生物制药4.0:数字化转型

对新型疗法日益增长的需求、持续的成本削减压力以及创新治疗模式的成功,正推动着生物制药行业的变革。

无论称之为生物技术数字化、生物加工4.0还是未来生物制造工厂,都需平衡多重目标。 为保持竞争力,新兴与成熟生物技术企业及合同研发制造组织(C(D)MO)必须在不牺牲质量与合规的前提下,提升速度、效率、敏捷性及可扩展性。在此基础上,还需创造更高价值并契合企业可持续发展目标——所有这些都需在高度监管的环境中实现。

数字化生物制造:迈向未来封闭式生产设施的进化之路

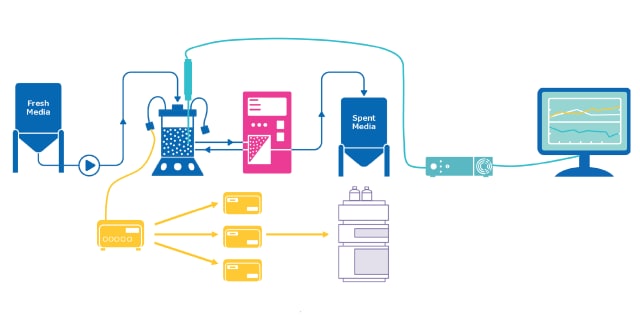

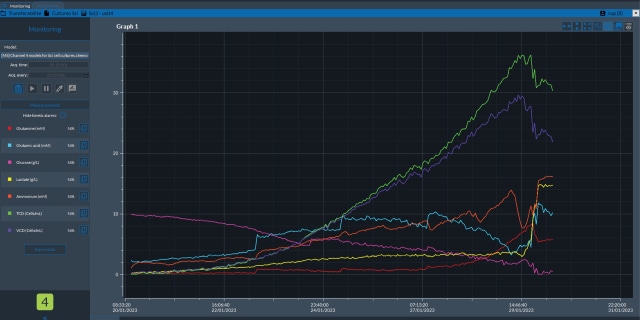

您的数字化转型将加速全球患者获得生物制药的进程。为助力您在不同制备模式和生产规模下实现雄心勃勃的生物制造目标,我们提供涵盖上游与下游工艺的先进封闭式处理就绪技术,构建融合型端到端解决方案。结合过程分析技术(PAT),我们的数据分析、自动化及控制软件将推动单元、工厂乃至企业层面的数字化成熟度提升。

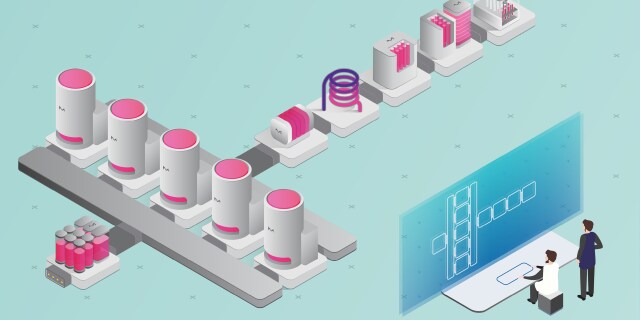

无论您选择何种发展路径——开发强化或连续生物工艺,抑或打造未来的自主化生产设施——BioContinuum™平台都将提供构建模块与专业知识,助您实现性能与生产力的全新突破。

BioContinuum™平台:助您打造未来生物制造设施的利器!

强化与持续上游(USP)处理

- 种子列车强化

- 生产与收获强化

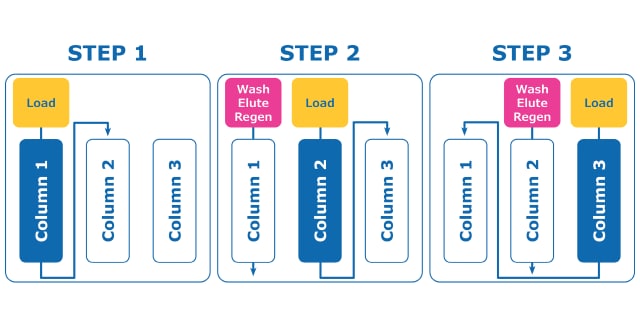

强化与持续的下游处理(DSP)

- 强化捕获

- 病毒灭活

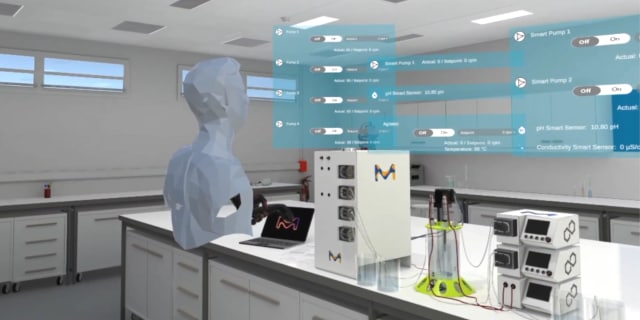

过程分析技术(PAT)

- 拉曼光谱学

- 自动化无菌采样

生物工艺数据分析软件

- Bio4C ProcessPad™ 软件

生物加工自动化与控制软件

- Bio4C ACE™ 软件

生物制造的封闭式处理

- 生物加工连接/断开

- 无菌采样

- 切向流过滤器及系统

- 最终无菌过滤与灌装

登录以继续。

如要继续阅读,请登录或创建帐户。

暂无帐户?