Base Resins for Peptide Synthesis

The Novabiochem® product line has one of the most extensive ranges of polymer-supports for solid phase peptide synthesis. They range from high-loaded, low swelling for the large scale production of relatively short peptides to high-swelling, low-loaded for the synthesis of long or difficult sequences.

For peptide synthesis, the use of small particle-sized resins of low crosslinking is favored. Such resins allow for rapid diffusion of reagents inside the beads and their swelling enables them to better accommodate the bulk of the growing peptide chain. The most commonly used resins are based on 1% divinylbenzene-crosslinked polystyrene. These are relatively low-cost, easy-to-handle, and have high substitution. They are normally employed for batch-wise synthesis, with gas-bubbling, shaking, paddle stirring, or vessel inversion used for mixing. However, they can also be used in continuous flow synthesis, provided a low flow-rate is used or the resin is co-packed with glass beads, although for this application NovaSyn® TG, NovaGel™, or PEGA composite resins are preferred. Here, the solvation of the PEG confers pressure stability on the polymer, making them suitable for use in pumped-flow systems.

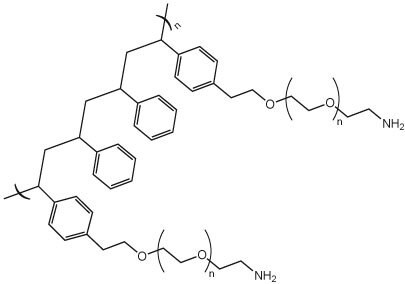

NovaSyn® TG resins

NovaSyn® TG and NovaSyn® TGR resins1 are based on a composite of low cross-linked hydroxyethylpolystyrene and polyethylene glycol, which has been terminally functionalized. NovaSyn® TG resin is available as 90 µm and 130 µm beads. The smaller bead size resin is generally preferred for peptide synthesis and peptide libraries; 1 g contains almost a sufficient number of beads to represent a pentameric peptide library. The higher capacity of the large beads make the 130 µm resin ideal for the production of non-peptidic libraries.

These resins are suitable for both continuous flow and batch peptide synthesis. The NovaSyn® TGR resins have been specifically designed for the synthesis of long and challenging sequences. They have excellent physical stability in flow systems, are resistant to abrasion and mechanical pressure, and offer improved chemical efficiency. High flow rates have even been reported to increase the acylation and deprotection rates of NovaSyn® TG resins2. NovaSyn®TG resins are also recommended for use with the one-bead-one-compound approach to chemical libraries. The beads have a narrow size distribution and swell in water, facilitating biological assays in aqueous systems. The resins swell in a wide range of solvents from toluene to water, and the environment provided by the PEG is thought to closely resemble that found in THF.

The PEG is anchored in NovaSyn®TG resins to the polystyrene backbone via an acid insensitive ethylphenyl ether. PEG leakage that many report as being associated with the use of these resins is not due to any inherent acid instability, but arises through formation of PEG peroxides by the actions of oxygen and light during long-term storage. This degradation is an intrinsic property of all PEG resins. Unfavorable comparisons made between NovaSyn®TG and other similar PEG-based supports almost certainly reflect differences in age and storage histories of the samples tested and not any fundamental differences in chemical stability.

Figure 1.Structure of NovaSyn® TG resin.

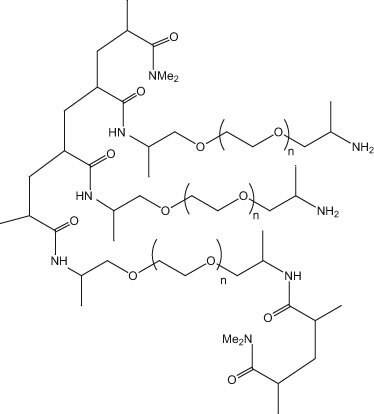

PEGA resins

PEGA resins are hydrophilic polymers that were originally developed for batch and continuous flow peptide synthesis4 but which are also used in SPOS. They consist of 2-acrylamidoprop-1-yl-(2-aminoprop-1-yl) polyethylene glycol800 and dimethylacylamide cross-linked with bis 2-acrylamidoprop-1-yl polyethylene glycol800. These supports swell extensively in a wide range of solvents, including water, DMF, DCM, THF and MeOH, and are freely permeable to macromolecules up to 35kD, making them ideally suited for the preparation of peptide libraries, affinity purification, and on-resin enzyme assays. These properties have been exploited in the on-resin enzymatic synthesis of glycopeptides [5]; for determining the inhibitors of subtilisin Carlsberg6, Cruzipain7, cysteine proteases8, and matrix metalloproteinases9; and in studies on protein disulfide isomerases, using fluorescence-quenched libraries10.

Smith & Bradley11 compared solution and solid phase polyamine libraries in an assay against trypanathione reductase. The library on PEGA resin performed as well as that in solution, whilst the library on TG resin failed to work.

Figure 2.Structure of PEGA resin

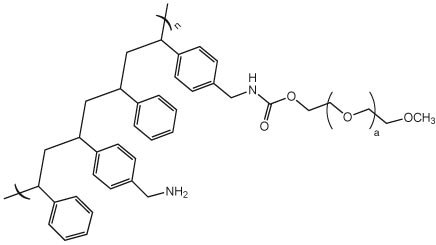

NovaGel™ resins

NovaGel™, also know as Champion resin, is a type of PEG-PS resin that has been designed to meet the requirements of chemists for resins of high substitution with broad solvent compatibility. It is prepared from a special high-swelling version of aminomethylated resin by partial derivatization with methyl-PEG2000-p-nitro-phenylcarbonate2-3. This produces a resin containing approximately 48% PEG, with a substitution of 0.7 mmole/g, which is almost twice that of conventional PEG-PS supports. It swells in solvents of such widely different polarities as THF, DMF, acetonitrile and methanol, making it an excellent support for both peptide and organic synthesis.

The urethane linkage between the PEG and the base resin is stable to piperidine and TFA, ensuring minimal loss of PEG chains during synthesis. However, if leaching of PEG does occur, this does not result in loss of substitution, as can be the case with other PEG-PS-based resins, because the linker is not attached to the end of the PEG chains.

Figure 3.Structure of NovaGel™ resin

Materials

References

如要继续阅读,请登录或创建帐户。

暂无帐户?