Viral Safety in Bioprocessing

Bioprocessing uses animal-derived cells to produce therapeutics such as monoclonal antibodies or recombinant proteins. As production templates depend on cell culture, they’re susceptible to contamination by bacteria and viruses. Drug manufacturers need to ensure the drug product is free of these contaminants and safe for administration to patients.

Section Overview

- Where Does Viral Contamination Come From?

- Mitigating the Risk of Viral Contamination

- Preventing Upstream Viral Contamination

- Detecting Viral Contaminants Throughout the Process

- Removing Viral Contaminants During Downstream Bioprocessing

- Viral Clearance Testing – Confirming Downstream Bioprocessing Removes Viral Contaminants

Where Does Viral Contamination Come From?

Viral contamination comes from multiple sources. According to the ICH Q5A guidance document, viral contaminants fall into two categories:

- Viral contaminants found in cell banks. Endogenous and latent viruses are present in the cell bank (ex: retroviruses). They are constitutively expressed and transmitted through sequential cell passage.

- Viral contaminants that enter the process during production. Adventitious viruses are those that are introduced during production through contaminated materials or operator handling.

Mitigating the Risk of Viral Contamination

Viral safety relies on a foundation of regulatory guidance, manufacturing quality systems, and good process design. Comprehensive risk analysis helps prioritize mitigation actions and develop a roadmap to outline responsibilities in the event of contamination.

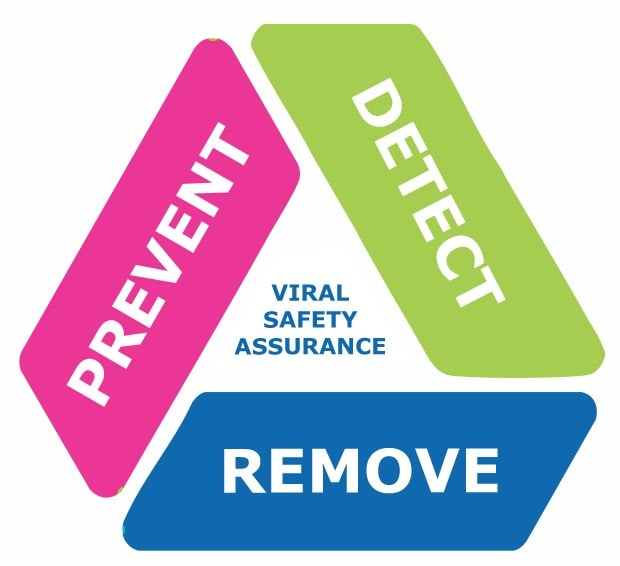

To mitigate the risk of viral contamination, biomanufacturers use the following framework:

- Prevent: Prevent contamination from entering the process through careful selection of cells and raw materials

- Detect: Perform comprehensive testing of raw materials and intermediates to detect viral contaminants

- Remove: Incorporate technologies to remove or inactivate viruses that might be present during downstream purification

Preventing Upstream Viral Contamination

Careful selection and sourcing of materials is the foundation of every biomanufacturing process; regulatory guidance for upstream viral safety is focused on cell line characterization and control of raw materials of animal origin. For selecting raw materials, alternatives to animal-derived products should be used wherever possible. Chemically-defined media reduces the risk of contamination and assures more lot-to-lot consistency. And, if you use animal-derived components, materials sourced from low-risk geographies or those that have been treated with gamma or UV irradiation or tested for the presence of virus should be used. For high risk components such as glucose, high temperature short time (HTST) treated solutions offer a convenient, targeted risk mitigation solution that arrives ready to use.

Beyond raw materials, viral safety relies on well trained operators and technologies such as single-use systems or different options for cell culture media filtration to minimize the risk of adventitious viral or microbial contamination.

Any mitigation approach will incur costs and should be balanced against the potential cost of a contamination event which will likely include discarding one or more batches, full facility cleaning, lost processing time, extensive investigation, and remediation efforts. Understanding the overall costs of contamination may justify the increased costs of viral risk mitigation actions.

