for insecticides and herbicides for agricultural applications

- Coupling solvents for hard-surface cleaners and other soap-hydrocarbon systems

- Solvents and cosolvents for conventional lacquer, enamel and stains for industrial coating systems

- Cosolvents for waterborne industrial coating systems

- Fuel System Icing Inhibitor (FSII)

- Freeze-thaw agents in aqueous systems

- Chemical reaction solvents

Chemical Intermediates

Members of the CELLOSOLVE and CARBITOL solvent families are also useful chemical intermediates. These glycol ethers will undergo many of the same reactions as alcohols because they contain the hydroxyl (-OH) functional group. Some typical examples are:

- Reaction with carboxylic acids, carboxylic acid chlorides, anhydrides and inorganic acids to produce esters

- Reaction with organic halides to produce ethers, such as glymes

- Reaction with alkenes and alkynes to produce ethers

- Reaction with halogenating agents to produce alkoxy alkyl halides

- Reaction with epoxides to produce polyether alcohols

- Reaction with aldehydes and ketones to produce hemiacetals and acetals

Product Profiles

Propyl CELLOSOLVE Solvent (Ethylene Glycol Monopropyl Ether)

C3H7OCH2CH2OH

Propyl CELLOSOLVE solvent is useful in printing and other specialized coatings applications.

Butyl CELLOSOLVE Solvent (Ethylene Glycol Monobutyl Ether)

C4H9OCH2CH2OH

Butyl CELLOSOLVE solvent is an excellent solvent widely used in coatings and cleaner applications, including many directed to consumer markets.

Butyl CELLOSOLVE solvent offers superior performance in many hard-surface cleaners and related cleaning formulations. Mineral oils, water and soaps are miscible with Butyl CELLOSOLVE solvent. Accordingly, this product is widely employed as a coupling agent to stabilize immiscible ingredients in industrial metal cleaners, in vapor degreasers, in the clarification of oil-water dispersions, and in the formulation of concentrated liquid cleaners. In fabric cleaners, Butyl CELLOSOLVE solvent assists in removing water-soluble stains and aids in brightening the colors of garments. It improves penetrating and wetting action of phosphoric acid-type rust removers.

Butyl CELLOSOLVE solvent exhibits strong solvency for alkyd, phenolic, nitrocellulose and maleic-modified resins. It strengthens blush resistance and is one of the best retarders for nitrocellulose lacquers. Butyl CELLOSOLVE solvent heightens gloss, improves flow-out and prevents orange-peel formation in lacquers, conventional and high solid coatings. Related applications include special coatings for polystyrene, epoxy coatings and high-low thinners for viscosity reduction of alkyd baking enamels. In addition, Butyl CELLOSOLVE solvent is the most widely used cosolvent for industrial waterborne coatings due to its excellent balance of volatility, resin solvency and oil/water solubility.

Butyl CELLOSOLVE solvent is a recognized inert formulating aid for the compounding of some insecticides and herbicides.

Hexyl CELLOSOLVE Solvent (Ethylene Glycol Monohexyl Ether)

C6H13OCH2CH2OH

Hexyl CELLOSOLVE solvent is a high boiling point, slow evaporating solvent with excellent solvency characteristics. It may be used to coalesce waterborne latex coatings and to balance solvency and volatility in high solids coatings.

Hexyl CELLOSOLVE solvent has the characteristic structure of glycol ethers and contains both ether and alcohol functional groups in the same molecule. As a result, it provides unique cleaning power for removal of both watersoluble and greasy (water-insoluble) soils. The linear hexyl portion of Hexyl CELLOSOLVE solvent provides excellent oil solubility characteristics that make it useful in both consumer and industrial cleaner applications.

Hexyl CELLOSOLVE solvent plays an important role in specialty printing inks. Because of its limited water solubility and slow evaporation, it can be used in formulations for the silk screen process to prevent premature setting of the ink.

Methyl CARBITOL Solvent (Diethylene Glycol Monomethyl Ether)

CH3(OCH2CH2)2OH

Methyl CARBITOL solvent offers both excellent solvency and low volatility. The product’s mild odor and ability to improve dye penetration make it attractive for non-grain-raising wood stains, spirit-type dyes and textile dye pastes. Methyl CARBITOL solvent is suitable for dyes, oils, fats, waxes and resins. It is also a coalescing aid for polyvinyl acetate latexes. Methyl CARBITOL Solvent-Fuel System Icing Inhibitor (FSII) is used by the aviation industry according to U. S. Military Specification MIL-I-85470 and equivalents around the world to prevent icing in aircraft jet fuel systems.

