Sol-Gel Science for Ceramic Materials

Introduction

Silicon-based research has drawn much attention in recent years with targeted organizations such as the International Sol-Gel Society hosting workshops,1 and the Sol-Gel Gateway2 hosting a compendium of information regarding the sol-gel field including conference information. In addition, peer-reviewed journals such as Journal of Sol-Gel Science and Technology, Chemistry of Materials, and Journal of Non- Crystalline Solids publish a significant number of articles that focus on silicon-based materials. These organizations, conferences, and journals highlight much of the major siliconbased research generated in academia and industry. Research involving reactive silicone chemistry has focused on the production of pure silicon and hybrid materials, hydrosilylation, ring-opening and atom transfer polymerizations, polymerizations with controlled stereochemistry, and condensation reactions. Reactions with silicones produce a wide range of materials that encompass the major areas of silicon chemistry: polymers, elastomers, ceramics, interpenetrating networks, reinforcing fillers, membranes, microlithography, photoinitiation, high performance polymers, and sol-gel-derived ceramic precursors.

While it was known earlier, sol-gel chemistry has been investigated extensively since the mid-1970’s, when sol-gel reactions were shown to produce a variety of inorganic networks that can be formed from metal alkoxide solutions.3 Through sol-gel processing, homogeneous, high-purity inorganic oxide glasses can be made at ambient temperatures rather than at the very high temperatures required in conventional approaches. Various products, such as molded gels,4,5 spun fibers,6,7 thin films,8-10 molecular cages,11,12 and xerogels13 have been developed for utility in such areas as gas separations, elastomers, coatings, and laminates. It is through the inorganic component incorporation into organic polymers that a wide variety of desired property modifications can be achieved.

The precursors used in sol-gel processing consist of a metal or metalloid element surrounded by various reactive ligands. Metal alkoxides, such as aluminates, titanates and zirconates, are the most popular precursors because of their high reactivity towards water. The most widely used non-metal alkoxides are alkoxysilanes, such as tetramethoxysilane (TMOS, Prod. No. 679259) and tetraethoxysilane (TEOS, Prod. No. 333859). Although ethyl groups are the most common alkoxy groups, methoxy, propoxy, butoxy and other long-chain hydrocarbon alkoxy groups are also used in alkoxysilanes. Metal alkoxides are commonly used in the sol-gel process either alone or in combination with non-metal alkoxides such as TEOS or alkoxyborates.

Sol-Gel

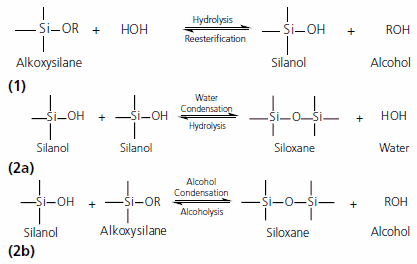

The sol-gel process consists of a series of hydrolysis and condensation reactions of an alkoxide, which proceed according to the reaction scheme shown in Figure 1. Here, alkoxysilanes are used as an example but all of the metal alkoxides react similarly. Hydrolysis is initiated by the addition of water to the silane solution under acidic, neutral, or basic conditions.

Figure 1.Sol-Gel Reaction Scheme.

While hydrolysis and condensation reactions of most metal alkoxides can be carried out without catalyst because of the extremely fast rates of reaction, alkoxysilanes hydrolyze much more slowly, requiring the addition of either an acidic or basic catalyst. In order to slow down the reaction kinetics of the metal alkoxides, Drying Chemical Control Additives (DCCAs) are often used.14,15 These include tetrahydrofuran, formamide, dimethylformamide, and oxalic acid. DCCAs slow down the reaction kinetics by forming hydrogen bonds with the intermediates in the reaction. The DCCA solvent can be removed by evaporation in order to allow the reaction to progress.

Benefits and Utility

Sol-gel processing is beneficial in the formation of ceramic and glass films for many reasons. It is a simple reaction that does not require exotic materials, catalysts or expensive deposition equipment. Likewise, sol-gel reactions do not employ extreme reaction conditions. The reactions take place at room temperature and require only moderate temperatures to ‘cure’ the gel, removing the water/alcohol that the reaction generates. The properties of the materials prepared using solgel approaches are easy to modify by utilizing an organically modified alkoxide or a variable arm metalloid (for example, an alkoxyborate instead of an alkoxysilane).

