Real-time Monitoring of Solvent Removal in ADC Manufacturing

The linkers that connect the targeting antibody and the small molecule drug payload in an antibody-drug conjugate (ADC) are typically highly hydrophobic molecules. These linkers require a specific solvent, such as dimethyl sulfoxide (DMSO), dimethylacetamide (DMAc), or dimethylformamide (DMF), at a concentration commonly ranging from 10 to 20% (V/V), for solubilization.

Removal of residual solvents from the ADC manufacturing process is essential to ensure product quality and safety. Tangential flow filtration (TFF) or other separation approaches can be used to meet the International Council for Harmonization (ICH) Q3C R91 guidelines related to solvents. This page describes the use of Raman spectroscopy for fast, in-line, real-time monitoring of DMSO removal during ADC manufacturing.

ADC Solvent Removal Workflow

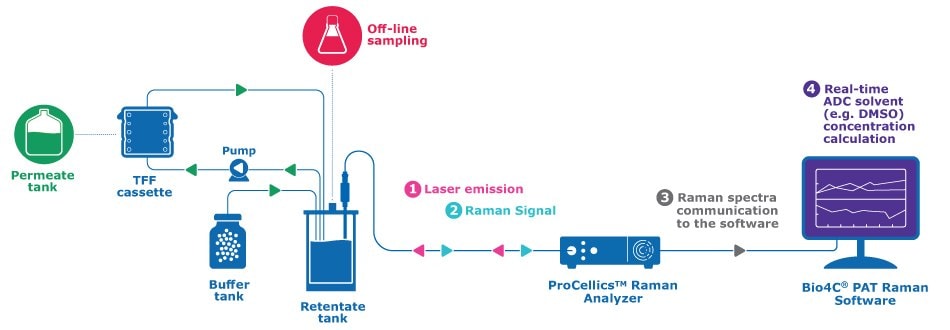

DMSO removal from a crude ADC was performed using a TFF system consisting of three Pellicon® 3 Cassettes with 30 kDa Ultracel® membranes and C screen. Each device had an effective membrane area of 88 cm2 for a total area of 264 cm2. Devices were installed in a Pellicon® Mini Holder (Figure 1).

Figure 1.Experimental TFF step-up for DMSO removal in ADC production.

The operating conditions for the TFF process are provided in Table 1. The crude ADC was fed into the TFF system for the diafiltration process and recirculated through the system while a diafiltration buffer was fed into the retentate tank to maintain a constant volume (diafiltration constant volume). DMSO sieved through the membrane to the permeate while the ADC was retained by the membrane in the retentate. Throughout the diafiltration process, DMSO was gradually removed from the recirculated system and collected in the permeate vessel.

Set-Up of the Raman Spectroscopy Analyzer and Connection to PAT Software

The ProCellics™ Raman Analyzer probe (785 nm) was set up to collect spectra from the retentate tank; Bio4C® PAT Raman Software was used for real-time measurement of DMSO removal. A Raman spectrum was acquired every 2.5 minutes.

The analytical calibration method for DMSO quantitation using the ProCellics™ Raman Analyzer was built using the Bio4C® PAT Chemometric Expert Module. Raman spectra were pre-processed, and a partial least squares (PLS) method was used to obtain the DMSO calibration. The Raman method was based on the optimization of the following main statistical criteria:

- Cumulative explained variance (R²)

- Cumulative predicted variance (Q²)

- The Root Mean Square Error of Calibration, Cross-validation, and Prediction (RMSEC, RMSECV, and RMSEP).

An off-line sampling device was also set up on the retentate tank to collect 0.5 mL samples every 5 minutes. The off-line DMSO concentration was obtained using high-performance liquid chromatography (HPLC) analysis.