CARBITOL Solvent (Diethylene Glycol Monoethyl Ether)

C2H5(OCH2CH2)2OH

CARBITOL solvent is an important solvent in non-grain-raising wood stains and serves as a component of industrial cleaners.

Textile printing and dyeing processes utilize CARBITOL solvent to facilitate penetration into fibers and to promote the production of intense, bright shades. These characteristics, as well as its high boiling point and low vapor pressure, make it useful for twist setting and yarn and cloth conditioning.

Mineral oil-soap and mineral oil-sulfonated oil mixtures require fast-acting mutual solvents. Small quantities of CARBITOL solvent in these mixtures form translucent-to-clear dispersions, in contrast to the usual turbid dispersion that indicates incomplete solubility.

Butyl CARBITOL Solvent (Diethylene Glycol Monobutyl Ether)

C4H9(OCH2CH2)2OH

Butyl CARBITOL solvent is useful in lacquers, dopes and stamp-pad and printing inks that require a solvent with an extremely low rate of evaporation. This glycol ether is incorporated in high-bake enamels to contribute desirable flow and gloss characteristics. Butyl CARBITOL solvent is a dye solvent used to promote rapid and uniform ink penetration for printing box-board and similar materials.

Butyl CARBITOL solvent serves as a mutual solvent for soaps, oils and water and as a component of liquid cleaners, “soluble” oils and textile oils. It has found increased use in cleaning formulations because of its good solvency for greasy soils and waxes.

Butyl CARBITOL solvent is used as a solvent in formulating aids for latex paints and as a dispersant for vinyl chloride resins used in organosols. It is a diluent for hydraulic brake fluids and an intermediate in the manufacture of plasticizers.

Hexyl CARBITOL Solvent (Diethylene Glycol Monohexyl Ether)

C6H13(OCH2CH2)2OH

Hexyl CARBITOL solvent, like Hexyl CELLOSOLVE solvent, displays a strong hydrocarbon-type solvency. The increased ether functionality of Hexyl CARBITOL solvent provides greater solubility with water than Hexyl CELLOSOLVE solvent.

Hexyl CARBITOL solvent is useful as a coalescing aid in waterborne emulsion or dispersion coatings. It is a slow evaporating solvent that partitions primarily into the polymer phase of a waterborne coating and reduces Minimum Filming Temperature. It can be used with associative thickeners to enhance application properties such as brushability or roll application in high performance coatings.

Due to its slow evaporation and excellent solvency characteristics, Hexyl CARBITOL solvent contributes good flow and leveling to high solids coatings during the drying/curing cycle. It is extremely important that the last solvent to evaporate has good solvency properties for the coating system. This allows uniform diffusion of the solvent through the film and maximizes appearance and film properties by reducing the occurrence of defects due to solvent-pop and air entrapment.

Hexyl CARBITOL solvent has shown excellent performance in cleaning formulation for the removal of greasy soils.

Hexyl CARBITOL solvent is used in metal deco inks as a slow evaporating solvent providing good flow and leveling.

Alkoxytriglycols

Methoxytriglycol (Triethylene Glycol Monomethyl Ether)

CH3(OCH2CH2)3OH

Ethoxytriglycol (Triethylene Glycol Monoethyl Ether)

C2H5(OCH2CH2)3OH

Butoxytriglycol (Triethylene Glycol Monobutyl Ether)

C4H9(OCH2CH2)3OH

The alkoxytriglycols are useful as low-volatility components in paint stripping formulations, as dye carriers for textile dye processes, as chemical process solvents and as intermediates for making esters for use as solvents, surfactants and plasticizers. The alkoxytriglycols are also useful as components of high boiling hydraulic brake fluids.

(1) Pensky-Martens Closed Cup unless otherwise noted.

(2) Pour Point.

(3) Decomposes at 760 mmHg, boiling point extrapolated.

† The physical property data listed are considered to be typical properties, not specifications.

† The physical property data listed are considered to be typical properties, not specifications.

(1) Percent by weight; 25% Product: 75% water.