Sol-gel processing is commonly used to modify S2 glass fibers (a type of high performance fiberglass) used in composites. Coating glass surfaces with a sol-gel film helps the glass gain strength and resists shattering. Also, sol-gel materials have been used in composites to reinforce existing polymeric structures, such as polyesters,16 Nafion®,17 Surlyn®.18 In all of these applications, sol-gel alkoxysilanes and alkoxytitanates were used as received with a purity of 97% or greater.

Modifing the Sol-Gel Network

A convenient way to modify ceramic and composite materials, such as those referred to in the previous paragraph is through the use of Organically Modified Silicates (ORMOSILs). ORMOSILs are derived from tetrafunctional silicon alkoxides such as TEOS, as shown in Figure 2, where n is representative of the number of organic moieties connected to the silicon atom and f is representative of the number of reactive alkoxy groups connected to the silicon. R, R’, and R” are the functional group(s) on an organically modified silicate such as methyl, vinyl, or benzyl. Often, the organic moiety includes a reactive group such as an amine or epoxide, which makes possible subsequent reactions.

Figure 2.Functionality of ORMOSILs

Silsesquioxanes are other widely used inorganic-organic modifiers in ceramic and composite materials. Bridging silsesquioxanes (Figure 3) contain a substituent (R) that is hydrocarbon based but can also contain organic spacer functionalities. Since silsesquioxanes are often incorporated into polymer systems, the R-group should be as similar as possible to the repeat unit thus increasing interface compatibility.

Figure 3.Examples of a 6-arm and a 4-arm Bridging Silsesquioxane.

In addition, numerous caged structures are being incorporated into ceramic and composite materials through sol-gel chemistries. These structures, such as polyhedral silsesquioxanes19,20 (also commonly known as PSS) or zeolites,21 add specific porosity and rigidity to the material. Caged structures can be incorporated through non-covalent (trapping the material within the ceramic structure) or covalent bonding.

Studying Sol-Gel Networks

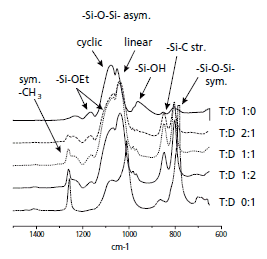

Sol-gel bonding in ceramic and composite structures is often studied through FTIR and solid-state NMR (29Si MAS NMR for example). Elemental ratios can be determined via XPS for surfaces and through prompt γ neutron activation analysis for bulk materials. Figure 4 shows FT-IR data from a sol-gel ORMOSIL of tetraethylorthosilicate (T):diethoxydimethylsilane (D) sol-gels polymerized within a Nafion structure delineating different silicon bond structures.22 The prominent absorbance is due to the asym metric Si-O-Si envelope, consisting of both the cyclic (~1080 cm-1) and linear (~1030 cm-1) components.

Figure 4.FT-IR ATR Difference Spectra for Tetraethylorthosilicate (T): Diethoxydimethylsilane (D) sol-gels polymerized within a Nafion structure.22

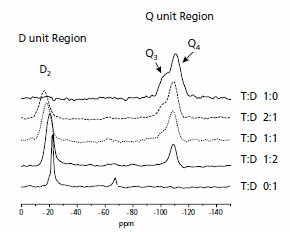

Figure 5.Shows solid-state 29Si MAS NMR data from ORMOSIL tetraethylorthosilicate/diethoxydimethylsilane polymerized within a Nafion structure delineating different silicon bond structures.

Conclusion

Sol-gel science and technology have the potential to make a significant impact in modification of the properties of materials. One of the most significant benefits of sol-gel science is its use of room temperature conditions and insensitivity to the atmosphere. These features will allow its use with various materials that cannot tolerate high temperatures, and does not limit the researcher to using special equipment, such as a dry box.

Materials

References

To continue reading please sign in or create an account.

Don't Have An Account?