Correlation Between DMSO Concentration and Raman Spectra

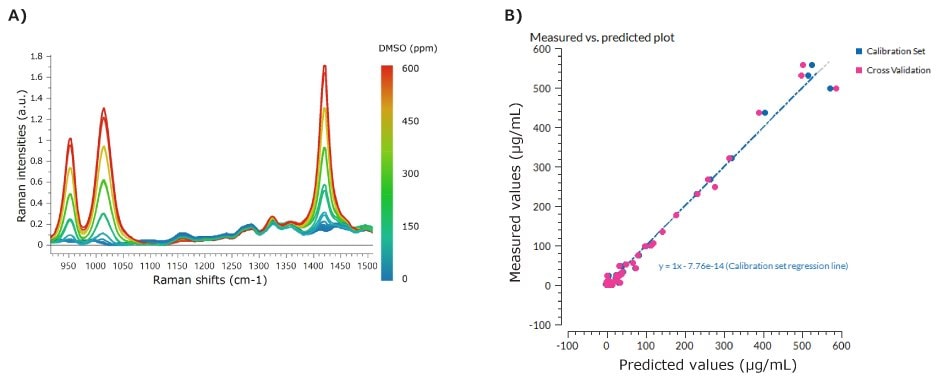

The correlation between the DMSO concentration and the Raman spectra is shown as an increase in specific peaks in the retentate tank over the process time (Figure 2A).

Two DMSO calibration methods were built based on the PLS chemometric approach; one method was for the entire DMSO concentration range, and the second (Figure 2 and Table 2) was for a lower concentration range to ensure accuracy in the low concentration range to comply with the regulatory Limit of Detection (LOD). The results focused on the low concentration range, which is the most challenging and relevant to meet regulatory guidelines.

Figure 2B shows very good linearity between the off-line analytical method and the Raman estimations, both in calibration and cross-validation. Table 2 summarizes the calibration performance and shows excellent accuracy according to the R², Q², RMSEC and RMSECV indicators.

Figure 2.(A) Pre-processed spectra at different DMSO concentrations (standard normal variate SNV with baseline correction); (B)Measured vs. predicted plot of calibration (μg/mL).

Real-Time Monitoring of TFF in ADC Manufacturing Using Raman Spectroscopy

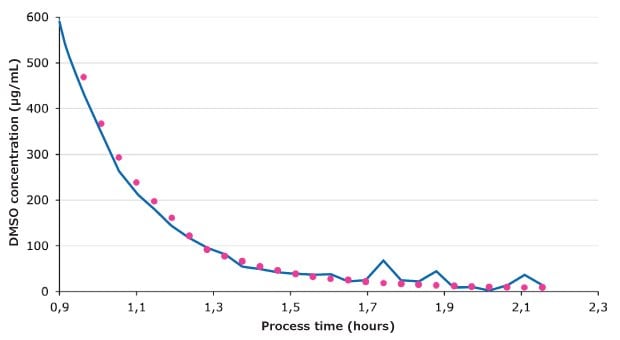

To further validate the accuracy of the ProCellics™ Raman Analyzer for monitoring solvent removal, in-line and real-time monitoring of the TFF process for DMSO clearance was performed. The Raman measurements were compared with the off-line reference measurements (Figure 3).

The RMSEP and the relative error (%) on the maximum value were used to evaluate the accuracy of the Raman calibration method (Table 3).

Figure 3.Comparison of off-line measurements and real-time monitoring predicted values obtained by the ProCellics™ Raman Analyzer with Bio4C® PAT Raman Software for DMSO across the range below 500 μg/mL.

The ProCellics™ Raman Analyzer accurately quantified the DMSO concentration below 100 μg/mL, down to a concentration of approximately 20 to 50 μg/mL (Figure 3). As shown in Table 3, an RMSEP of 22 μg/mL was obtained for real-time monitoring. This validation error was equal to the RMSECV obtained during model building, which shows the robustness of Raman spectroscopy in monitoring the process step.

The ProCellics™ Raman Analyzer provided satisfactory accuracy for the lower concentrations, in compliance with regulatory guidelines1. These results show that Raman can be used as an analytical method of reference for in-line and real-time monitoring of DMSO clearance during the TFF process of ADC formulation during process development and manufacturing.

Conclusion

Raman spectroscopy enables in-line, real-time monitoring of the DMSO removal process during the TFF step in ADC production. The ProCellics™ Raman Analyzer accurately monitored the concentration of DMSO to below 100 ppm (20 mg/mL of ADC product).

Consequently, Raman spectroscopy can support process optimization efforts by providing insights into the kinetics and efficiency of DMSO removal during TFF and critical process parameters such as transmembrane pressure, flow rate, and diafiltration endpoints. This approach minimizes the need for sampling and contributes to safe working conditions during ADC production as it reduces the risk of contamination and protects against exposure to the highly potent ADC molecules.

To request individualized support from our team, please reach out through our contact form. Upon submission, a technical expert will be in touch with you promptly.

Related Products

References

如要继续阅读,请登录或创建帐户。

暂无帐户?