Detecting Viral Contaminants Throughout the Process

Raw material selection and testing is key to preventing viral contamination entering the production process while comprehensive cell line characterization ensures the absence of adventitious viruses. Master Cell Bank (MCB) characterization requires broad specificity in vitro and in vivo virus assays as well as assays that target both specific viruses or specific types of viruses such as endogenous retroviruses. Working Cell Banks (WCB), undergo more limited testing while End-of-production (EOP) cells are tested extensively for viral contaminants that may be present, but not detected, in the MCB.

In addition to cell banks and raw materials, key process intermediates, such as the bulk harvest, should be tested for adventitious virus and microbial contaminants.

In some instances, traditional testing methods can augmented or replaced by rapid molecular test methods that enable you to make real-time decisions on in-process material, accelerating your drug productions; examples include the Blazar™ Platform and Next Generation Sequencing (NGS).

Removing Viral Contaminants During Downstream Bioprocessing

Downstream processing involves purifying clarified bulk harvest through sequential steps to enrich and concentrate the molecule of interest, separating it from impurities and viral contaminants. Some of these purification steps also remove or inactivate viral contaminants.

Protein A capture chromatography is usually the first step in mAb downstream purification. In this step, Protein A resin, captures the antibody or recombinant protein, while other impurities flow through. Bound material is then eluted by disrupting non covalent bonds. This single step yields a relatively pure product and is often assessed for viral clearance.

Viral inactivation and polishing steps in downstream processing of multiple modalities provide some level of viral clearance. Exposure to low pH, detergent or heat are commonly used for inactivation of enveloped viral contaminants. Polishing steps with ion exchange chromatography remove different process and product related impurities and clear both enveloped and non-enveloped viruses.

Virus filtration is a core component of viral safety assurance for monoclonal antibodies and recombinant proteins, and is considered a robust processing step relying on virus retention based on size exclusion. Impurities such as protein aggregates, can sometimes cause premature fouling of virus filters, but their impact can often be mitigated by adsorptive prefiltration.

Viral Clearance Testing – Confirming Downstream Bioprocessing Removes Viral Contaminants

Viral clearance studies assess the clearance capabilities of individual process steps and focus on steps that inactivate viruses, such as low pH hold, or steps that remove potential viral contaminants, such as chromatographic separation or virus filtration. To know more, watch our webinar on How Will ICH Q5A(R2) Affect the Design of Virus Clearance Studies?

Before performing clearance studies, a scale-down model of the full-scale process must be developed, and performance confirmed by comparing process parameters and output results at different scales. If results align, the viral clearance capabilities of the small-scale process can be expected to predict clearance capabilities of the large scale process.

The requirements for validation of clearance capability depend on regulatory guidelines and the stage of clinical development. Before a Phase I trial, studies are performed with an enveloped virus such as Murine Leukemia Virus (MuLV), a model for endogenous retroviruses, and a small, non-enveloped virus, usually a parvovirus such as minute virus of mice (MMV). Clearance of these viruses is assessed over a limited number of process steps each with complementary mechanisms of virus reduction. At later stages of clinical development, before license application, comprehensive studies are performed with a panel of viruses, over multiple process steps, and under a range of processing conditions. These late-stage studies evaluate viral clearance under worst-case conditions within the range of processing parameters for each individual process step.

Understanding the results of clearance studies helps inform risk-based decisions on the viral safety of the product.

Don’t Get Left Behind

Join us to receive curated insights and resources to help you navigate the complex landscape of drug development and production.

Download Our Viral Safety Handbook

To get even more details on overcoming the challenges viral safety during bioprocessing, download our Viral Safety eHandbook. This eHandbook provides information on each of these important approaches for ensuring that biotherapeutics are safe for administration to patients and include sections on preventing viral contamination, detecting viral contamination, and removing viruses during downstream bioprocessing.

Please fill out the form below to receive our eHandbook. If you would like to request more information on viral safety or would like to be contacted by one of our representatives, please indicate in the box.

如要继续阅读,请登录或创建帐户。

暂无帐户?