(2) Percent by weight; 90% Hexyl CELLOSOLVE solvent: 10% water (solubility limitations).

(3) Percent by weight; 75% Hexyl CARBITOL solvent: 25% water (solubility limitations).

† The physical property data listed are considered to be typical properties, not specifications.

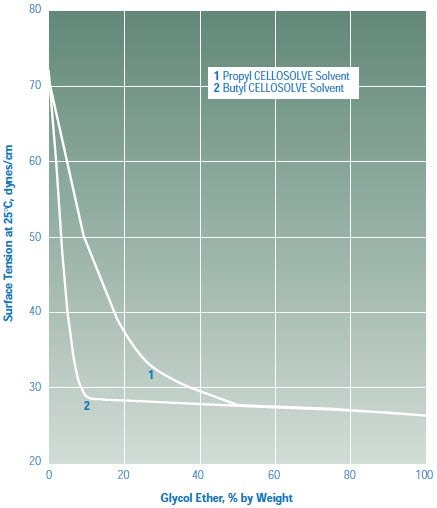

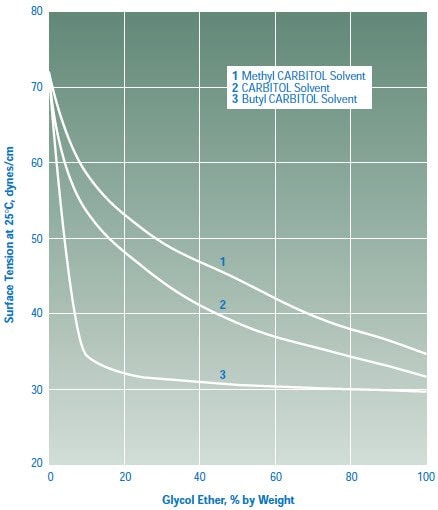

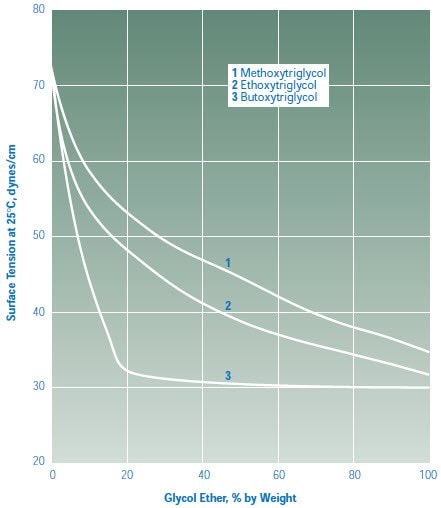

Surface Tension

Figure 1.Surface Tension of Aqueous Solutions for Selected CELLOSOLVE Solvents

Figure 2.Surface Tension of Aqueous Solutions for Selected CARBITOL Solvents

Figure 3.Surface Tension of Aqueous Solutions for Selected Alkoxytriglycols

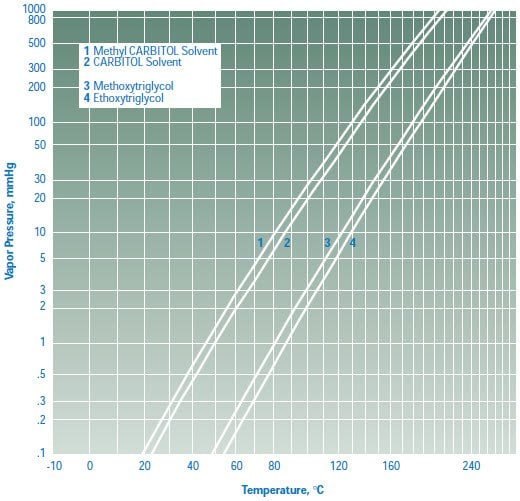

Figure 4.Vapor Pressures for Selected Methyl and Ethyl Glycol Ethers

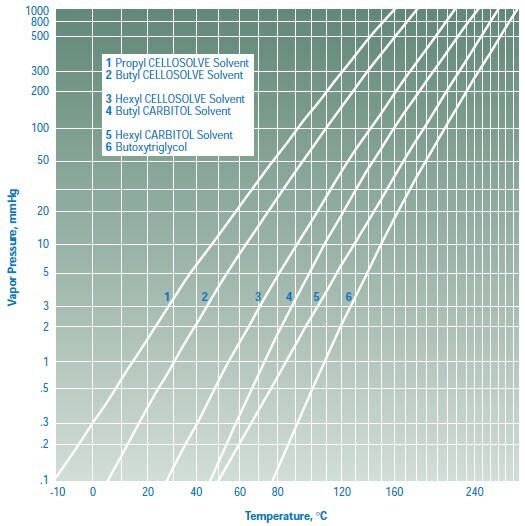

Figure 5.Vapor Pressures for Selected Propyl, Butyl & Hexyl Glycol Ethers

Inverse Solubility

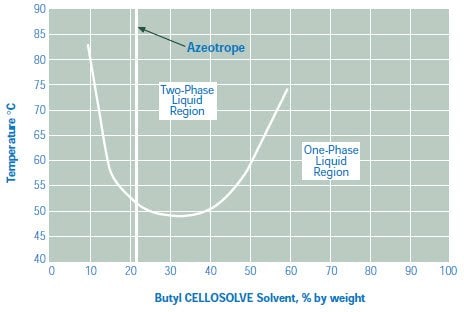

Some glycol ethers exhibit an inverse solubility in water at elevated temperatures. For example, Butyl CELLOSOLVE solvent becomes less soluble and separates from solution as the solution temperature is increased (Figure 6). This feature can be used to enhance the solvent effect of Butyl CELLOSOLVE solvent in aqueous solutions. In some cases, this process can be utilized to remove Butyl CELLOSOLVE solvent from an aqueous waste stream. At temperatures above 50 °C, it may be possible to decant an aqueous layer from an upper organic layer, thus reducing the organic content of the aqueous waste stream.

Figure 6.Mutual Solubility of Butyl CELLOSOLVE Solvent/Water vs. Temperature

Storage & Handling

DOW Glycol Ether products can be stored and piped in carbon steel. Stainless steel or high baked, phenolic-lined tanks may be used for critical applications sensitive to slight discoloration or trace-iron contamination. A centrifugal pump is suitable for transfer services. Butyl rubber or EPDM can be used for gaskets and packing.

NOTE: Dow does not recommend using aluminum, copper, galvanized iron, galvanized steel, Viton elastomers, neoprene or natural rubber with its glycol ethers.

DOW Glycol Ether products do not present a significant flammability hazard. They have relatively low vapor pressures.

Glycol ethers have relatively low viscosities and freezing points. Heated storage is not normally required. Ethoxytriglycol is a possible exception, since it freezes at -9°F (-23 °C).

Glycol ethers are quite stable when proper handling and storage conditions are employed. In long-term storage, nitrogen-blanketing of tanks may be desired to pre-empt any tendency of the glycol ethers to oxidize, which shows itself as an increase in acidity. Additionally, an appropriate desiccant system may be chosen to prevent moisture pickup during storage or turnover of the tank contents.

The recommended resample times for glycol ethers are 24 months for drums, 12 months for bulk and 6 months for samples. After this time, material should be sampled and tests run to be sure that quality has been maintained. After the original test time, each retest should be one-half the original period.

Shipping Data

The size of the shipment, mode of transportation and latest regulations all affect shipping classifications. Consult the U.S. Department of Transportation Shipping Manual. Shipment of these products must comply with all applicable Federal, state and local regulations.

Environmental Effects

Dow has carried out a series of laboratory studies on the biodegradation and ecological effects of its glycol ethers. Biodegradation testing was conducted following methods published by the Environmental Protection Agency (EPA)(1) and Organization for Economic Cooperation and Development (OECD)(2). Based on the results of these tests (Table 3), the DOW Glycol Ether products, as a group, demonstrate excellent biodegradability characteristics. All of the DOW Glycol Ether products with the exception of butoxyglycol would be classified as “readily”/rapidly biodegradable and would not be expected to persist in the natural environment for a significant period of time.

Bacterial growth inhibition tests(3) indicate that none of the DOW Glycol Ether products should be inhibitory to conventional biological wastewater treatment processes at reasonable discharge levels [500 to 1000 mg/L in compliance with applicable regulations], and they would be expected to undergo rapid biodegradation in the concentrated biomass of these systems.

Aquatic toxicity measurements show effects ranging from slightly toxic to relatively nontoxic with tested species, which included fathead minnows and Daphnia Magna. Most tested glycol ethers show LC50 / EC50 values above 1000 mg/L. These tests were conducted by procedures that follow EPA(4,5,6)/ASTM(7)/ OECD(8) techniques.

(1) Fate, Transport, and Transformation Test Guidelines, OPPTS 835.3110, Ready Biodegradability, EPA 712-C-98-076, January 1998.

(2) OECD Guidelines for Testing of Chemicals, Organization for Economic Cooperation and Development, Vol. 2, Section 3, Degradation and Accumulation, Updated 1993.

(3) Alsop, G. M., R. A. Conway, “Bacterial Growth Inhibition Test,” Journal Water Pollution Control Federation, Vol. 52, No.10, October 1980.

(4) Methods for Measuring the Acute Toxicity of Effluents to Freshwater and Marine Organisms, EPA/600/4-85/O1 3, March 1985

(5) EPA, CFR 797.1400, Fish Acute Toxicity Test, February 1997.

(6) EPA, CFR 797.1300, Daphnid Acute Toxicity Test, February 1997.

(7) Annual Book of ASTM Standards, Water and Environmental Technology, Vol.11.05, (1995).

(8) OECD Guidelines for Testing of Chemicals, Organization for Economic Cooperation and Development, Vol. 1, Section 2, “Effects On Biotic Systems,” Updated 1993.

(1) This test method monitors carbon dioxide produced from the biooxidation of molecular carbon in the test substance. Biodegradation is the percent ratio of evolved CO2 to maximum theoretical CO2, based on organic carbon content of the test substance.

(2) The material meets the criteria if it passes from 10% biodegradable to 60% biodegradable within a 10-day period.

(1) Calculated theoretical oxygen demand (THOD) based on complete oxidation of the chemical to carbon dioxide and water. Measured value determined by chemical oxygen demand procedure published in Standard Methods for the Examination of Water and Wastewater, 18th ed, Am Public Health Assoc., Washington, DC (1992).

(2) Determined by turbidity/growth procedures where the median inhibition concentration (IC50) is measured after 16 hours of incubation with sewage microorganisms.

(3) EPA/ASTM bioassay procedures were followed in obtaining these values. Ten test organisms were used per test concentrations.

FDA Status

Certain glycol ethers are presently cleared under regulations of the United States Food and Drug Administration (FDA) for use in food-related applications.

Glycol ethers may be used in any food-related application (such as coatings or printing inks) without regard to specific FDA regulations if subsequent processing steps, such as washing, drying, vaporizing, heating, purging, etc., are adequate to completely remove all traces of the solvent. Such treatments should remove solvent residues that could be considered food additives. If there are no residues that can be considered as additives under these conditions, FDA regulations are not applicable.

EPA Status

Several glycol ethers have been cleared by the Environmental Protection Agency (EPA) for use as inert ingredients in pesticide formulations under EPA Regulation 40 CFR 180.1001.

(1) This EPA Regulation cross-references to FDA Regulation 182.99 and 582.99 (21 CFR).

(2) Included in EPA list of Potentially Toxic Inerts/High Priority for Testing (ibid.). No specific requirements for continued use, but EPA may issue data call-ins for toxicology data.

Product Safety

The product family of glycol ethers has been the object of a substantial body of toxicological testing. Significant differences exist in product toxicity and corresponding exposure levels considered appropriate for different products within the family. For several of the products, special Health Effects Overviews and Toxicology Summaries have been prepared.

When considering the use of any Dow products in a particular application, you should review Dow’s latest Material Safety Data Sheets and ensure that the use you intend can be accomplished safely. For Material Safety Data Sheets and other product safety information, contact. Before handling any other products mentioned in the text, you should obtain available product safety information and take necessary steps to ensure safety of use.

No chemical should be used as or in a food, drug, medical device, or cosmetic, or in a product or process in which it may contact a food, drug, medical device or cosmetic until the user has determined the suitability and legality of the use. Since government regulations and use conditions are subject to change, it is the user’s responsibility to determine that this information is appropriate and suitable under current, applicable laws and regulations.

Dow requests that the customer read, understand, and comply with the information contained in this publication and the current Material Safety Data Sheet(s). The customer should furnish the information in this publication to its employees, contractors, and customers, or any other users of the product(s), and request that they do the same.

Technical Service

For technical assistance concerning DOW glycol ether products, contact us.

如要继续阅读,请登录或创建帐户。

暂无帐户?